Business Administration > QUESTIONS & ANSWERS > Lehigh University_Solutions Manual: Ch03-Flow & Batch-s Review Questions 3.1 What does sequential op (All)

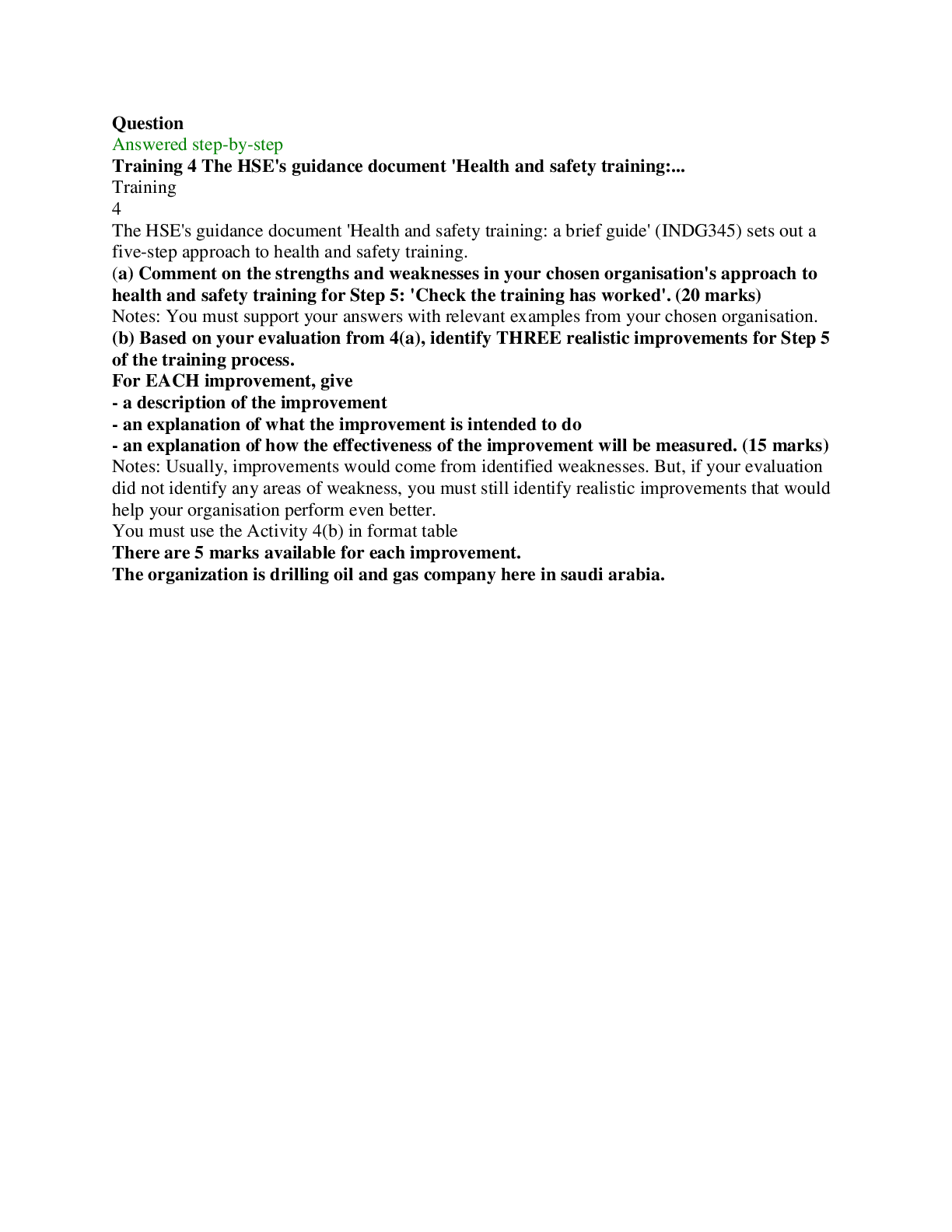

Lehigh University_Solutions Manual: Ch03-Flow & Batch-s Review Questions 3.1 What does sequential operations mean? What is a precedence constraint in sequential operations? What is the difference between pure sequential work flow and mixed sequential work flow? Name and define the four types of part moves between workstations in sequential operations. What is a From-To chart? What is a bottleneck in sequential operations?

