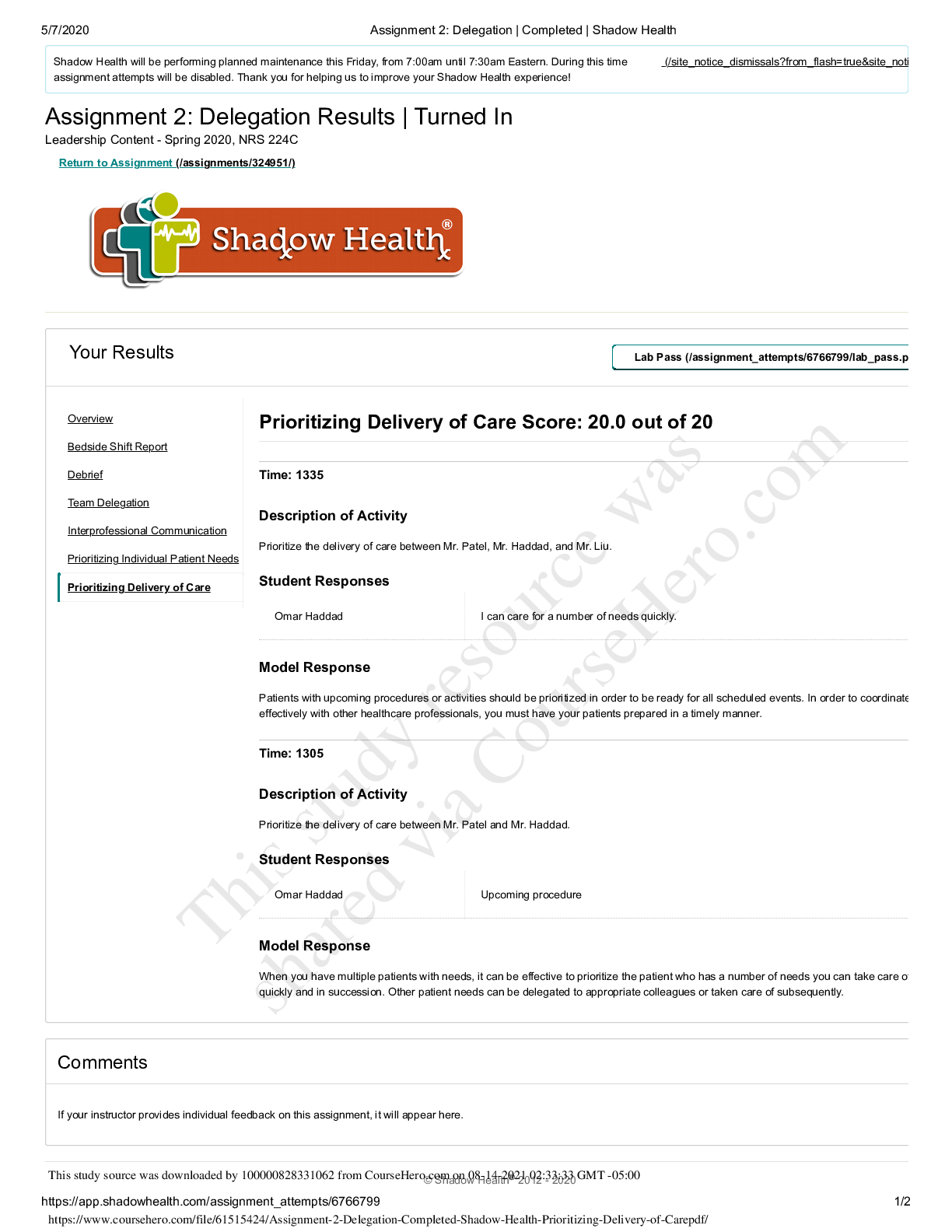

Assignment 2 Delegation Completed Shadow Health Prioritizing Delivery of Care.LATEST 2021/2022

Engineering > QUESTIONS & ANSWERS > Solutions Manual: Ch04-Assembly Lines-s _ Work Systems and Operations Management_Review Questions. (All)

