Business > QUESTIONS & ANSWERS > Tarleton State University - ENGT 4336Ch4 Fundamentals-of-production-Control-and-planning-Stephan-N-C (All)

Tarleton State University - ENGT 4336Ch4 Fundamentals-of-production-Control-and-planning-Stephan-N-Chapma (DOWNLOAD TO SCORE A+)

Document Content and Description Below

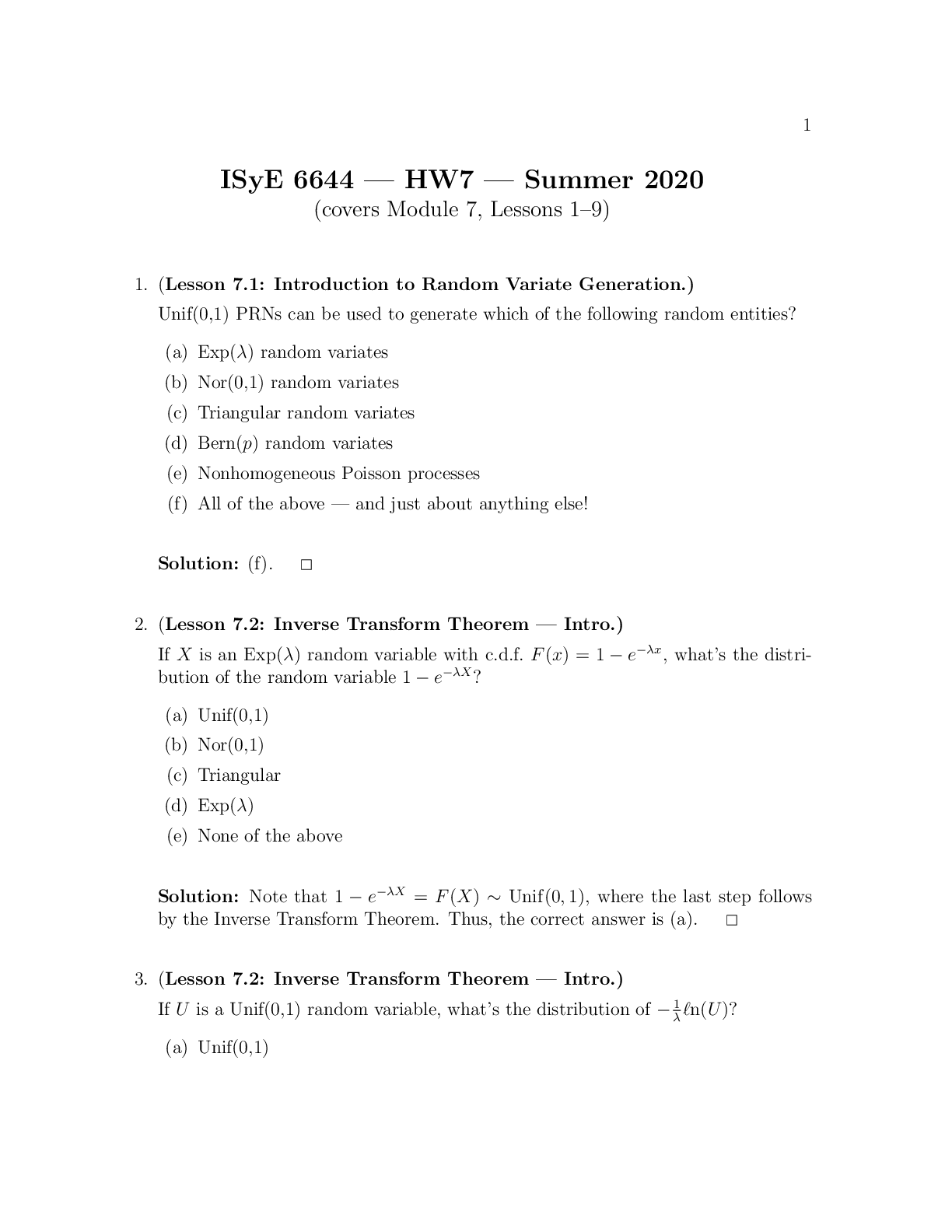

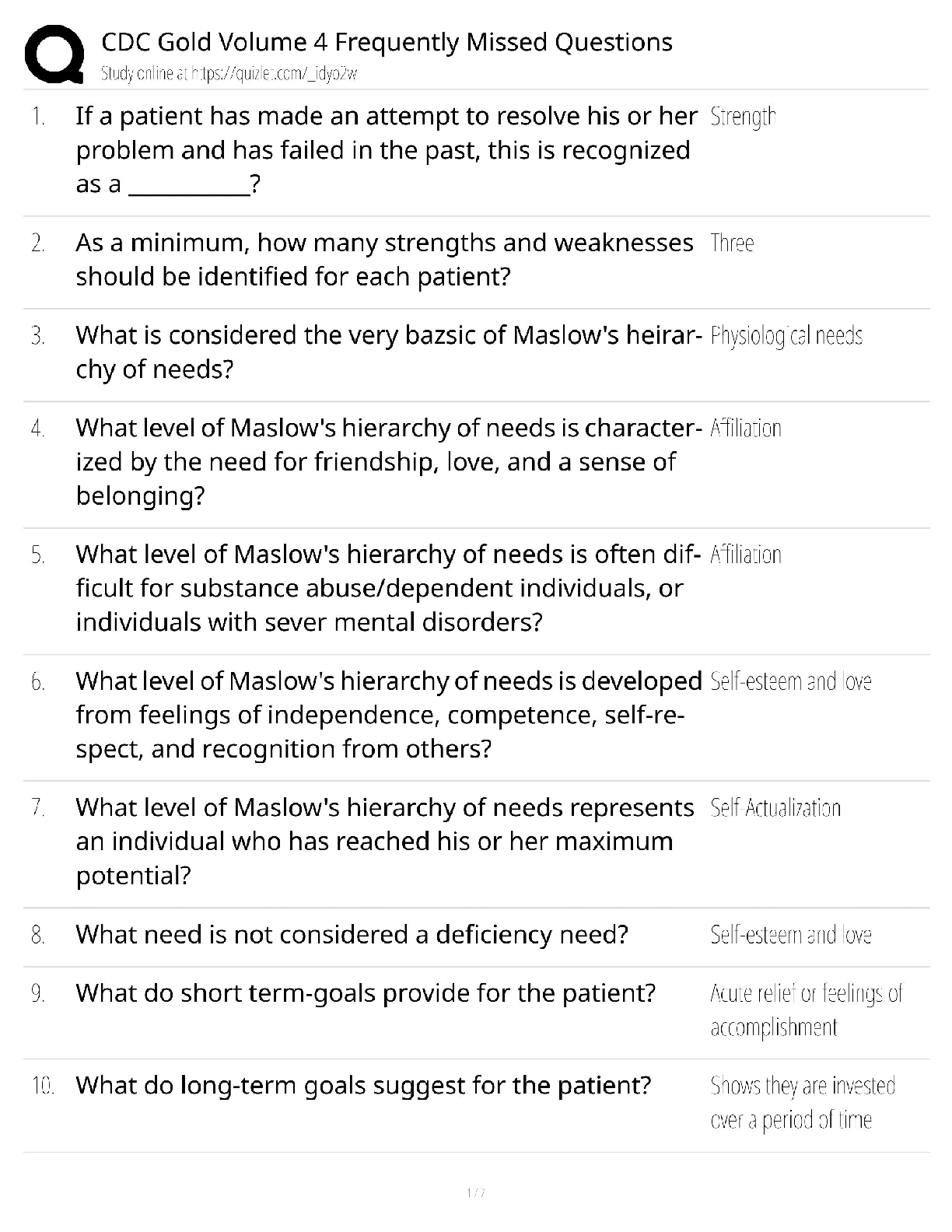

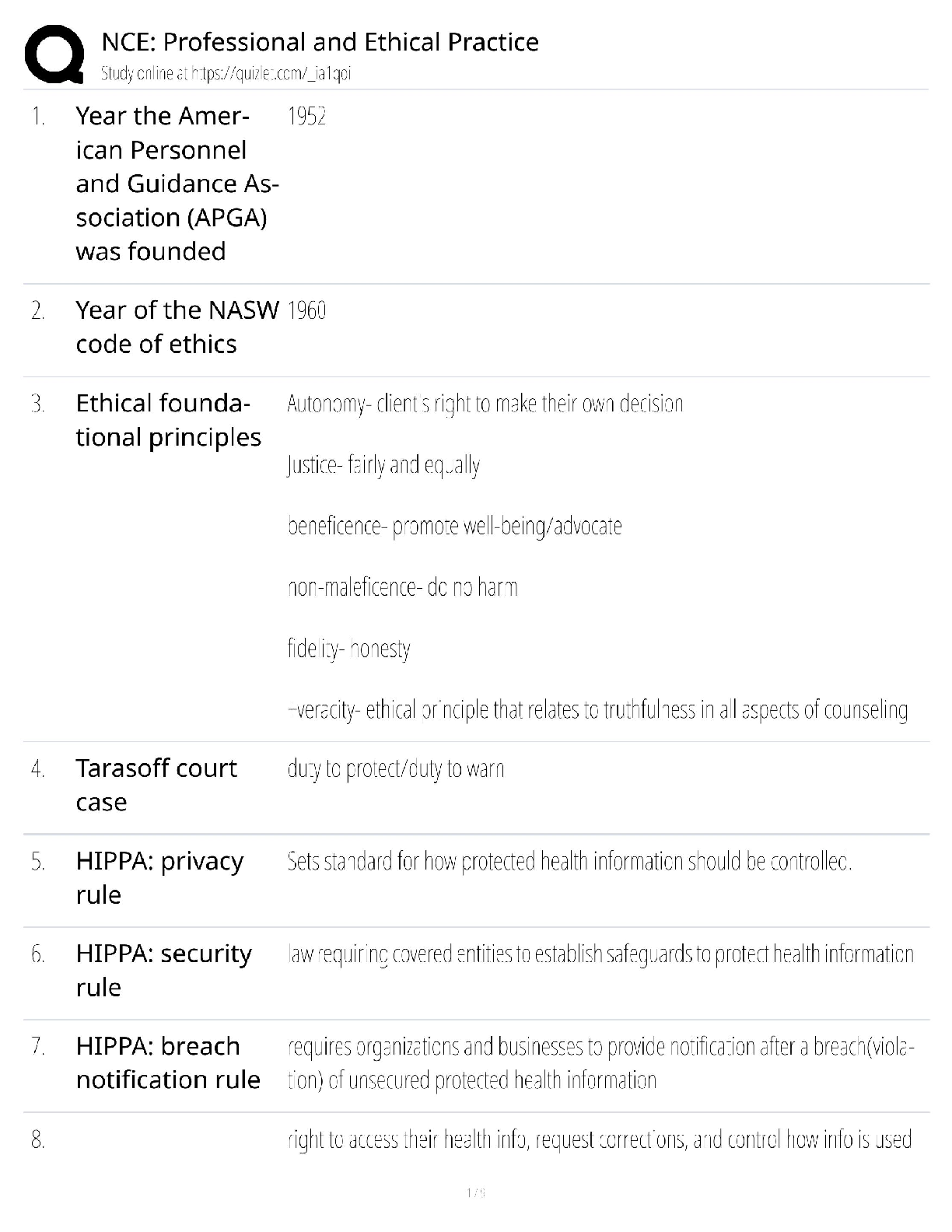

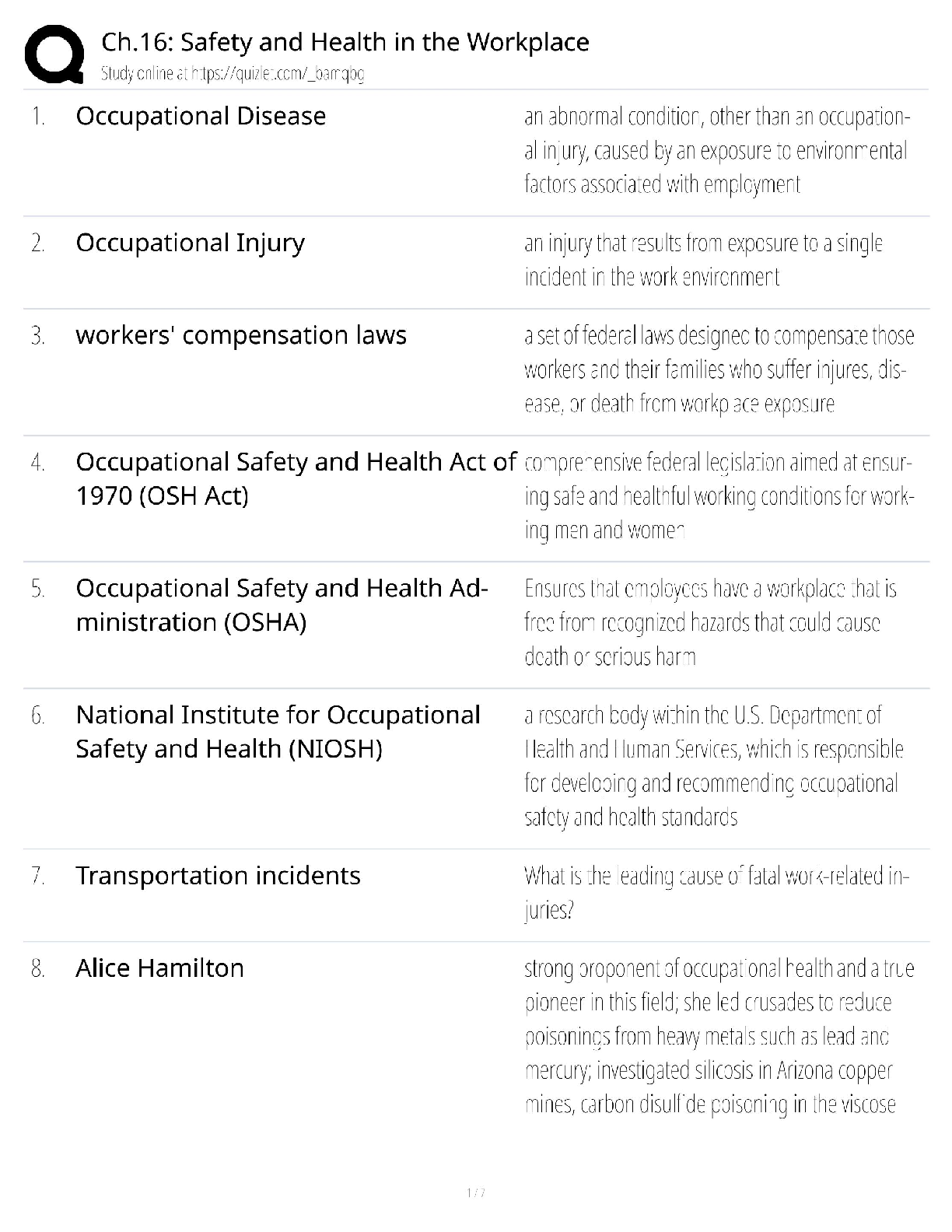

