1.

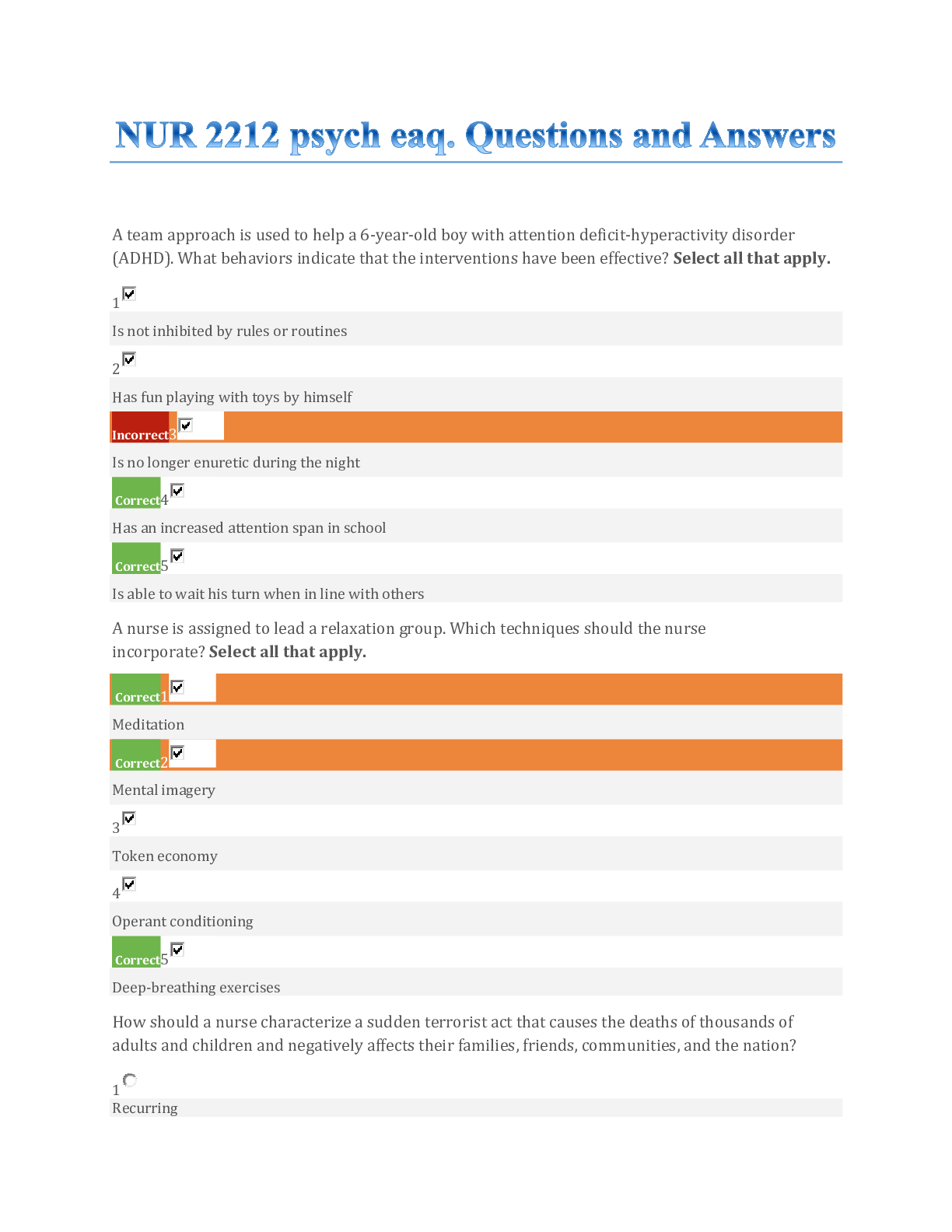

The Cause and Effect diagram can be used to

Identify the causes for improving productivity.

o select

o Identify the causes for improving productivity.

o Describe the relationship between various causes of a probl

...

1.

The Cause and Effect diagram can be used to

Identify the causes for improving productivity.

o select

o Identify the causes for improving productivity.

o Describe the relationship between various causes of a problem and its effect.

o Improve fit and finish of a product.

o Reduce costs in a process.

o Define Six-Sigma.

• 2.

