Engineering > STUDY GUIDE > Activity 7.3 Answer Key _ Introduction to Engineering Design Teacher Edition (All)

Activity 7.3 Answer Key _ Introduction to Engineering Design Teacher Edition

Document Content and Description Below

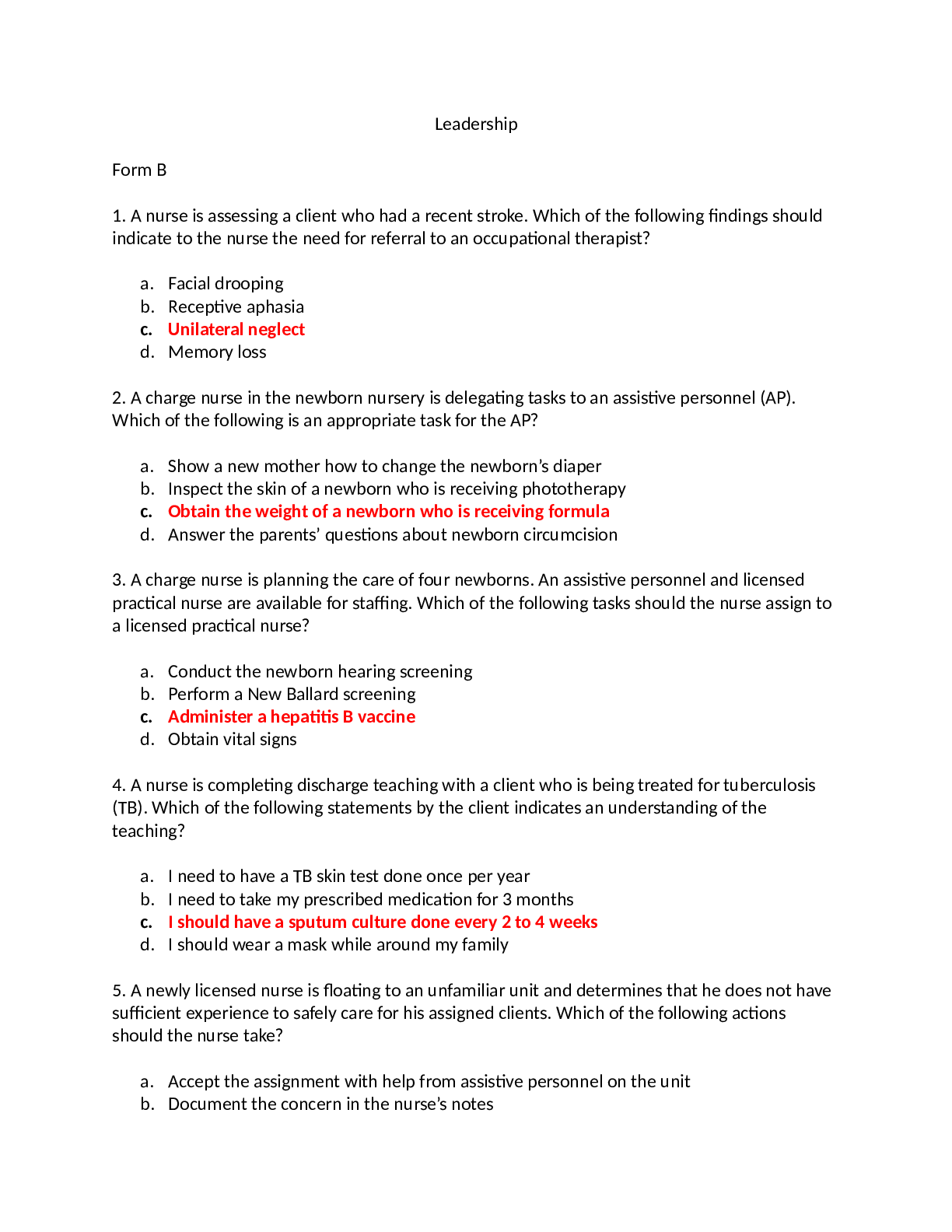

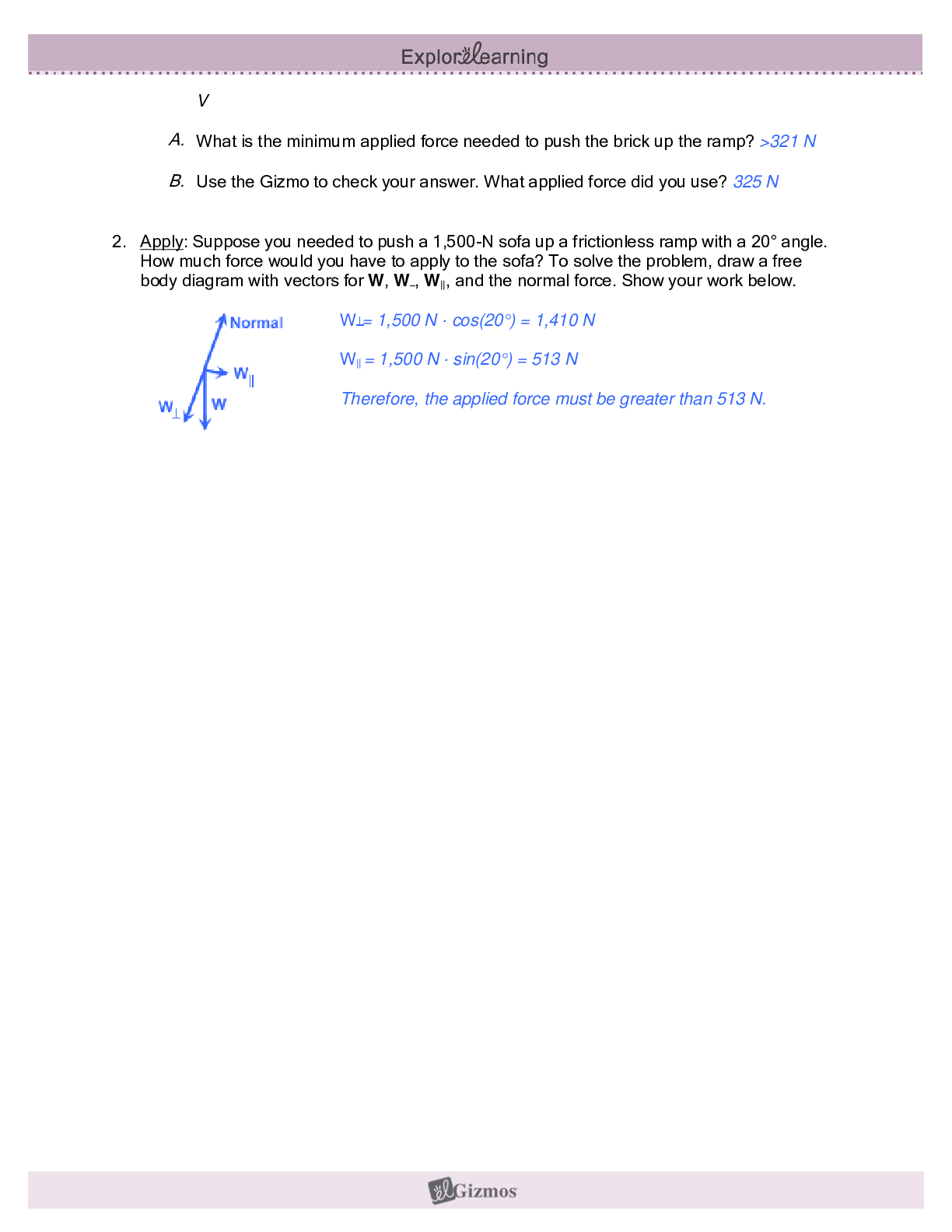

TEACHER EDITION Activity 7.3 Tolerances Answer Key Procedure Study the drawings below to identify specified tolerances. a. Highlight each dimension that has a tolerance associated wit... h it using something like a highlight marker. b. Identify the type of tolerance in each highlighted example by labeling each tolerance dimension with one of the following: limit dimensions, unilateral tolerance, or bilateral tolerance. c. Label each identified tolerance with a separate letter, A through Z. d. Beginning on a new page in your engineering notebook for each part, record the letter of each tolerance identified on that part drawing, the type of tolerance, a short written phase that describes the dimensional variation allowed for that dimension, the tolerance (a number representing the total allowed dimensional variation), and an explanation as to why that particular dimension requires a tolerance. You may wish to duplicate the following table in your notebook to organize your notes. Letter Tolerance Type Written Explanation Tolerance Why? A LIMIT Dimension x 0.005 in. To accommodate DIMENSIONS is 0.531 in. ≤ dimensional x ≤ 0.536 in. variations and/or fit of shaft that fits in hole B LIMIT Dimension x 0.005 in. To accommodate DIMENSIONS is 0.750 in. ≤ dimensional x ≤ 0.755 in. variations and/or the fit of shaft that fits in hole C LIMIT Dimension x 0.005 in. To accommodate DIMENSIONS is 0.590 in. ≤ dimensional x ≤ 0.595 in. variations and/or fit of shaft that fits in hole Letter Tolerance Type Written Explanation Tolerance Why? D UNITALERAL TOLERANCE Diameter may be up to 0.003 in. larger than 0.50 in. but not smaller 0.003 in. To accommodate a tighter fit and more precise alignment between the anchor bolts and the base plate than would be provided by the general tolerances. Note that in many cases the tolerances on the size and location of the anchor bolt holes is generous to allow for misalignment of the anchor