Solutions Manual: Ch04-Assembly Lines-s Review Questions 4.1 What is a manual assembly line? Answer: A manual assembly line is a work system consisting of multiple workers who are organized to pro ... duce a single product or a limited range of products for which demand is high. The assembly workers perform various tasks at workstations that are physically located along the line-of-flow of the product as it is being made. 4.2 What are the factors that favor the use of manual assembly lines? Answer: Factors favoring the use of manual assembly lines include the following: (1) Demand for the product is high or medium. (2) The products made on the line are identical or similar. (3) The total work required to assemble the product can be divided into small work elements. and (4) It is technologically impossible or economically infeasible to automate the assembly operations. 4.3 What are the reasons why manual assembly lines are so productive compared to alternative methods of assembly? Answer: The reasons given in the text are: (1) Specialization of labor, which asserts that when a large job is divided into small tasks and each task is assigned to one worker, the worker becomes highly proficient at performing the single task. (2) Interchangeable parts, which means that each component is manufactured to sufficiently close tolerances that any part of a certain type can be selected at random for assembly with its mating component. (3) Work flow, which means that each work unit should flow steadily along the line and travel minimum distances between stations. (4) Line pacing, in which workers on an assembly line are required to complete their assigned tasks on each product unit within a certain cycle time, which paces the line to maintain a specified production rate. 4.4 What does the term manning level mean in the context of a manual assembly line? Answer: Manning level refers to the number of workers assigned to a workstation. When the term is allied to a given workstation, it is the number of workers at that station. When applied to the entire line, it is the average number of workers per station. 4.5 What are utility workers on a manual assembly line? Answer: Utility workers are workers who are assigned to the line but not to specific workstations; instead they are responsible for functions such as (1) helping workers who fall behind, (2) relieving workers for personal breaks, and (3) maintenance and repair duties. 4.6 What is starving on a manual assembly line? Answer: Starving occurs when an assembly operator has completed his or her assigned task on the current work unit, but the next unit has not yet arrived at the station. The worker is thus starved for work. 4.7 What is blocking on a manual assembly line? . 1Solutions Manual: Ch04-Assembly Lines-s Answer: Blocking means that the operator has completed the assigned task on the current work unit but cannot pass the unit to the downstream station because that worker is not yet ready to receive it. The operator is therefore blocked from working. 4.8 What are the three major categories of work transport in mechanized production lines? Answer: The three major categories are (1) continuous transport, in which the work units move along the line at a constant velocity, (2) synchronous transport, in which the movement of work units is intermittent (stop-and-go) and all work units are moved at the same moment, and (3) asynchronous transport, in which the movement of work units is intermittent but the movements are independent of each other. 4.9 What are the two types of line that can be designed to cope with product variety? What is the difference between them? Answer: The two types are (1) batch model lines, in which the products are produced in batches and line changeover time is required between batches, and (2) mixed model lines, in which different models are made on the same line by workstations that are designed to cope with the model variations, so no downtime between models is experienced. 4.10 What does work content time mean? Answer: The work content time is the sum of the times of all work elements that must be performed to make one unit of the product. It represents the total amount of work that is accomplished by the assembly line on one product unit. 4.11 What are repositioning losses as they are explained in the text? Answer: Repositioning losses on a production line occur because some time is required each cycle to reposition the worker, or the work unit, or both. 4.12 What is the line balancing problem in the design of a manual assembly line? Answer: The line balancing problem is the problem of allocating work elements to workers on the line so that all workers have an equal workload and production cycle time requirements of the line are met. 4.13 What is a minimum rational work element in the context of manual assembly lines? Answer: A minimum rational work element is a work element that has a specific limited objective, such as adding a component to the base part, joining two components, or performing some other small portion of the total work content. It cannot be subdivided without loss of practicality. 4.14 What is a precedence constraint in the context of manual assembly lines? Answer: Precedence constraints are technological requirements of the assembly work elements that limit the sequence in which they can be performed. 4.15 What are the three types of efficiency that must be considered in designing and operating a manual assembly line? Answer: The three types of efficiency are (1) line efficiency, or proportion uptime of the line, (2) repositioning efficiency due to lost time each cycle in repositioning the work unit . 