NIH Stroke Scale > QUESTIONS & ANSWERS > ALE BOARD EXAM REVIEWER (All)

ALE BOARD EXAM REVIEWER

Document Content and Description Below

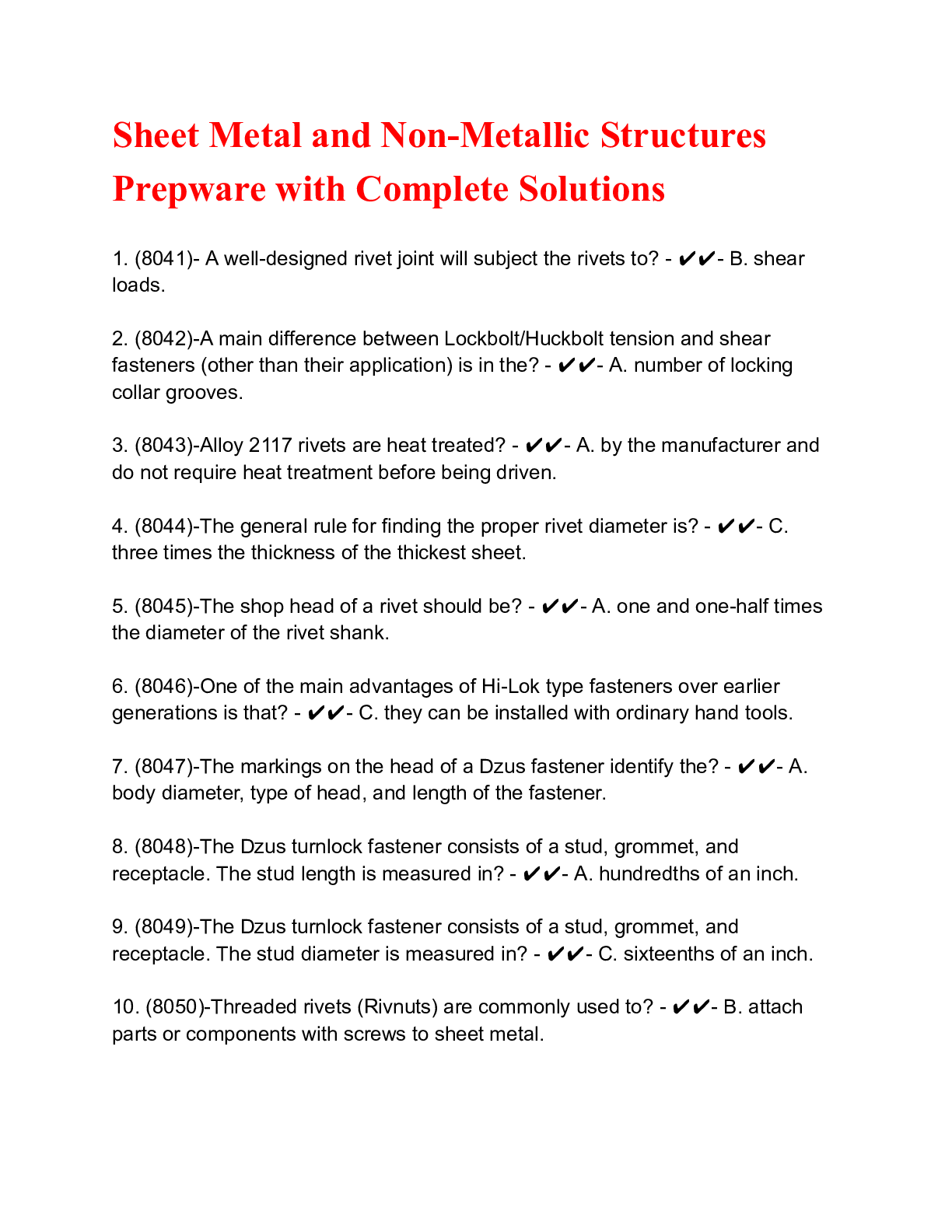

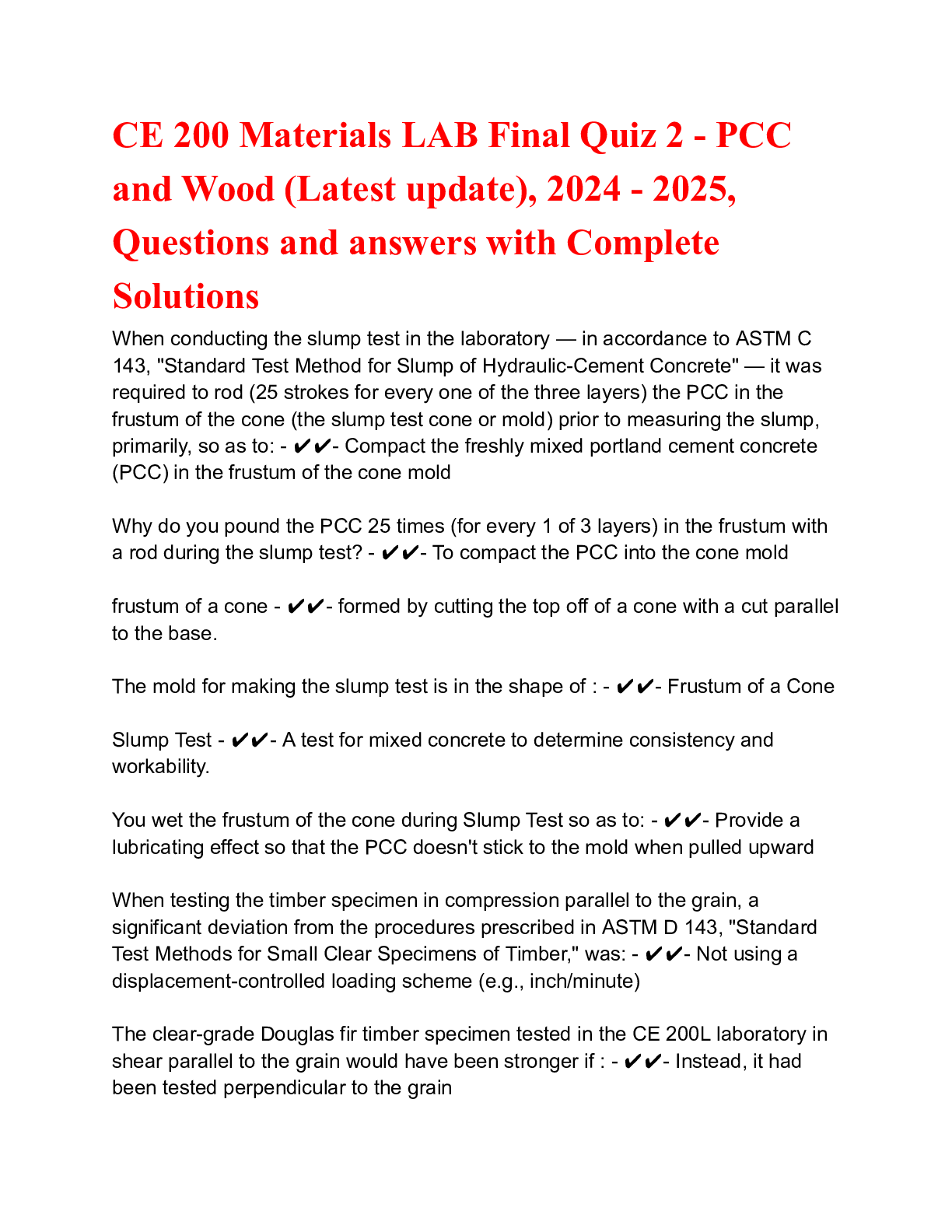

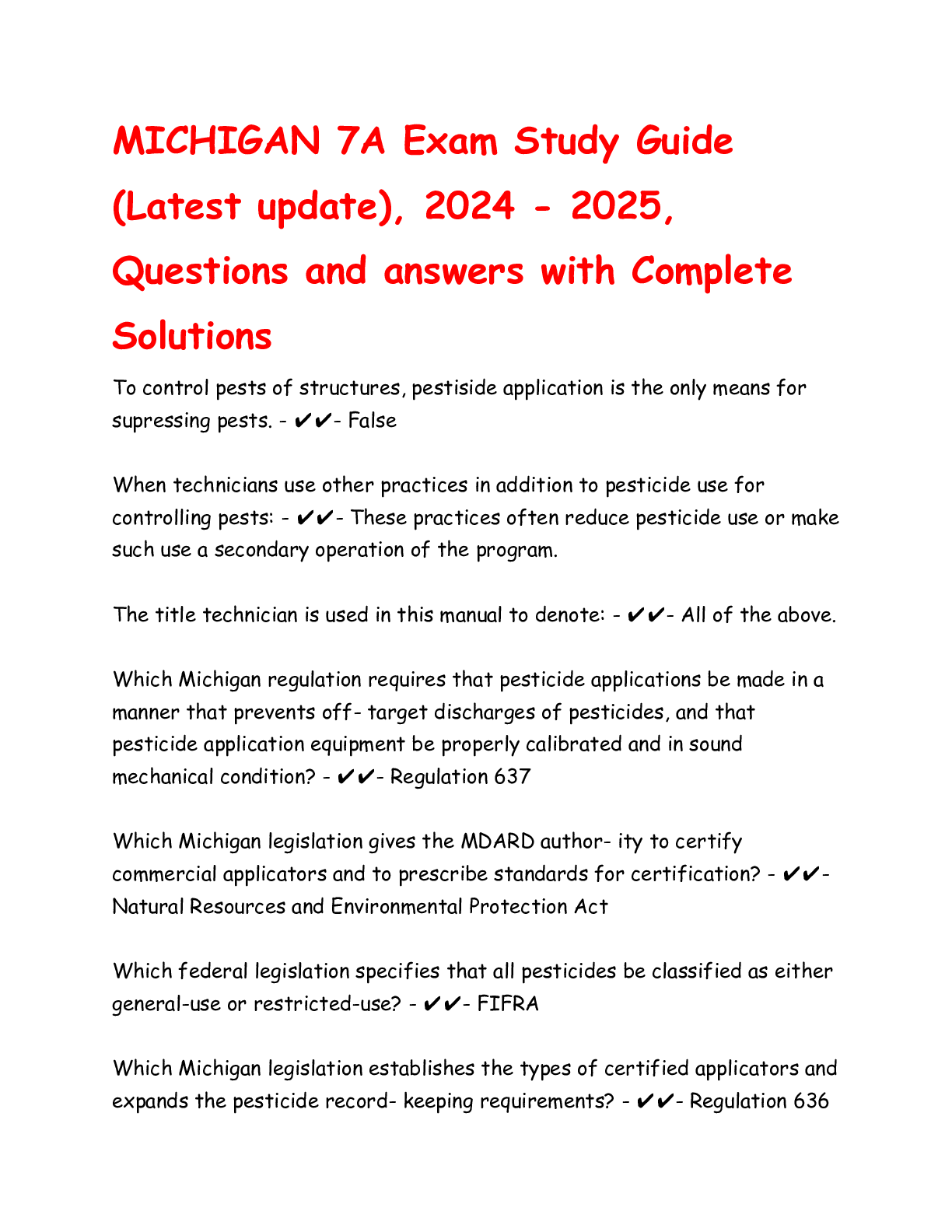

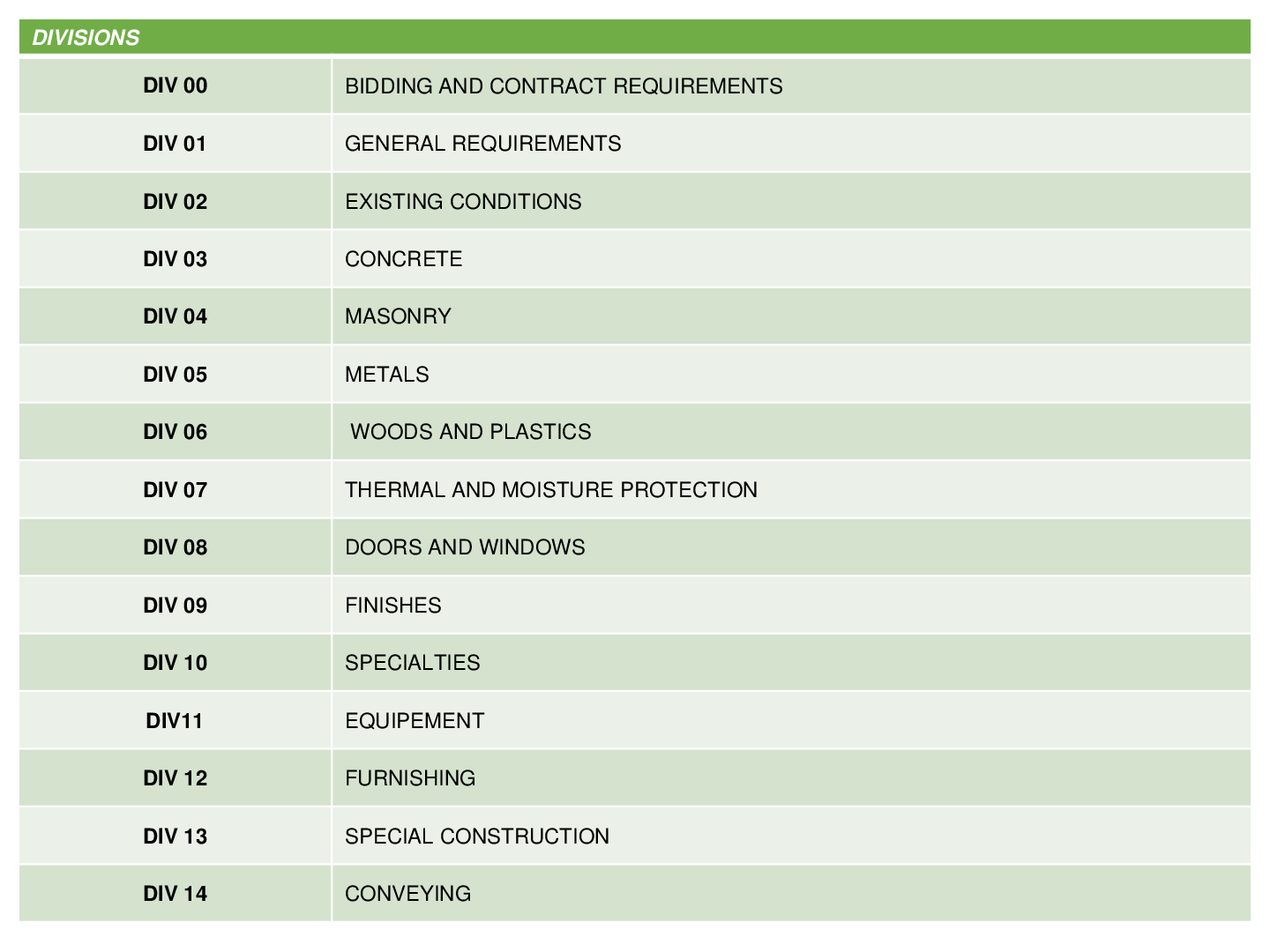

ALE BOARD EXAM REVIEWER DIVISIONS DIV 00 BIDDING AND CONTRACT REQUIREMENTS DIV 01 GENERAL REQUIREMENTS DIV 02 EXISTING CONDITIONS DIV 03 CONCRETE DIV 04 MASONRY DIV 05 METALS DIV 06 WOODS AND ... PLASTICS DIV 07 THERMAL AND MOISTURE PROTECTION DIV 08 DOORS AND WINDOWS DIV 09 FINISHES DIV 10 SPECIALTIES DIV11 EQUIPEMENT DIV 12 FURNISHING DIV 13 SPECIAL CONSTRUCTION DIV 14 CONVEYING DIV 02 : SITE WORKS ATTERBERG LIMITS TESTS PERFORMED ON SOILS PASSING THE NO.40 SIEVE ANSI AMERICAN NATIONAL STANDARDS INSTITUTE ASTM AMERICAN SOCIETY FOR TESTING MATERIALS DPWH DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS (PHIL GOVT) USCS UNIFIED SOIL CLASSIFICATION SYSTEM DIV 02 : SITE WORKS SLURRY WALL DIV 02 : SITE WORKS – EARTHWORKS AASHTO AMERICAN ASSOCIATION OF STATE HIGHWAY AND TRANSPORTATION OFFICIALS CLASSIFIES INORGANIC SOIL FOR SUSTAINABILITYAS SUBGRADE MATERIALS IN TERMS OF GOOD DRAINAGE AND BEARING CAPACITY BOULDERS ABOVE 75MM GRAVEL 75MM TO NO.10 SIEVE COARSE SAND NO.10 TO NO.40 SIEVE FINE SAND NO.40 TO NO.200 SIEVE SILT-CLAY PARTICLES PASSING NO.200 SIEVE ATTERBERG LIMITS TESTS PERFORMED ON SOILS PASSING THE NO.40 SIEVE • LIQUID LIMIT (LL) SOIL CHANGES FROM THE LIQUID STATE TO THE PLASTIC STATE • PLASTIC LIMIT (PL) SILT OR CLAY MATERIAL WILL JUST BEGIN TO CRUMBLE WHEN ROLLED INTO A THREAD • PLASTIC INDEX (PI) LIQUID LIMIT MINUS THE PLASTIC LIMIT; THE RANGE OF WATER CONTENT OVER WHICH SEDIMENT BEHAVES. FILL MATERIALS SOIL, CRUSHED STONE, AND SAND USED TO RAISE AN EXISTING GRADE GRANULAR FILL/ FILTERS SOIL MATERIALS WITH SAND EQUIVALENT OF NOT LESS THAN 50%; USED TO PREVENT THE MOVEMENT OF FINE PARTICLES OUT OF SOILS BORROW FILL SELECTED LABORATORY-APPROVED PIT-RUN GRAVEL, DISINTEGRATED GRANITE, SAND, SHALE, CINDERS OR OTHER SIMILAR MATERIALS BASE COURSE MATERIALS HARD DURABLE FRAGMENTS OF STONE AND A FILLER OF SAND OR OTHER FINELY DIVIDED MINERAL MATTER DIV 02 : SITE WORKS - EARTHWORKS RIPRAP (ROCK LINING) PLACED TO PREVENT EROSION, SCOUR OR SLOUGHING OF A STRUCTURE OR EMBANKMENT GABION SYSTEM WIRE-ENCLOSED RIPRAP; WRAPPING THE RIPRAP ENABLES USE OF SMALLER ROCKS FOR THE SAME RESISTANCE TO DISPLACEMENT BY WATER ENERGY AS LARGER UNWRAPPED RIPRAP. GEOSYNTHETICS CONSISTING OF SYNTHETIC COMPONENTS MADE FOR USE WITH OR WITHIN EARTH MATERIALS A. GEOTEXTILES MOST COMMON GEOSYNTHETICS, AND CONSIST OF WOVEN OR NONWOVEN FABRIC MADE FROM POLYMERIC MATERIALS; REINFORCEMENT, FILTRATION, SEPERATION & IN PLANE DRAINAGE B. GEOMEMBRANES CONTINUOUS POLYMERIC SHEETS THAT ARE IMPERMEABLE DIV 02 : SITE WORKS - EARTHWORKS C. GEOCOMPOSITE CONSIST OF A COMBINATION OF