bolts when placed in concrete. E BILATERAL TOLERANCE Dimension may be as much as 0.002 in. larger or smaller than 0.25 in. diameter 0.004 in. To accommodate a specific fit between the cylindrical object that fits in the hole and the base plate that would not be accommodated with the general tolerances. F LIMIT DIMENSIONS Dimension x is 2.000 in. ≤ x ≤ 2.003 in. 0.003 in. To limit the location of the center hole (and the inserted cylindrical object). G LIMIT DIMENSIONS Dimension x is 3.000 in. ≤ x ≤ 3.003 in. 0.003 in. To limit the location of the center hole (and the inserted cylindrical object). Part Name: DRILL BLOCK Letter Tolerance Type Written Explanation Tolerance Why? H BILATERAL TOLERANCE Depth of the counter bore may be as much as 0.003 in. larger or smaller than specified depth of 0.250 in. 0.006 in. To force a tighter tolerance (than the general tolerance) to limit the depth of the bolt head from the surface. I LIMIT DIMENSIONS Surface diameter, d, of the countersink hole can vary such that 0.753 in. ≤ d ≤ 0.748 in. 0.005 in. To force a tighter tolerance (than the general tolerance) to provide a more precise fit of the screw head in the hole. J UNITALERAL TOLERANCE Diameter of the thru hole may be up to 0.004 in. larger than 0.500 in. but not smaller. 0.004 in. Potentially to accommodate a specific fit for the object inserted into the hole. K BILATERAL TOLERANCE Location dimension may be as much as 0.05 in. larger or smaller than 1.50 in. diameter. 0.004 in. To loosen the tolerance (from the general tolerance) on the location of the bolt or screw to reduce manufacturing cost where a tighter tolerance is not needed. Consider the adjustable rocker arm represented in the drawing above. An axle is to pass through the smallest hole. The manufacturer is considering buying bar stock for the axle that is manufactured according to the following drawing using the same general tolerances as those specified on the Rocker Arm Drawing. Answer the following questions and SHOW YOUR WORK. a. What is the tolerance (the acceptable amount of dimensional variation) for the diameter of the rod? b. What is the tolerance for the rod length? c. Is the fit between the rod and the hole a clearance fit, interference fit, or