In the Cause and Effect diagram, the word Category refers to:

A group of similar causes

o select

o The rank ordering of quality issues

o Cost segmentation

o A classification system of problems

o Priority order

o A group of similar causes

• 3.

In the Cause and Effect diagram, Effect refers to:

The problem being analyzed

o select

o Cosmetic quality changes

o A grouping of causes

o The result of quality improvement

o The problem being analyzed

o Pareto analysis

• 4.

The Cause and Effect diagram is also referred to as the "fishbone diagram" because:

The shape of the actual diagram resembles a fishbone.

o select

o It is named after its inventor.

o Fishbone is a quality management practice.

o It is part of the Six-Sigma process.

o The shape of the actual diagram resembles a fishbone.

o It is another term for control chart.

• 5.

Which of the following is an alternate name for the Cause and Effect diagram?

Ishikawa diagram

o select

o Scatter chart

o Ishikawa diagram

o Pareto chart

o Check sheet

o Control chart

• 6.

In the Cause and Effect diagram, the word Cause refers to

A possible factor causing a particular quality problem

o select

o Supporting arguments for quality improvement

o Improvement in quality

o The result of quality issues

o A movement to improve quality

o A possible factor causing a particular quality problem

2.

A production process consists of a three-step operation. The scrap rate is 10 percent for the first step and 6 percent

for the other two steps.

a. If the desired daily output is 450 units, how many units must be started to allow for loss due to scrap? (Do not

round intermediate calculations. Round up your final answer to the next whole number.)

b. If the scrap rate for each step could be cut in half at every operation, how many units would this save in terms of

the scrap allowance? (Do not round intermediate calculations. Round up your final answer to the next

whole number.)

c. If the scrap represents a cost of $10 per unit, how much is it costing the company per day for the original scrap

rate (i.e. the Part a scrap rate)? (Round your answer to the nearest whole number. Omit the "$" sign in

your response.)

3. In addition, the assembly foreman, stockroom foreman and quality engineer report to the

manufacturing manager.

Current Inventory Control System

The current inventory control “system” consists of orders for stock replenishment being made by

the stockroom foreman, the purchasing manager, or the manufacturing manager whenever one of

them notices that the inventory is low. An order for replenishment of inventory is also placed

whenever someone (either a customer or an employee in the assembly area) wants an item and it

is not in stock.

Some inventory is needed for the assembly of the high-pressure equipment for the car wash and

industrial applications. There are current and accurate bills of material for these assemblies. The

material needs to support the assembly schedule are generally known well in advance of the

build schedule.

The majority of inventory transactions are for repair parts and for supplies used by the car

washes, such as paper towels, detergent, and wax concentrate. Because of the constant and

rugged use of the car wash equipment, there is a steady demand for the various repair parts.

The stockroom is well organized, with parts stored in locations according to each vendor. The

number of vendors is relatively limited, with each vendor generally supplying many different

parts. For example, the repair parts from Allen Bradley, a manufacturer of electrical motors, are

stocked in the same location. These repair parts will be used to provide service for the many

electrical motors that are part of the high-pressure pump and motor assembly used by all of the

car washes.

Because of the heavy sales volume of repair parts, there are generally two employees working in

the stockroom—a stockroom foreman who reports to the manufacturing manager and an assistant

to the foreman. One of these two employees will handle customer orders. Many customers stop

by and order the parts and supplies they need. Telephone orders are also received and are

shipped by United Parcel Service the same day.

The assembly area has some inventory stored on the shop floor. This inventory consists of lowvalue items that are used every day, such as nuts, bolts, screws, and washers. These purchased

items do not amount to very much dollar volume throughout the year. Unfortunately, oftentimes

the assembly area is out of one of these basic items and this causes a significant amount of

downtime for the assembly lines.

Paperwork is kept to a minimum. A sales slip listing the part numbers and quantities sold to a

customer is generally made out for each sale. If the assembly department needs items that are not

stocked on the assembly floor, someone from that department will enter the stockroom and

withdraw the necessary material. There is no paperwork made out for the items needed on the

assembly floor.

There were 973 different part numbers purchased for stock last year and those purchases

amounted to $314,673. An analysis of inventory records shows that $220,684 was spent on just

179 of the part numbers. Fortunately for Harvey Industries, most of the items they purchase are

stocked by either the manufacturer or by a wholesaler. When it is discovered that the company is

out of stock on an item, it generally takes only two or three days to replenish the stock.