Document Content and Description Below

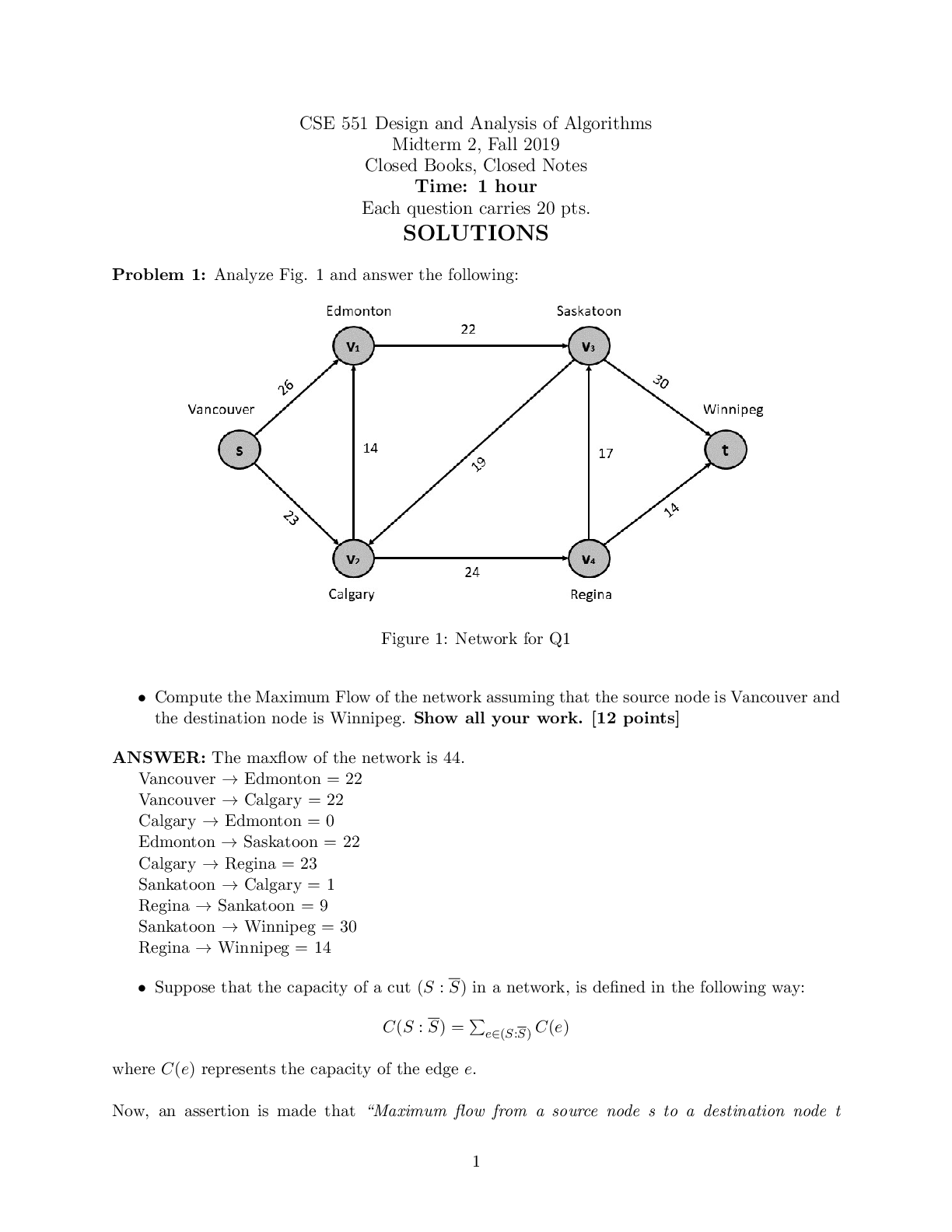

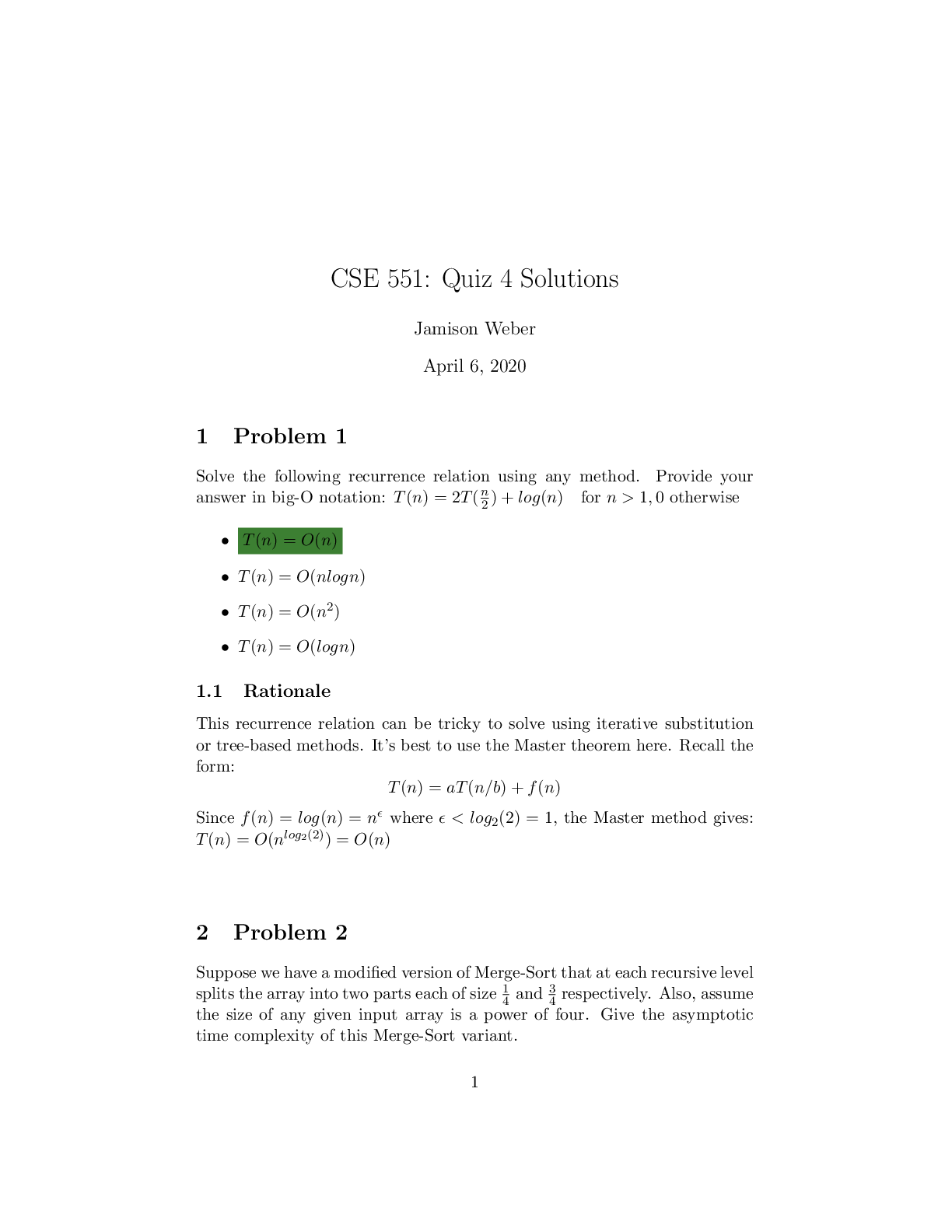

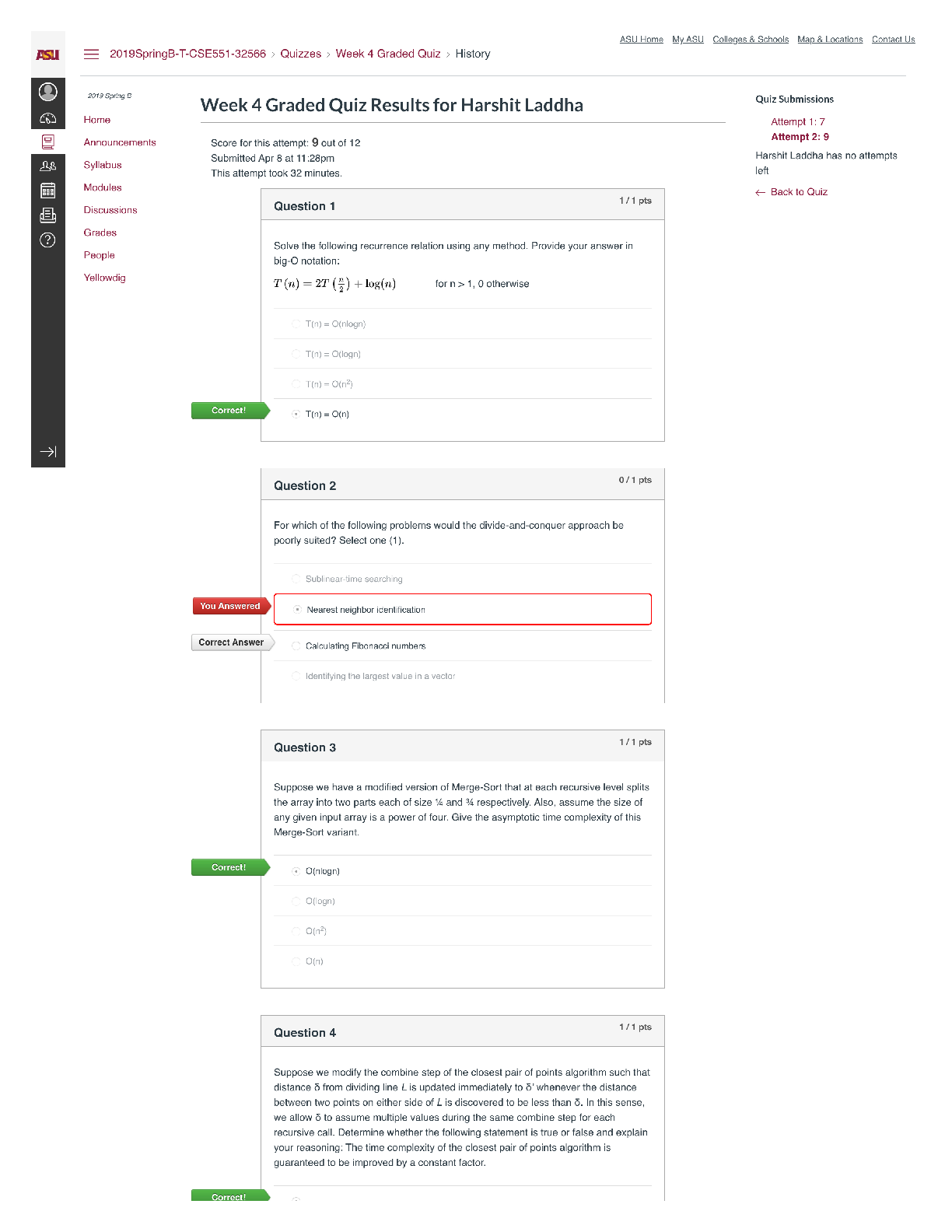

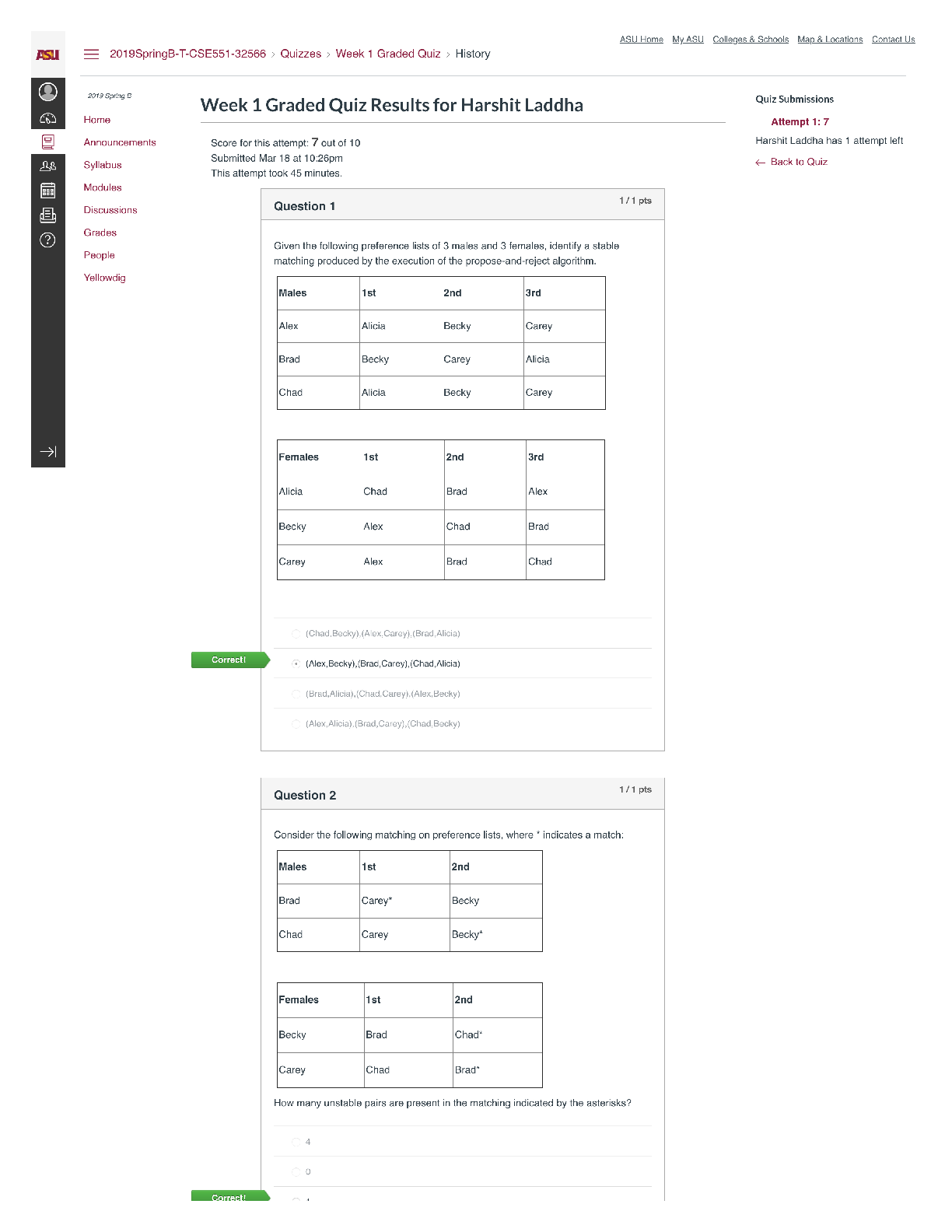

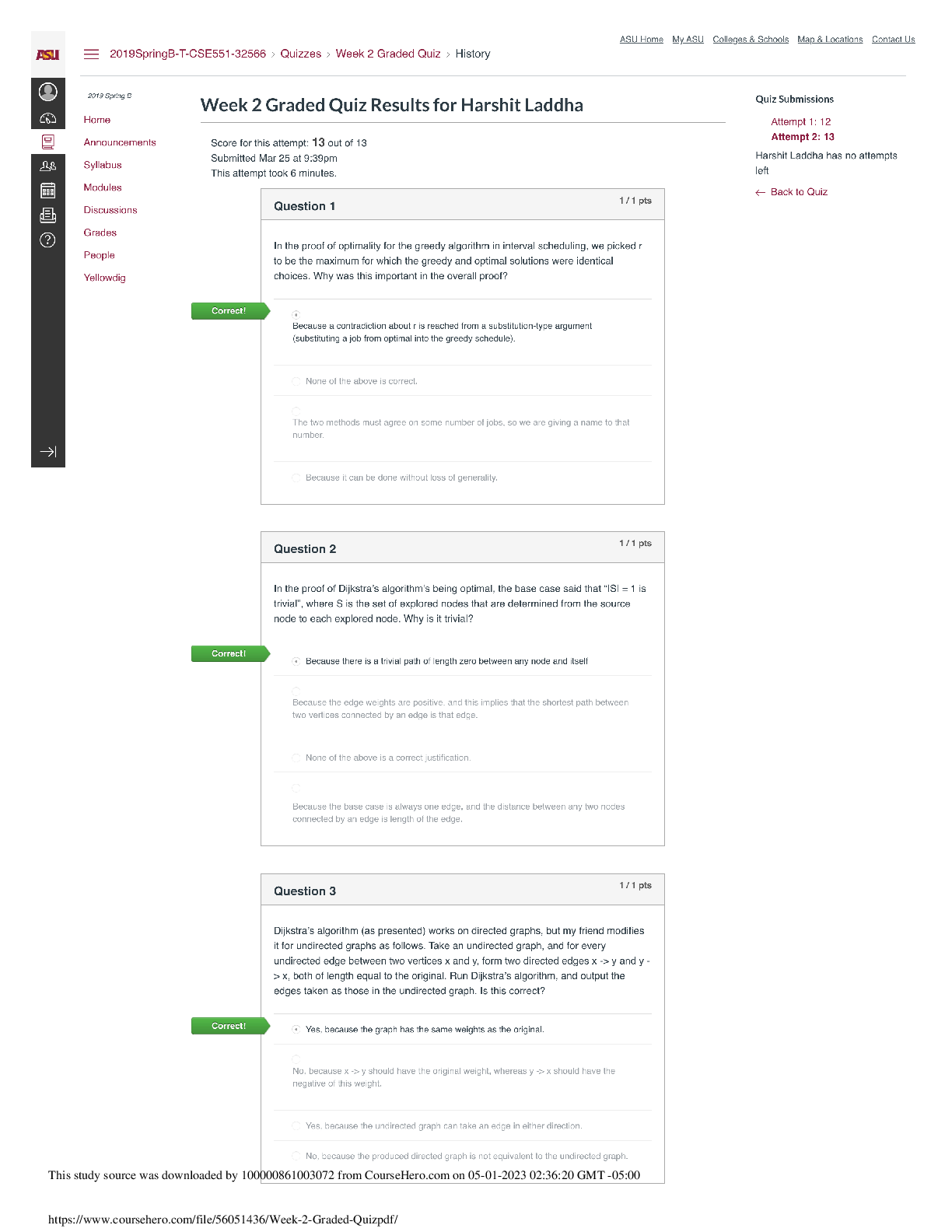

Solutions Manual: Ch03-Flow & Batch-s Review Questions 3.1 What does sequential operations mean? Answer: As defined in the text, sequential operations are a work system in which multiple processin... g steps are accomplished in order to complete a work unit, and the processing steps are performed sequentially (rather than simultaneously). 3.2 What is a precedence constraint in sequential operations? Answer: A precedence constraint is a restriction on the order in which the sequence of operations must be performed. Certain operations must be accomplished before other operations can be started. The example given in the text is drilling and tapping. A hole must be drilled before it can be tapped. 3.3 What is the difference between pure sequential work flow and mixed sequential work flow? Answer: Pure sequential means that all work units flow through the same exact sequence of workstations and operations. There is no variation in the processing sequence. Mixed sequential means that there are variations in the work flow for different work units. Different work units are processed through different stations. 