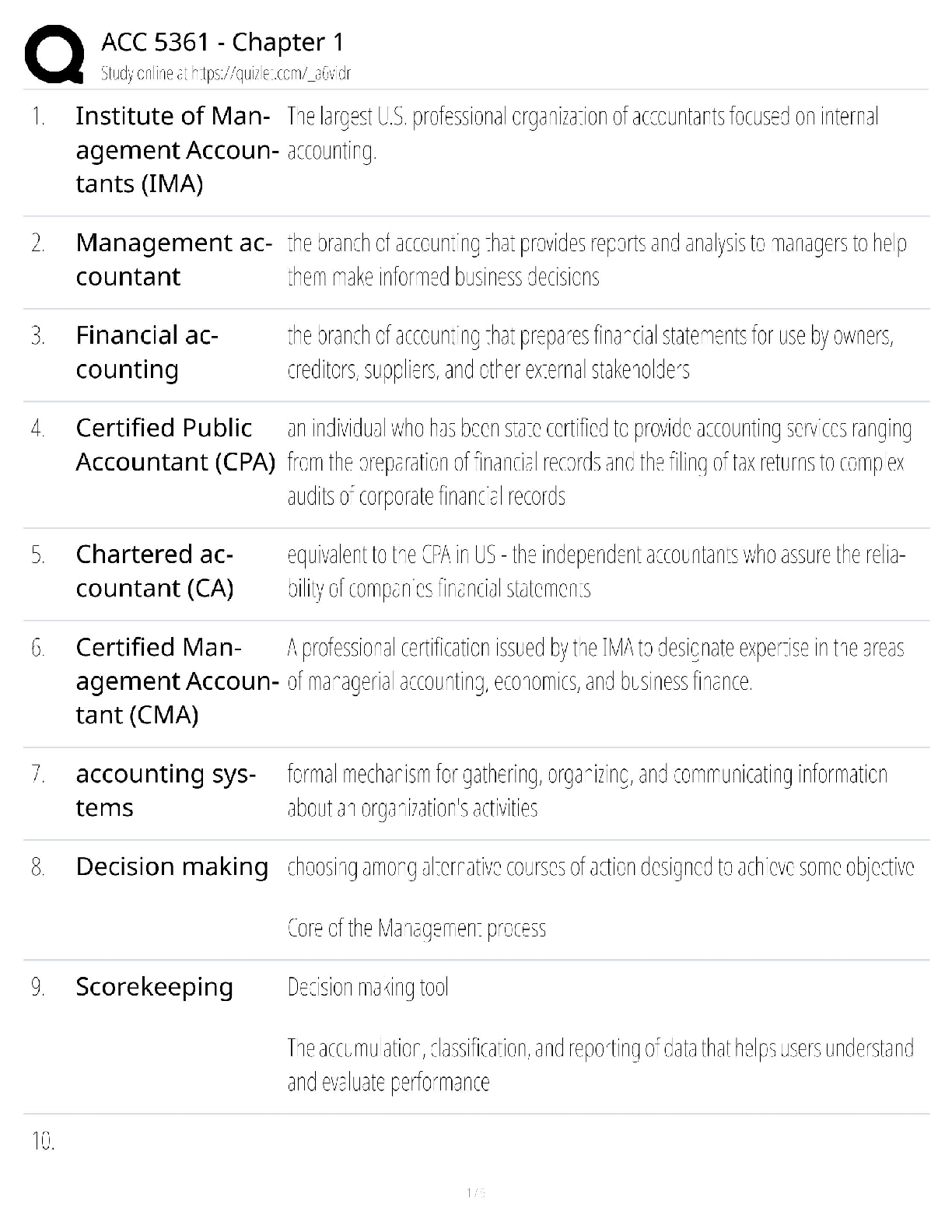

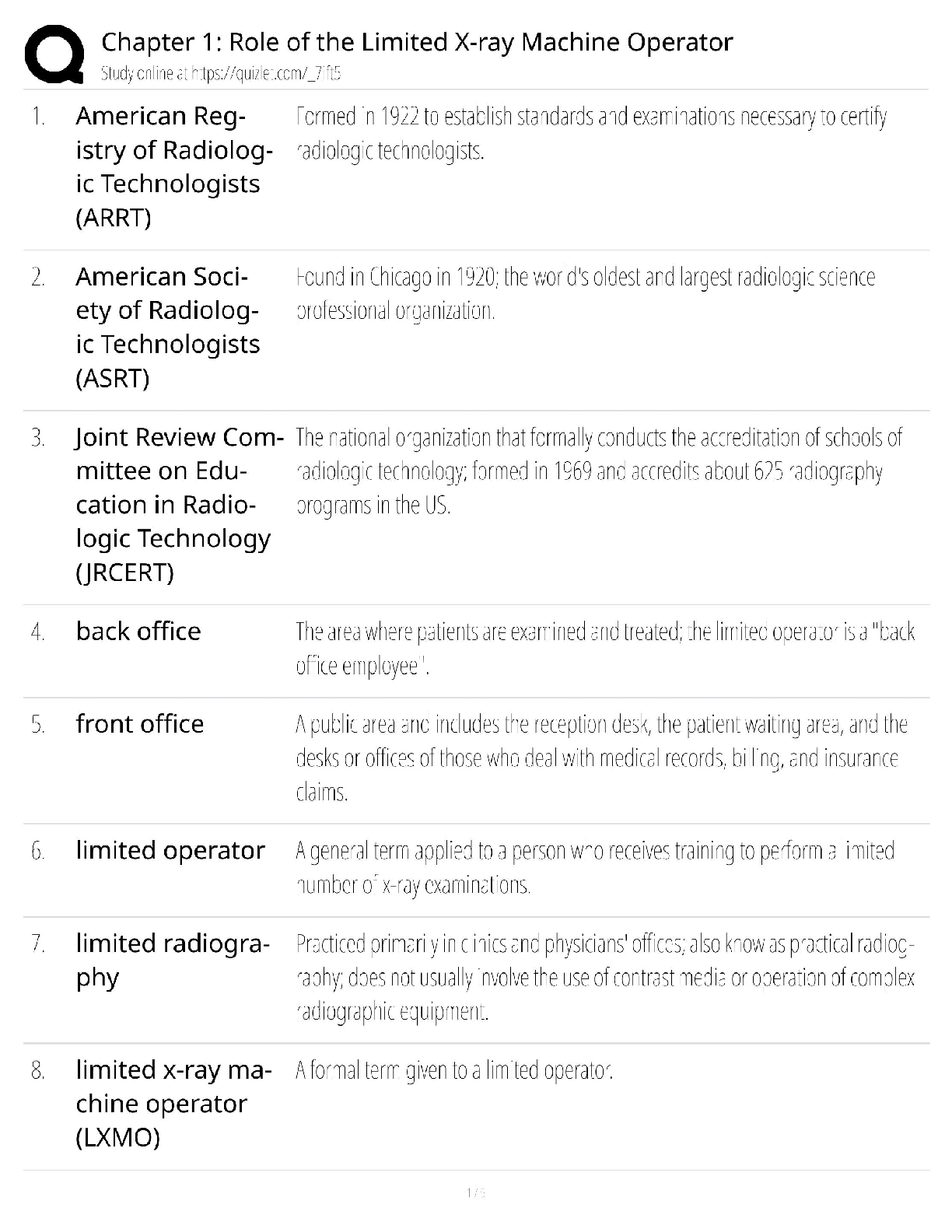

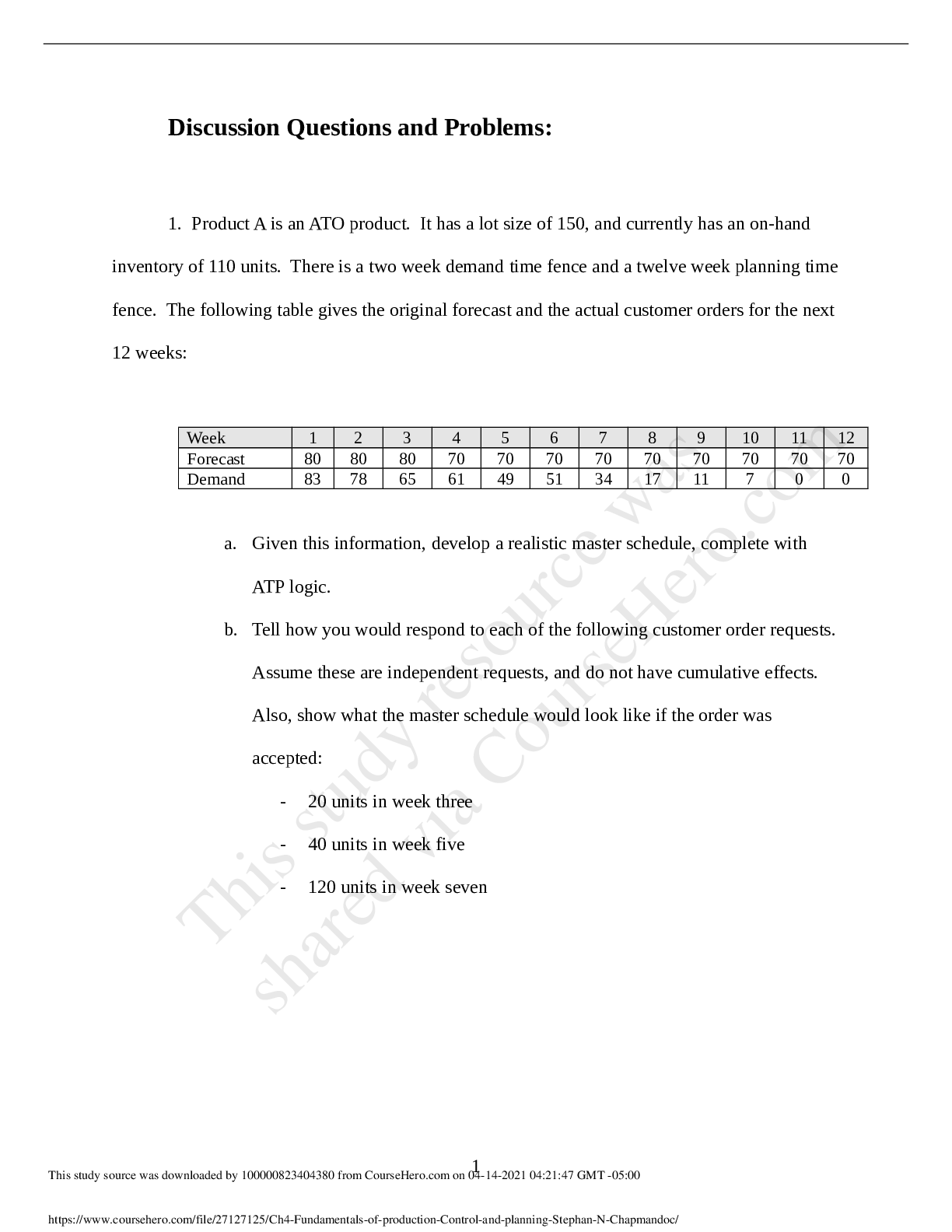

Discussion Questions and Problems: 1. Product A is an ATO product. It has a lot size of 150, and currently has an on-hand inventory of 110 units. There is a two week demand time fence and a twelve w ... eek planning time fence. The following table gives the original forecast and the actual customer orders for the next 12 weeks: Week 1 2 3 4 5 6 7 8 