Due to the company’s recent losses, its auditing firm became concerned about the company’s

ability to continue in business. Recently the company sold off excess vacant land adjoining its

manufacturing facility to generate cash to meet its financial obligations.

New president

Because of the recent death of the owner, the trust department of a Milwaukee bank (as trustee

for the state) has taken over the company’s affairs and has appointed a new company president.

The new president has identified many problem areas—one of which is improper inventory

control. He has retained you as a consultant to make specific recommendations concerning a

revised inventory control system. What are your recommendations and their rationale?

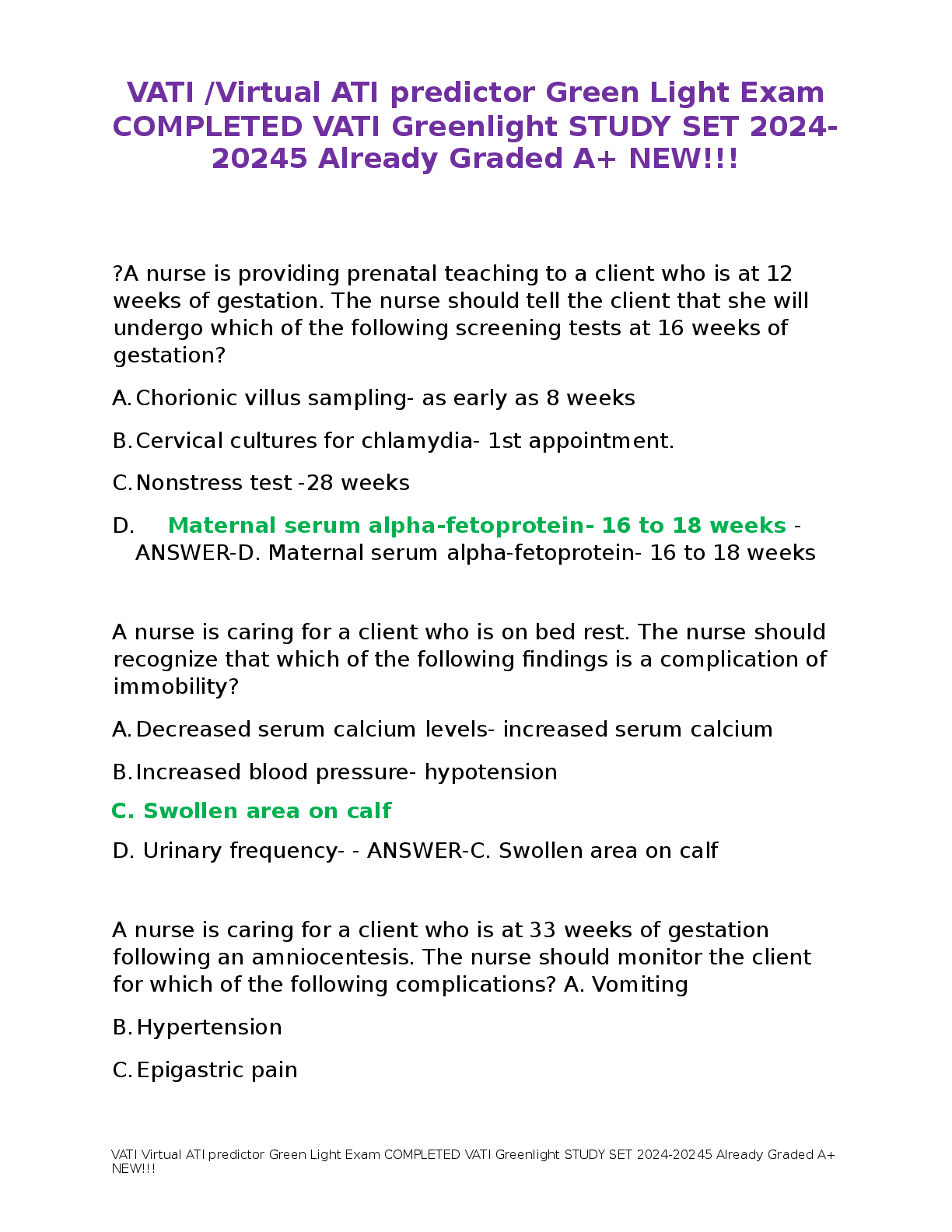

• 1.

