Chemistry > QUESTIONS & ANSWERS > McMaster University - CHEM ENG 4X03ChE 4X3 Assignment 5 2020 soln (Highly rated) (All)

McMaster University - CHEM ENG 4X03ChE 4X3 Assignment 5 2020 soln (Highly rated)

Document Content and Description Below

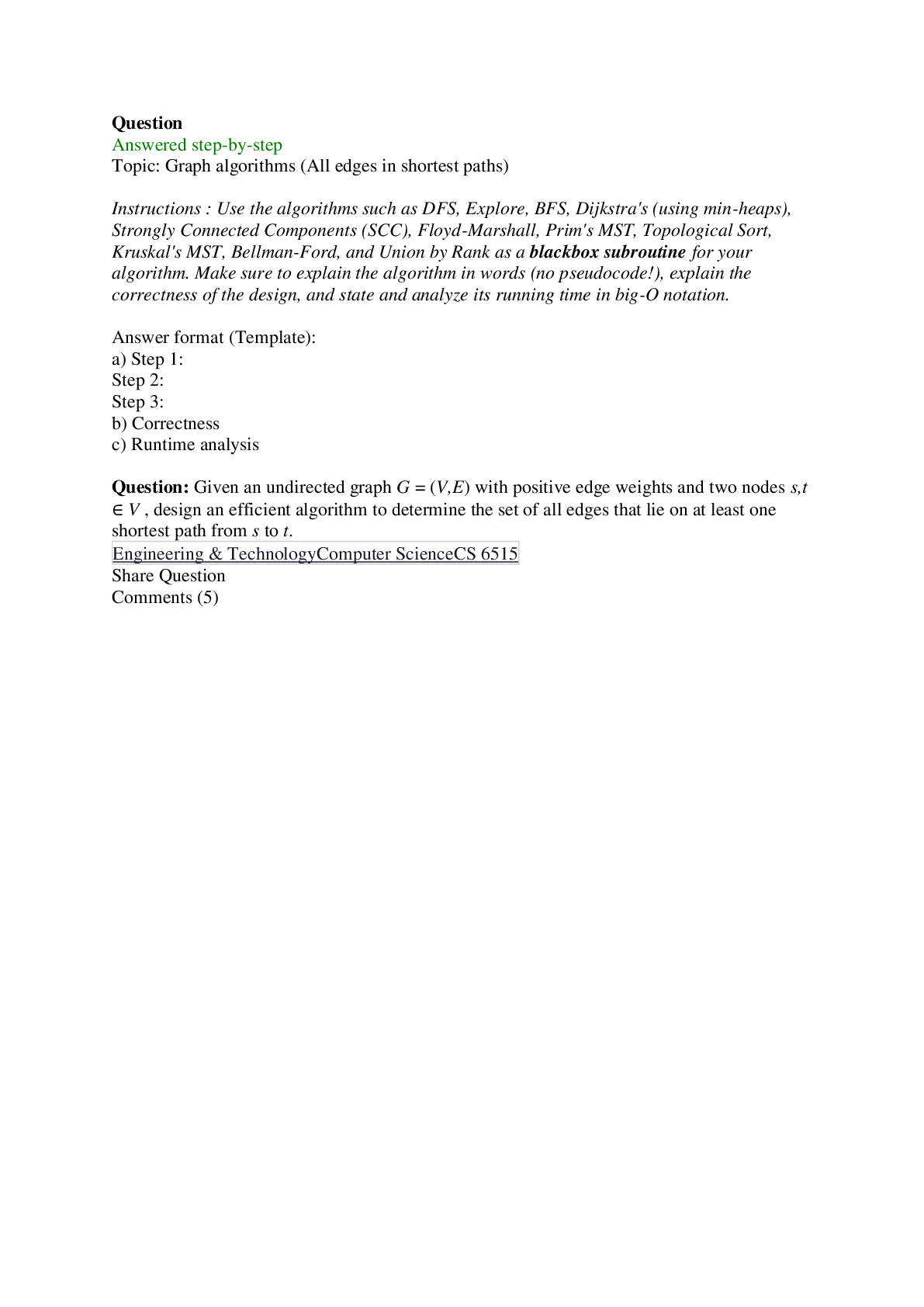

Assignment #5 ChE 4X03/6X03 Introduction to Polymer Processing Due Tuesday April 7 1. [15 Marks] An extrusion line has been set up to prepare two planks at the same time. The line extrudes a wood ... composite (WC) resin which has a measured melt index of I2.16kg = 0.8 g/10min and I10kg = 6 g/10min at 180oC. Melt density of WC at this temperature is 1190 kg/m3. The measurement was determined under the standard conditions of ASTM D-1238 [Lc = 8.000 mm (capillary length); Dc = 2.0955 mm (capillary diameter); Dp = 9.5504 mm (plunger diameter)]. We are only concerned about the 250 mm, 15 L/D melt extruder (i.e. Db = 250mm with no solids conveying zone or melting zone) being used in the line, which has a 12mm deep constant depth square-pitched metering screw (flight thickness, e = 25 mm) rotating at 60 RPM. The die splits the flow to produce two planks of equal cross-section, 18 cm wide and 5 cm high, and is drawn in the figure below. The internal length of the die (i.e. length of the flow path in the die) is L = 75 cm. a. Determine the output rate (m3/s) if the pressure rise along the screw is 2.961 MPa. [10 Marks] b. Determine how closely the two opening in the die can be placed, i.e. distance S, if the polymer has a known first normal stress difference, ?! = 30 ∙ ?"!.$%[units MPa] (use the Tanner equation to solve). [5 marks 2. [15 Marks] Determine the diameter of runner B which is attached between sprue A to mold M1, seen in the figure below (also showing the clamping force direction for the system as a big arrow). Both runners B and C are 10 cm long (ignore the bend in runners B and C for the calculations). Two molded sheets are made at the same time, each with 5 mm thick and 15 cm wide (into the plane of the paper) but the sheet in mold M1 was 8 cm long while the sheet in mold M2 was 12 cm long. The differences in length for the