3.4 Name and define the four types of part moves between workstations in sequential operations. Answer: The four types of part moves identified in the text are: (1) in-sequence move, in which the work unit moves forward from the current operation to the neighboring operation immediately downstream; (2) bypassing move, which is a forward move beyond the neighboring workstation by two or more stations ahead of the current station; (3) backflow move, in which the work unit moves in the backward direction by one or more stations; and (4) repeat operation, in which the operation is repeated at the same workstation and the part does not move between stations. 3.5 What is a From-To chart? Answer: A From-To chart is a tabular chart that is used to indicate various quantitative relationships between operations or workstations in a multi-station work system. Typical quantities displayed in a From-To chart include quantities between stations, flow rates of parts between stations, and distances between stations. 3.6 What is a bottleneck in sequential operations? Answer: The bottleneck operation is the slowest operation in the sequence. It is the operation that ultimately limits the production rate of the sequence. 3.7 What do the terms starving and blocking mean in terms of sequential operations? Answer: Blocking means that the production rate(s) of one or more upstream operations are limited by the rate of a downstream operation. The upstream operations are blocked by the slower rate of the downstream station. Starving means that the production rate(s) of one or more downstream operations are limited by the rate of an upstream operation (e.g., the 1 .Solutions Manual: Ch03-Flow & Batch-s bottleneck). The downstream operations can work no faster than the rate at which the bottleneck feeds work units to them. 3.8 What does the term batch processing mean? Answer: As defined in the text, the term batch processing refers to the processing of work units in finite quantities or amounts. 3.9 What are some of the disadvantages of batch processing? Answer: The disadvantages of batch processing include the following: (1) batch processing is discontinuous, which means there are periods in which the equipment is not producing; (2) delays occur between processing steps when batch processing is used in conjunction with sequential operations; (3) queues of work units form in front of operations, resulting in high work-in-process inventories; and (4) long lead times occur due to accumulation of work-in-process. 3.10 Given the disadvantages of batch production, what are the reasons why it is so widely used in industry? Answer: The reasons given in the text are (1) work unit differences that require changeovers in processing equipment, (2) equipment limitations such as the capacity of equipment, and (3) material limitations, in which the material must be processed as a unit of material. 