For the 179 parts that account for approximately 70% of dollars spent last year on stock,

what inventory accuracy would APICS recommend?

Plus/minus 1%

o select

o Plus/minus 5%

o Plus/minus 0.2%

o Plus/minus 1%

• 2.

The assembly area often has downtime due to stockouts of basic items such as nuts,

bolts, screws, and washers. What do you recommend?

Have the stockroom assistant fill up the bins in the assembly area each morning

o select

o Have the stockroom assistant fill up the bins in the assembly area each morning

o Have all workers go to the main stock room to replenish parts whenever they feel they need

more

o Tell the workers to use less screws and washers when parts are running low

• 3.

Replenishments are currently made when someone notices parts are "low"; what should

"low" be?

Low should be anything below a full container of parts to minimize stockout risk

o select

o Low should be set to zero to minimize space requirements

o Low should be anything below a full container of parts to minimize stockout risk

o Low should be enough stock to maintain the desired order cycle service level

• 4.

How would you recommend reducing shortages?

Use a two-bin system for repair parts and supplies, plus order material required by the build

schedule

o select

o Have the new president order all materials once each week based on customer orders

o Reduce inventories to reduce shortages

o Use a two-bin system for repair parts and supplies, plus order material required by the build

schedule

• 5.

What is one possible explanation for the steadily increasing inventory levels?

High-pressure washer systems are being built to meet a forecast that is higher than actual

demand.

o select

o Sales of repair parts and supplies have unexpectedly increased this past year.

o High-pressure washer systems are being built to meet a forecast that is higher than actual

demand.

o The company had to purchase inventory to make use of the cash generated by the sale of their

excess land.

• 6.

What level of safety stock should the company target for repair parts?

The same level as "C" item components

o select

o As high of a level as required to satisfy customer service contracts

o The same level as "C" item components

o No safety stock, because that indicates poor planning

• 7.

Office supplies come from one supplier with deliveries once per week. Which type of

inventory model should be used to help decide how much to order?

Economic Order Quantity Models

• 4. The A-B-C approach typically classifies inventory items according to:

The First In First Out rule

o select

o The warehouse space available

o The First In First Out rule

o The physical size of items

o The annual dollar value

o The relative quantity

• 2.

The “annual dollar value” used in the A-B-C approach refers to:

Storage cost of inventory multiplied by average annual inventory

o select

o Price of the inventory item multiplied by average annual inventory

o Dollar value per unit multiplied by annual usage rate

o Storage cost of inventory multiplied by average annual inventory

o Production plan cost

o Price of the final product multiplied by year-end inventory

• 3.

Items classified as “A” using the A-B-C approach generally account for about:

Top 15% of items according to annual dollar value

o select

o Top 5% of items according to annual dollar value

o Top 50% of items according to annual dollar value

o Top 35% of items according to annual dollar value

o Bottom 50% of items according to annual dollar value

o Top 15% of items according to annual dollar value

• 4.

Items classified as “B” using the A-B-C approach generally account for about:

Top 35% of items according to annual dollar value

o select

o Bottom 50% of items according to annual dollar value

o Middle 35% of items according to annual dollar value

o Middle 50% of items according to annual dollar value

o Middle 15% of items according to annual dollar value

o Top 35% of items according to annual dollar value

• 5.

Items classified as “C” using the A-B-C approach generally account for about:

Bottom 35% of items according to annual dollar value

o select

o Bottom 50% of items according to annual dollar value

o Top 50% of items according to annual dollar value

o Bottom 35% of items according to annual dollar value

o Middle 35% of items according to annual dollar value

o Bottom 15% of items according to annual dollar value

• 6.

The main reason for classifying inventory is:

Rough cut capacity planning

• 5. 1.

Which of the following is taken into account in forecasting sales?

Competitor's history, industry trends, economic forecast

o select

o Competitor's history, fashion trends, weather forecast

o Company history, industry trends, weather forecast

o Company history, industry trends, economic forecast

o Company industry, fashion trends, economic forecast

o Competitor's history, industry trends, economic forecast

o Company history, weather forecast, economic forecast

• 2.

In addition to historical data, which other factor is taken into account when forecasting

sales?