GEOSYNTHETIC COMPONENTS; THE CORE PROVIDES VOID SPACE TO WHICH WATER CAN FLOW IN-PLANE WHILE THE GEOTEXTILE FILTER KEEPS SOIL FROM FILLING THE VOIDS CREATED BY THE CORE. D. GEONET CONSISTS OF A CONTINUOUS EXTRUSION OF POLYMERIC RIBS THAT FORM VOID SPACE THROUGH WHICH PROVIDE IN-PLANE FLOW CAPACITY E. GEOCELLS THREE-DIMENSIONAL PREFABRICATED POLYMERIC SYSTEMS RANGING FROM 100 TO 200 MM (4 TO 8 INCHES) HIGH; TO RAPIDLY STABILIZE SOFT SUBGRADES FOR MOBILIZATION OF LARGE EQUIPMENT SLOPE-EROSION PROTECTION MATERIALS TEMPORARY MATERIALS CONSIST OF OPEN MESH POLYMERIC SYSTEMS, BIODEGRADABLE MESH SYSTEM (E.G., COIR JUTE), OR A COMBINATION OF POLYMERIC AND BIODEGRADABLE MESH. CRIBBING WALL TYPE OF GRAVITY WALL WHICH COMPRISES A SYSTEM OF INTERLOCKING HEADER AND STRETCHER BLOCKS TO RETAIN GRANULAR FILL THAT PROVIDES THE NECESSARY STABILISING MASS TO THE WALL. BIN WALLS MADE FROM 10-FOOT WIDE CORRUGATED STEEL PANELS WHICH ARE EASILY BOLTED TOGETHER, THEN BACKFILLED WITH SOIL; PROTECTS AGAINST SHORE OR BANK EROSION, PROVIDES SUPPORT AND HOLDS BACK ENCROACHING SLOPES DIV 02 : SITE WORKS – TERMITE & BUKBOK PROOFING 1. PHYSICAL BARRIERS TERMITE RESISTANT SAND LAYER OF SAND WITH UNIFORM SIZE PARTICLES; SOMETIMES USED AROUND THE FOUNDATION OF A HOME DURING CONSTRUCTION TERMITE MESH STEEL MESH PRODUCT THAT IS FINE ENOUGH TO KEEP EVEN TINY TERMITES FROM PASSING THROUGH IT HOME CONSTRUCTION HOMES ARE SOMETIMES DESIGNED ON HIGH CONCRETE PILLARS TO