3.11 What are the two cost terms in the economic order quantity model? Answer: The two cost terms in the economic order quantity model are (1) setup or changeover cost and (2) inventory holding cost. 3.12 Write the equation that describes the relationship between the starting quantity of work units Qo, the completed quantity Q, and the fraction defect rate q of the operation processing the work units. Answer: The equation is Q = Qo(1 – q) 3.13 What is a work cell? Answer: As defined in the text, a work cell is a group of workstations dedicated to the processing of a range of work units within a given type. 3.14 What is a worker team? Answer: A worker team is a collection of workers who are brought together to achieve a common objective or solve a common problem. 3.15 Define teamwork. Answer: Teamwork refers to the cumulative efforts of the team members to achieve a result that is greater than the sum of their individual efforts. It requires the subordination of the members’ individual goals in favor of the team’s goals. 3.16 What is the difference between a work-unit team and a self-managed work team? Answer: A work-unit team is one that consists of all the workers employed in a department or unit. It is basically an extension of the regular organizational structure, 2 .Solutions Manual: Ch03-Flow & Batch-s except that the management of the organization is attempting to instill a spirit of teamwork among the work-unit members. A self-managed work team operates like a separate business unit in the organization. It elects its own leaders, and plans and manages its own activities. Management provides the resources necessary for a self-managed team to operate, but the team basically runs itself. 