Pop culture trends

o select

o Pop culture trends

o Analysis of customer returns

o Market research

o Population growth

o Climate trends

o Customer surveys

• 3.

How is warehouse travel minimized?

By the location selected for the fast and slow moving products

o select

o By automating their conveyors

o By the location selected for the fast and slow moving products

o By locating the product randomly in the warehouse

o By locating only the fast movers near the receiving docks

o By organizing the order pickers in two person teams

o By eliminating the use of conveyors

• 4.

How are order pickers routed efficiently?

In a serpentine pattern

o select

o They are randomly routed

o None of these

o In a right to left pattern

o In two person teams

o In a left to right pattern

o In a serpentine pattern

• 5.

When is the inventory count for an item reduced?

When the customer enters their order

o select

o When the order is filled

o When the customer's credit is approved

o When the customer receives the order

o When the customer enters their order

o When the order is shipped

o When the customer pays for the order

• 6.

Which of the following is the key to the success of BuyCostumes.com?

Operations planning

• 1.

Which priority rule processes jobs in the order in which they arrive at a work center?

FCFS

o select

o S/O

o SPT

o FCFS

o EDD

o CR

• 2.

Which performance measure describes the total time needed to complete a group of jobs?

Makespan

o select

o First come, first served

o Job flow time

o Average number of jobs

o Job lateness

o Makespan

• 3.

A job has a flow time of 14, takes 3 days to process, and is due on day 11. How tardy will it

be?

3 days

o select

o 11 days

o 2 days

o 3 days

o 1 day

o 14 days

• 4.

A job is due on day 1 and has 3 days of processing left. It is currently day 4. What is the

critical ratio?

-1

o select

o 3

o -1

o 4

o .75

o 6

• 5.

A job is due on day 20 and has 4 remaining operations with 8 days of processing left.

What is the slack per operation?

12

o select

o 4

o 3

o 12

o 2

o 8

• 6.

Which priority rule results in the lowest average completion time?

SPT

The times required to complete each of eight jobs in a two-machine flow shop are shown in the table that follows.

Each job must follow the same sequence, beginning with machine A and moving to machine B.

a. Determine a sequence that will minimize makespan time.

The sequence is

b-a-c-d-e-f-g-h

.

b. Find machine B’s idle time.

Idle time 18

hrs

c. For the sequence determined in part a, how much would machine B's idle time be reduced by splitting the last

two jobs in half?

New idle time

11

hrs, savings of

7

hrs.

• New product development is the mechanism for which of the following?

Improving market share and financial performance

o select

o Adding new projects

o Increasing sales and customer satisfaction

o Finishing projects on time and on budget

o Expanding the business

o Offering more options for the customer

o Improving market share and financial performance

• 2.

What are the critical resources of a project?

Materials, methods, and money

o select

o Raw materials, equipment, money, and time

o Materials, methods, and money

o People, money, and time

o People and time

o Time and money

o Raw materials, equipment, people, money, and time

• 3.

3. What is a Statement of Work (SOW)?

A comprehensive project plan for completing all the necessary project work

o select

o A tool for managing performance

o An authorization to assign a project manager

o A method for communicating new products

o A tool for measuring project productivity

o A comprehensive project plan for completing all the necessary project work

o An authorization to spend money

• 4.

What is the key tool for managing the logistics of the project?

Control Chart

o select

o Critical Path Method

o Control Chart

o Gantt Chart

o Statement of Work

o Work Breakdown Structure

o Work Package

• 5.

Why do project managers utilize the Critical Path Method (CPM)?

To ensure on time and on budget project completion

o select

o To improve productivity

o To ensure on time and on budget project completion

o To save time

o To provide a communication method

o To hold people accountable

o To measure their performance

• 6.

Which combination of elements will ensure success for any size project?

Careful planning, well defined milestones, teamwork, and flexibility

o select

o Careful planning and teamwork

o A qualified project manager and teamwork

o A qualified project manager, flexibility, and teamwork

o Careful planning, well defined milestones, teamwork, and flexibility

o Sufficient time and budget

o A qualified project manager, sufficient time and budget

For each of the problems listed, determine the following quantities for each activity: the earliest start

time, latest start time, earliest finish time, latest finish time, and slack time. List the critical activities,

and determine the expected duration of the project.

a.

[Show More]