molded sheets can be seen in the figure below. The PET resin has a viscosity of η = 12,770*γ-0.48. The elapsed time for each mold to fill from the time the liquid starts to enter the mold cavities was 9 seconds; runners are not included in this fill time. The clamping force was equal to the packing pressure, which was 5 times greater than the filling pressure. Determine the clamping force in tonnes (1 tonne=9810 N). Sprue A diameter: 4 mm; length: 4 cm Runner C diameter: 3 mm length: 10 cm 3. [10 Marks] The mold for four (4) cell phone back plates are shown in the attached figure (with only two back plates actually showing and the other two behind). Each cavity is filled in 5 seconds through two secondary runners shown (total of 8 secondary runners in the mold). Each runner has a round cross-section with a 3 mm diameter and is 40 mm long. The packing pressure is 6 times larger than the pressure at the end of filling. Determine in tonnes the clamping force required. The polymer viscosity is defined by power-law parameters, m = 7000 Pa-sn and n = 0.7, and its melt density is 710 kg/m3. The primary runner and sprue feeding the secondary runners have a negligible pressure drop compared to the secondary runners and flow in the mold cavity. 4. [20 Marks] Determine the filling time of each cavity for a mold used for preparing two polyurethane rubber shoe pads (modelled as a slab of 30.48 cm long x 10.16 cm wide x 1.25 cm thick for Cavity C, C’). The necessary clamping force is 750 tonnes to balance a packing pressure that is 3 times the filling pressure. The rubber has a viscosity of η = 3,600*γ-0.5. Pipe dimensions [A: 5mm dia., 8 cm long] [B,B’: 3.5mm dia., 7 cm long]. The direction of the clamping force is out of the page and ignores the presence of the pipes in the projected area calculation. [Show More]

Last updated: 2 years ago

Preview 1 out of 7 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$9.50

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Apr 07, 2021

Number of pages

7

Written in

Additional information

This document has been written for:

Uploaded

Apr 07, 2021

Downloads

0

Views

69