PHYSICALLY SEPARATE THE HOME FROM THE DISTANCE TERMITES CAN TRAVEL FROM THEIR COLONY 2. CHEMICAL BARRIERS PRE-CONSTRUCTION CHEMICAL BARRIERS APPLIED DURING CONSTRUCTION, TO THE SOIL AND FOUNDATION; HORIZONTAL BARRIERS (SLAB TREATMENT, BASEMENT AND CRAWL SPACES); VERTICAL BARRIES 3. COLONY ELIMINATION (BAIT) SYSTEM THE SYSTEM EMPLOYS BAITING AND MONITORING DEVICES, INSTALLED WHERE EVIDENCE OF INFESTATION IS FOUND DIV 02 : SITE WORKS – SEQUENCE CLEARING VERIFICATION RELOCATION FENCING UTILITIES TEMPORARY FACILITIES LAYOUTING TAGGING STAKING-OUT AND BATTER BOARD EXCAVATION DIV 02 : SITE WORKS 1.20 – 3.00 M DISTANCE FROM EXCAVATION TO BATTERBOARDS EVERY 150 MM A FILL SHOUL BE COMPACTED 3 MIN. NUMBER OF A BORE FOR A SOIL TEST; (GET SAMPLE WHERE THE SOIL IS SOFT) • WHEN OVER EXCAVATE, FILL IT WITH GRAVEL • IF JOBSITE IS SLOPING, START THE EXCAVATION AT THE REAR. DIV 03 : CONCRETE – CEMENTING MATERIALS ACI AMERICAN CONCRETE INSTITUTE AASHTO AMERICAN ASSOCIATION OF STATE HIGHWAY AND TRANSPORT OFFICIAL M173-84 CONCRETE JOINT SEALER ASTM C881 SPECIFICATION COOVERS 2 COMPONENT MATERIAL SUITABLE FOR USE ON DRY OR DAMP SURFACES DIV 03 : CONCRETE – CEMENTING MATERIALS 1. LIME ONE OF THE OLDEST MANUFACTURED BUILDING MATERIALS USED AS A MORTAR AND PLASTER BY ALL THE EARLY CIVILIZATIONS QUICKLIME CARBONATES DECOMPOSE INTO CARBON DIOXIDE, WHICH IS EXPELLED, AND CALCIUM OXIDE (CAO) SLAKING OR HYDRATION PROCESS OF QUICKLIME MIXED WITH WATER