3.17 What is cross-training and what is its value in a worker team? Answer: Cross-training means workers become trained in more than one job in the work unit or cell. Although each individual brings unique knowledge, skills, and abilities to the team’s activities, having more than one team member know each job mitigates problems of absences and allows for job rotations to increase work variety and employee satisfaction. 3.18 Name some examples of cross-functional teams. Answer: Examples given in the text are: (1) concurrent engineering teams, who work on product design projects; (2) task forces, which are usually assembled to deal with a significant organizational problem or exploit a commercial opportunity; and (3) crisis management teams, which are designed to cope with a crisis or disaster that occurs. Problems Workflow Structures 3.1 Four parts (A, B, C, and D) are processed through a sequence of four operations (1, 2, 3, and 4). Not all parts are processed in all operations. Part A, which has weekly quantities of 70 units, is processed through operations 1, 2, and 3 in that order. Part B, which has weekly quantities of 90 units, is processed through operations 2, 4, and 1 in that order. Part C, which has weekly quantities of 65 units, is processed through operations 3, 2, and 4 in that order. Finally, part D, which has weekly quantities of 100 units, is processed through operations 2, 1, and 4 in that order. (a) Draw the network diagram and (b) prepare the From-To table for this work system. Solution: (a) Network diagram. 1 2 4 3 90 100 70 65 70 100 90+65 (b) From-to chart From\To 1 2 3 4 1 70 70 100 2 100 155 3 65 4 90 3 .Solutions Manual: Ch03-Flow & Batch-s 3.2 Five parts (A, B, C, D, and E) are processed through a sequence of five operations (1, 2, 3, 4, and 5). Not all parts are processed in all operations. Part A, which has daily quantities of 50 units, is processed through operations 1, 3, 5, and 1 in that order. Part B, which has daily quantities of 70 units, is processed through operations 2, 4, and 5 in that order. Part C, which has daily quantities of 25 units, is processed through operations 3, 2, and 4 in that order. Part D, which has daily quantities of 10 units, is processed through operations 1, 2, 4, and 5 in that order. Finally, part E, which has daily quantities of 15 units, is processed through operations 3, 1, and 2 in that order. (a) Draw the network diagram and (b) prepare the From-To table for this work system. Solution: (a) Network diagram 1 2 3 4 5 50 70+25+10 50 25 15 70+10 50 10+15 (b) From-to chart From\To 1 2 3 4 5 1 25 50 2 105 3 15 25 50 4 80 5 50 Bottleneck Operations 3.3 A factory produces cardboard boxes. The production sequence consists of three operations: (1) cutting, (2) indenting, and (3) printing. There are three automated machines in the factory, one for each operation. The machines are 100% reliable and the scrap rate in each operation is zero. In the cutting operation, large rolls of cardboard are fed into the cutting machine, which cuts the cardboard into blanks. Each large roll contains enough material for 4000 blanks. Production time = 0.03 min/blank during a production run, but it takes 25 min to change rolls and cutting dies between runs. In the indenting operation, indentation lines are pressed into the printed blanks that allow the blanks to later be bent into boxes. Indenting is performed at an average time of 2.5 sec. per blank. Batches from the previous cutting operation are subdivided into two smaller batches with different indenting lines, so that starting batch size in indenting = 2000 blanks. Time to change dies between batches on the indenting machine = 30 min. In printing, the blanks are printed with labels for a particular customer. Starting batch size in printing = 2000 blanks (these are the same batches as in indenting). Production rate = 30 blanks/min. Between batches, changeover of the printing plates is required, which takes 40 min. What is the maximum possible output of this factory 4 .Solutions Manual: Ch03-Flow & Batch-s [Show More]

Last updated: 2 years ago

Preview 1 out of 17 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$4.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Jan 14, 2023

Number of pages

17

Written in

Additional information

This document has been written for:

Uploaded

Jan 14, 2023

Downloads

0

Views

88