transition fit? Explain your answer. d. What is the allowance between the rod and the smallest hole? e. If the design of the assembled machine requires that the rod is sized such that the actual clearance between the rod and the hole is never greater than 0.005 inches, will the current rod design meet the requirement? Explain. f. The machine specification requires that the rod is no longer than 3.025 inches and no shorter than 2.955 in. Let L represent the actual length of the rod. Write the length constraint as a compound inequality. Will the stock rods always meet the length constraint? Explain. g. If the stock rods do not always meet the machine specifications for rod length, how can the manufacturer alter the rod part drawing such that the rod length will always conform to the specifications? Design a rod that will have an interference fit so that the allowance (the maximum interference) is 0.010 with the center hole in the Rocker Arm and the tolerance on the rod diameter is .002. Sketch a section view of your rod design below. Be sure to specify the tolerance in the diameter dimension of your design. Consider the axle pin and the body of the Automoblox vehicle (shown below). The axle is designed to remain inserted into the body of the vehicle so that it cannot be removed by a child. a. What type of fit would you recommend for the axle and body? Why? b. Assume an interference fit is used and that the ideal interference between the axle and the hole in the body of the vehicle is 0.005 inches. However, the interference can increase to as much as .010 without damage to the parts. With the addition of glue to help adhere the two pieces, an interference of .002 can be used successfully. Assume that the specified diameter of the axle is 0.300 inches as shown on the pictorial above. On the images above indicate your recommendation for: The specific tolerance to the axle diameter dimension The diameter and associated tolerance for the hole in the bed c. Calculate the following for the exterior axle pin diameter using your suggested dimension tolerance. SHOW YOUR WORK. Specified dimension: 0.300 inches d. Calculate the following for the diameter of the hole in the body using your dimensioned part drawing. SHOW YOUR