SLAKED LIME / HYDRATED LIME QUICKLIME THAT UNDERGO SLAKING/ HYDRATION HYDRAULIC LIME LIME CHICH IS SET UNDER WATER 2. GYPSUM/ PLASTER GYPSUM ROCK IS GROUND FINE AND HEATED (CALCINED) TO BETWEEN 325 °F. TO 340 °F. WHEN IT LOSES ABOUT THREE-FOURTHS OF ITS COMBINED WATER 3. CEMENT (1500 kg/m³) FIRST DEVELOPED BY ROMANS BY MIXING SLAKED LIME AND POZZOLANAWHICH HARDENED UNDER WATER POZZOLANA VOLCANIC ASH SMEATON (1756) REDISCOVERED HYDRAULIC CEMENT ASPDIN (1824) INVENTED AND PATENTED PORTLAND CEMENT PORTLAND CEMENT OBTAINED BY FINELY PULVERIZING CLINKER PRODUCED BY CALCINING A PROPORTIONED MIXTURE OF ARGILLACEOUS (SILICA, ALUMINA) AND CALCAREOUS (LIME) MATERIALS WITH IRON OXIDE PORTLAND CEMENT TYPES • TYPE I: GENERAL PURPOSE USED FOR MOST PURPOSES IN CONSTRUCTION; 28 DAYS CURING • TYPE II: MODERATE SULFATE RESISTANCE USED IN CONTACT WITH WATER WITH SULFATE • TYPE III: HIGH EARLY STRENGTH FAST CURING, 2-3 DAYS • TYPE IV: LOW HEAT OF HYDRATION SLOW CURING; PREVENTS CRACKING; FOR DAMS & MASSIVE STRUCTURES • TYPE V: SULFATE RESISTANCE FOR AREAS WITH HIGH SULFATE CONCENTRATION DIV 03 : CONCRETE– CEMENTING MATERIALS AIR ENTRAINING TYPE 1-3 WITH AIR ENTRAINING WHITE PORTLAND CEMENT PRE-CAST CONCRETE WORKS BLENDED CEMENT 85% TOTAL ENERGY; CEMENT MIXED WITH OTHER ASPHALT CEMENT WITH BITAMOUS; PYROPROCESSING SUBJECTED TO HIGH TEMP. TO BRING CHEMICAL & PHYSICAL CHANGE HYDRATION ACT WHEN CEMENT REACTS WITH WATER, IT GENERATES HEAT STORAGE OF