9 10 11 12 Forecast 80 80 80 70 70 70 70 70 70 70 70 70 Demand 83 78 65 61 49 51 34 17 11 7 0 0 a. Given this information, develop a realistic master schedule, complete with ATP logic. b. Tell how you would respond to each of the following customer order requests. Assume these are independent requests, and do not have cumulative effects. Also, show what the master schedule would look like if the order was accepted: - 20 units in week three - 40 units in week five - 120 units in week seven 1 Week 1 2 3 4 5 6 7 8 9 10 11 12 Forecast 80 80 80 70 70 70 70 70 70 70 70 70 Demand 83 78 65 61 49 51 34 17 11 7 0 0 Projected Available 110 27 99 19 99 29 109 39 119 49 129 59 139 Available to Promise 27 7 40 65 122 143 150 MPS 0 150 0 150 0 150 0 150 0 150 0 150 b. 20 units in week three - Can provide from current inventory on hand 40 units in week five - Can provide from week 4 120 units in week seven - Can provide from weeks 1, 2, 4, and 6 2. Suppose that a master scheduler consistently finds that there is inadequate capacity to produce the product the facility needs in order to satisfy customer demand. What actions should they take and why? The company should consider options for additional capacity including overtime, subcontract, hiring additional personnel, extra shifts, etc. 3. How are Sales and Operations Plans and Master Schedules different for pure service operations as opposed to manufacturing? What is (are) the major causes of the differences? The major difference is the source or amount of customer input. The pure service operation is closer to an MTO than any other type of product environment because the customer has a tremendous impact on the product environment (a barber shop for instance). Manufacturing has less of a customer input than in a service industry. 4. Describe in your own words why the minimum time horizon for a master schedule should be longer than the assembly time for the final product. The company needs to be able to plan for the assembly of all components otherwise components won't be available when needed [Show More]

Last updated: 3 years ago

Preview 1 out of 9 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$7.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Apr 14, 2021

Number of pages

9

Written in

All

Additional information

This document has been written for:

Uploaded

Apr 14, 2021

Downloads

0

Views

104