WORK. e. Calculate the allowance between the hole and the axle pin diameter based on your recommended dimensions and tolerances. SHOW YOUR WORK. Open the drill block drawing file that you created in Activity 7.2 Sectional Views. The drill block drawing is shown below. Edit the dimensions to show specific tolerances to the following dimensions. Note that instructions for including tolerance specifications on an Inventor drawing are given below. a. A bilateral (symmetric) tolerance of 0.10 inches for the overall length, width, and depth. b. Stack limit dimensions to locate the holes along the depth dimension (2 in.) such that the dimension can vary between the dimension given above and 0.03 inches larger. c. To better control the hole locations, use datum dimensioning for the dimensions along the long dimension (5 in.). Note that the datum location is shown on the drawing above. d. A unilateral (deviation) tolerance of +.003 inches for the counter bore diameter on the 0.25 inch diameter hole. Change the precision of the counterbore diameter to show three digits to the right of the decimal place. e. A bilateral (symmetric) tolerance of 0.002 on the 0.50-inch diameter counter sunk hole. Add the following General Tolerances notes to the drawing. Linear Dimensions Angles = ±.5° X.X = ±.020 X.XX = ±.010 X.XXX = ±.005 Consider the drill block from the item above. a. If the detail drawing used chain dimensioning to locate the holes along the 5 in. dimension as shown in the image below (and therefore the tolerances are additive), what would be the upper and lower limit of the dimension from the left edge to the center of the 0.25-inch diameter hole on the right assuming general tolerances apply? b. What is the upper and lower limit of the dimension from the left edge to the center of the 0.25 inch diameter hole in the drawing you created (using datum dimensioning), assuming general tolerances apply? [Show More]

Last updated: 2 years ago

Preview 1 out of 20 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$8.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Apr 18, 2021

Number of pages

20

Written in

Additional information

This document has been written for:

Uploaded

Apr 18, 2021

Downloads

0

Views

258

.png)