CEMENT • STORED IN SHED WITH A WOOD FLOOR RAISED ABOUT 300MM (12”) FROM THE GROUND • USED AS SOON AS POSSIBLE AFTER DELIVERY • PILES SHOULD BE LIMITED TO 12 SACKS IN HEIGHT •AVOID CONTACT OF DAMPNESS •SHOULD BE PROTECTED AT THE BLDG SITE WAREHOUSE SET WHEN THE CEMENT IS STORED IN HIGH PILES FOR LONG PERIODS, THERE IS A TENDENCY FOR THE LOWER LAYERS TO HARDEN CAUSED BY THE PRESSURE ABOVE DIV 03 : CONCRETE CONCRETE MIXTURE OF CEMENT, GRAVEL & WATER; PLASTIC MASS WHICH CAN BE CAST, MOLDED OR FORMED INTO PREDETERMINED SIZE OR SHAPE; UPON HYDRATION, BECOMES STONE-LIKE IN STRENGTH, HARDNESS AND DURABILITY SETTING HARDENING OF A CONCRETE MORTAR, STUCCO OR CEMENT PLASTER CONCRETE WHEN MIXED WITH WATER AND A FINE AGGREGATE OF LESS THAN 6MM (1⁄4“) REINFORCED CONCRETE CONCRETE STRENGTHENED BY EMBEDDED STEEL PLAIN OR MASS CONCRETE CONCRETE WITHOUT REINFORCEMENT QUALITIES OF GOOD CONCRETE • STRONG • DURABLE • UNIFORM QUALITY • THOROUGHLY SOUND MATERIALS OF CONCRETE 1. CEMENT SHOULD BE HIGH- GRADE TYPE 1 PORTLAND CEMENT TYPE C-150 CONFORMING TO THE “STANDARD SPECIFICATIONS AND TEST FOR PORTLAND CEMENT” OF THE AMERICAN SOCIETY FOR TESTING MATERIALS (ASTM) 1 CU. FT., 94 LBS APPROXIMATELY EQUIVALENT OF A BAG OF CEMENT 2. AGGREGATES INERT MATERIAL FILLERS; 60-70% VOLUME OF CONCRETE; NATURAL MATERIALS FINE AGGREGATES SMALLER THAN 6MM (1⁄4”) IN SIZE; SAND, STONE SCREENINGS COARSE AGGREGATES AGGREGATE LARGER THAN 6MM (1⁄4”) IN SIZE; CRUSHED