2Solutions Manual: Ch04-Assembly Lines-s or the worker or both, and (3) balance efficiency, which results from the inability to perfectly balance the station workloads on the line. 4.16 What does tolerance time mean? Answer: Tolerance time is the amount of time a work unit spends inside the boundaries of the workstation. It is the length of the station divided by the conveyor velocity. 4.17 Name the three line balancing algorithms described in the text. Answer: The three line balancing algorithms described in the text are (1) largest candidate rule, (2) Kilbridge and Wester method, and (3) ranked positional weights method. 4.18 What are some of the methods by which assembly line balancing efficiency can be improved that are outside the scope of the line balancing algorithms? Answer: The methods indicated in the text include (1) methods analysis on some of the tasks, (2) utility workers to relieve congestion at overloaded stations, (3) preassembly of components, (4) storage buffers between stations, and (5) parallel workstations. Problems Manual Assembly Lines 4.1 Determine (a) the required hourly production rate and (b) the cycle time for a manual assembly line that will be used to produce a product with a work content time of 75 min and an annual demand of 150,000 units, if the plant operates 50 wk/yr, 5 days/wk, and 8 hr/day. It is anticipated that the line efficiency will be 94%. Solution: (a) Rp = 150,000/2,000 = 75 units/hr (b) Tc = 60(0.94)/75 = 0.752 min 4.2 A manual assembly line has 25 workstations and the manning level is 1.0. The work content time to assemble the product is 29.5 min. Production rate of the line is 40 units/hr. The proportion uptime is 96% and the repositioning time is 9 sec. Determine the balance delay on the line. Solution: Tc = 60(0.96)/40 = 1.44 min Ts = 1.44 – 0.15 = 1.29 min Eb = 29.5/25(1.29) = 0.915, d = 1 – 0.915 = 0.085 = 8.5% 4.3 A manual assembly line is being planned for an assembled product whose work content time = 47.2 min. The line will be operated 2000 hr/yr. The annual demand anticipated for the product is 100,000 units. Based on previous assembly lines used by the company, the proportion of uptime on the line is expected to be 94%, the line balancing efficiency will be 92%, and the repositioning time lost each cycle will be 6 sec. The line will be designed with 1 worker/station. Determine (a) the required hourly production rate of the line, (b) the cycle time, (c) the ideal minimum number of workers required, and (d) the actual number of workers required based on the efficiencies given. Solution: (a) Rp = 100,000/2,000 = 50 units/hr (b) Tc = 60(0.94)/50 = 1.128 min . 3Solutions Manual: Ch04-Assembly Lines-s (c) w* = Min Int 47.2/1.128 = 41.84 rounded up to 42 workers (d) Ts = 1.128 – 0.10 = 1.028 min w = Min Int 47.2/1.028(0.92) = 49.9 rounded up to 50 workers 4.4 A manual assembly line is being planned for an assembled product whose annual demand is expected to be 175,000 units/yr. The line will be operated two shifts (4000 hr/yr). Work content time of the product is 53.7 min. For planning purposes, the following line parameter values will be used: uptime efficiency = 96%, balancing efficiency = 94%, and repositioning time = 8 sec. Determine (a) the required hourly production rate of the line, (b) the cycle time, and (c) the ideal minimum number of workers required, and (d) the actual number of workers required based on the efficiencies given. Solution: (a) Rp = 175,000/4,000 = 43.75 units/hr (b) Tc = 60(0.96)/43.75 = 1.3166 min (c) w* = Min Int 53.7/1.3166 = 40.79 rounded up to 41 workers (d) Ts = 1.3166 – 0.1333 = 1.1832 min w = Min Int 53.7/1.1832(0.94) = 48.3 rounded up to 49 workers 4.5 The required production rate for a certain product is 45 units/hr. Its work content time is 71.5 min. The production line for this product includes 5 automated workstations. Because the automated stations are not entirely reliable, the overall line efficiency is expected to be only 88%. All of the other stations will have one worker each. It is anticipated that 6% of each cycle will be lost due to worker repositioning. Balance delay is expected to be 7%. Determine (a) cycle time, (b) number of workers, (c) number of workstations, (d) average manning level on the line, including the automated stations, and (e) labor efficiency on the line. Solution: (a) Tc = 60(0.88)/45 = 1.1733 min (b) Tr = 0.06Tc, therefore, Ts = 0.94Tc and Er = 0.94 Eb = 1 – d = 1 – 0.07 = 0.93 w = Min Int 71.5/1.1733(0.94)(0.93) = 69.7 rounded up to 70 workers (c) n = 70 + 5 = 75 workstations (d) M = 70/75 = 0.933 (e) Labor efficiency = EErEb = (0.88)(0.94)(0.93) = 0.769 = 76.9% 4.6 A manual assembly line is being designed for a product whose annual demand is 100,000 units. The line will operate 50 wk/yr, 5 shifts/wk, and 8 hr/shift. Work units will be attached to a continuously moving conveyor. Work content time is 42.0 min. Assume line efficiency is 0.95, balancing efficiency is 0.93 or slightly less, repositioning time is 6 sec, and manning level is 1.4. Determine (a) average hourly production rate to meet demand and (b) number of workers required. (c) If each station on the line is 3 m long, what is the total length of the assembly line? Solution: (a) Rp = 100,000/50(5)(8) = 100,000/2,000 = 50 units/hr . 4Solutions Manual: Ch04-Assembly Lines-s [Show More]

Last updated: 2 years ago

Preview 1 out of 15 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Can't find what you want? Try our AI powered Search

Connected school, study & course

About the document

Uploaded On

Jan 13, 2023

Number of pages

15

Written in

All

This document has been written for:

Uploaded

Jan 13, 2023

Downloads

0

Views

56

Scholarfriends.com Online Platform by Browsegrades Inc. 651N South Broad St, Middletown DE. United States.

We're available through e-mail, Twitter, Facebook, and live chat.

FAQ

Questions? Leave a message!

Copyright © Scholarfriends · High quality services·