Unit 4 Homework Problems – Page 208 Problems

Question 1

Determine the utilization and the efficiency for each of these situations:

a. A loan processing operation that processes an average of 7 loans per day. The op

...

Unit 4 Homework Problems – Page 208 Problems

Question 1

Determine the utilization and the efficiency for each of these situations:

a. A loan processing operation that processes an average of 7 loans per day. The operation has a

design capacity of 10 loans per day and an effective capacity of 8 loans per day.

b. A furnace repair team that services an average of four furnaces a day if the design capacity is six

furnaces a day and the effective capacity is five furnaces a day.

c. Would you say that systems that have higher efficiency ratios than other systems will always

have higher utilization ratios than those other systems? Explain.

Question 3

A producer of pottery is considering the addition of a new plant to absorb the backlog of demand

that now exists. The primary location being considered will have fixed costs of $9,200 per month

and variable costs of 70 cents per unit produced. Each item is sold to retailers at a price that averages 90 cents.

a. What volume per month is required in order to break even?

b. What profit would be realized on a monthly volume of 61,000 units? 87,000 units?

c. What volume is needed to obtain a profit of $16,000 per month?

d. What volume is needed to provide a revenue of $23,000 per month?

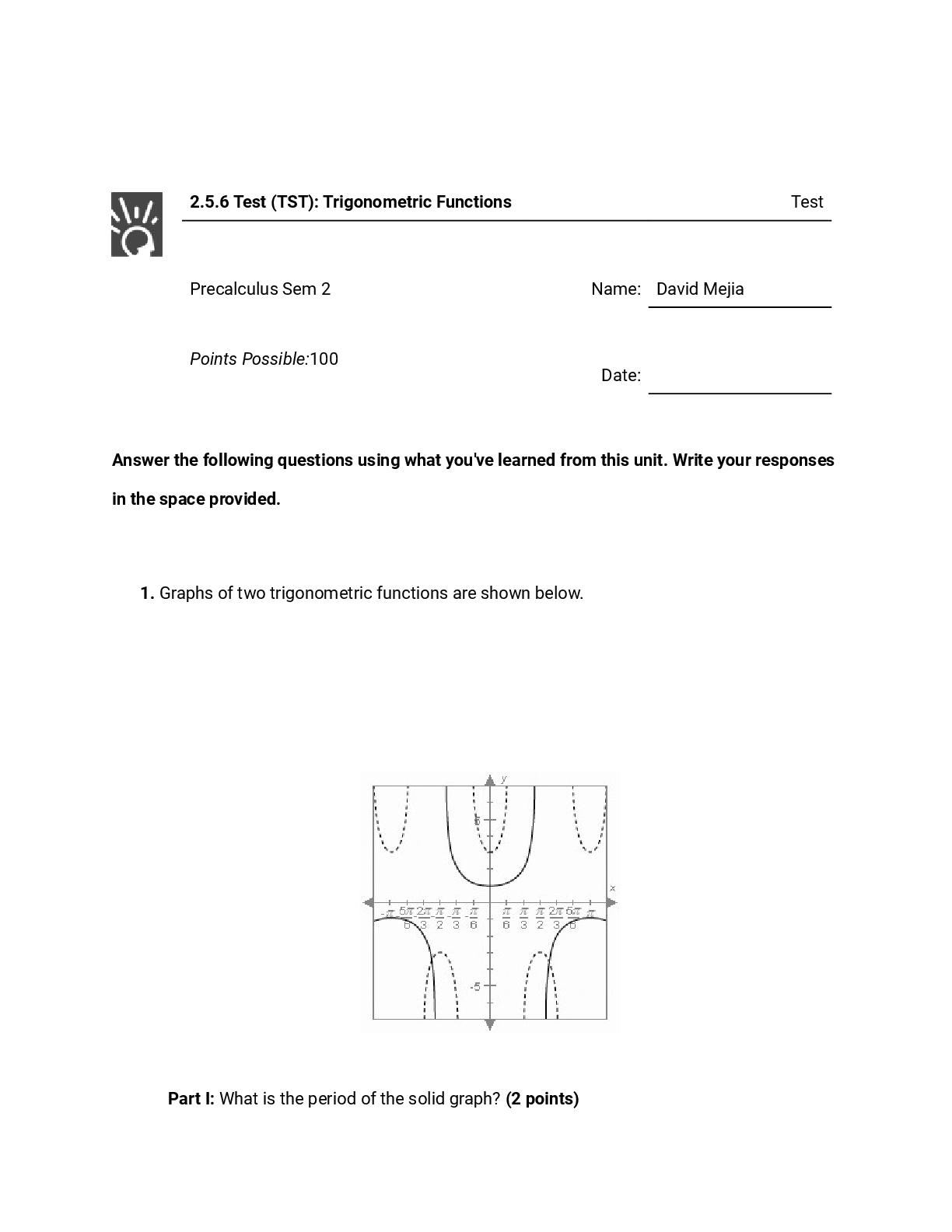

e. Plot the total cost and total revenue lines.

$

Question 5

A producer of felt-tip pens has received a forecast of demand of 30,000 pens for the coming month

from its marketing department. Fixed costs of $25,000 per month are allocated to the felt-tip operation, and variable costs are 37 cents per pen.

a. Find the break-even quantity if pens sell for $1 each.

b. At what price must pens be sold to obtain a monthly profit of $15,000, assuming that estimated

demand materializes?

Question 7

A firm plans to begin production of a new small appliance. The manager must decide whether

to purchase the motors for the appliance from a vendor at $7 each or to produce them in-house.

Either of two processes could be used for in-house production; one would have an annual fixed cost

of $160,000 and a variable cost of $5 per unit, and the other would have an annual fixed cost of

$190,000 and a variable cost of $4 per unit. Determine the range of annual volume for which each

of the alternatives would be best.

Question 8

A manager is trying to decide whether to purchase a certain part or to have it produced internally.

Internal production could use either of two processes. One would entail a variable cost of $17 per

unit and an annual fixed cost of $200,000; the other would entail a variable cost of $14 per unit

and an annual fixed cost of $240,000. Three vendors are willing to provide the part. Vendor A has

a price of $20 per unit for any volume up to 30,000 units. Vendor B has a price of $22 per unit for

demand of 1,000 units or less, and $18 per unit for larger quantities. Vendor C offers a price of $21

per unit for the first 1,000 units, and $19 per unit for additional units.

a. If the manager anticipates an annual volume of 10,000 units, which alternative would be best

from a cost standpoint? For 20,000 units, which alternative would be best?

b. Determine the range for which each alternative is best. Are there any alternatives that are never

best? Which?

[Show More]