STONES, GRAVEL; NOT EXCEED 25MM (1”) IN SIZE FOR REINFORCED BEAMS, FLOOR SLABS, & THIN WALLS; MAY RANGE UP TO 50MM (2”) FOR LESS HIGHLY REINFORCED PARTS SUCH AS FOOTING, THICK WALLS AND MASSIVE WORK SPECIAL AGGREGATES LIGHTWEIGHT, NAILABLE CONCRETE; THERMAL INSULATING CONCRETE; SUCH AS CINDERS, BLAST FURNACE SLAG, EXPANDED SHALE, PERLITE, ETC. DIV 03 : CONCRETE 3. WATER SHOULD BE FREE FROM OTHER DELETERIOUS SUBSTANCES; CLEAR AND CLEAN; BINDS THE ENTIRE MASS TOGETHER UPON HARDENING; THE STRENGTH OF THE MIXTURE THEREFORE DEPENDS DIRECTLY UPON THE STRENGTH OF THE PASTE. IF THERE BE AN EXCESS OF WATER THE PASTE BECOMES THIN AND WEAK AND ITS HOLDING POWER IS REDUCED; VARIES FROM 5 TO 7 GALLONS; THE LESS WATER USED IN MIXING, THE BETTER THE QUALITY OF CONCRETE WATER CEMENT RATIO AMOUNT OF WATER USED PER BAG OF CEMENT PLASTIC AND WORKABLE IDEAL MIX; IT SHOULD NOT BE TOO DRY THAT IT BECOMES TOO DIFFICULT TO PLACE IN THE FORMS, NOR TOO WET THAT SEPARATION OF THE INGREDIENTS RESULT SLUMP TEST measuring the consistency of a concrete mix; “state of fluidity of the mix”; DIV 03 : CONCRETE PROPORTIONING OF CONCRETE • USE OF GOOD QUALITY MATERIALS • DETERMINE THE STRENGTH OF CONCRETE USING WATER CEMENT RATIO • DETERMINE THE CONSISTENCY OF THE MIX USING SLUMP TEST • ADD CORRECT PROPORTIONS OF AGGREGATES • MAKE A MIX THAT’S WORKABLE, NOT HARSH CLASS PROPORTION CEMENT IN A BAG SAND GRAVEL DESCRIPTION PSI AAA 1 : 1 : 2 0.50 1.00 PRE-STRESSED AND POSTTENSIONED AA 1 : 1½ : 3 12 9.5 0.50 1.00 FOR CONCRETE UNDER WATER, RETAINING WALLS 4000 A 1 : 2 : 4 9 7 0.50 1.00 FOR SUSPENDED SLABS, BEAMS, COLUMNS, ARCHES, STAIRS, WALLS OF 100MM (4”) THICKNESS 3500 B 1 : 2 ½ : 5 7.5 6 0.50 1.00 FOR WALLS THICKER THAN 100MM (4”), FOOTINGS, STEPS, REINFORCED CONCRETE SLABS ON FILL 3000 C 1 : 3 : 6 6 5 0.50 1.00 FOR CONCRETE PLANT BOXES, AND ANY NON-CRITICAL CONCRETE STRUCTURES LIKE PARAPET WALLS 2500 D 1 : 3.5 : 7 5 4 0.50 1.00 FOR PLANBOXES, WALKWAYS AND LEAN CONCRETE 2000 DIV 03 : CONCRETE - MIXING OF CONCRETE 1. MACHINE MIXING THE MIXING OF EACH BATCH SHOULD CONTINUE NOT LESS THAN ONE MINUTE AFTER ALL THE MATERIALS ARE IN THE MIXER AND WHENEVER PRACTICABLE BATCH MIXERS SUFFICIENT MATERIALS ARE PLACED AT ONE TIME TO MAKE A CONVENIENT SIZE BATCH OF CONCRETE CONTINUOUS MIXERS MATERIALS ARE FED CONSTANTLY AND FROM WHICH THE CONCRETE IS DISCHARGED IN A STEADY STREAM 2. HAND MIXING MUST BE DONE ON A WATER-TIGHT PLATFORM; CEMENT AND FINE AGGREGATE SHALL FIRST BE MIXED DRY THEN WATER AND COARSE AGGREGATE SHALL BE ADDED; PLACE 1 TO 3 HOURS AFTER MIXING; REGAGING OR RETEMPERING OF CONCRETE THAT HAS BEEN ALLOWED TO STAND MORE THAN 1⁄2 HOUR IS NOT TO BE PERMITTED REGAGING/ RETEMPERING TO MIX (CONCRETE OR MORTAR) AGAIN WITH OR WITHOUT ADDITIONAL WATER AFTER INITIAL SET HAS TAKEN PLACE TRANSPORTING AND PLACING OF CONCRETE • FRESH CONCRETE SHOULD BE TRANSPORTED FROM THE MIXER AS RAPIDLY AS PRACTICABLE BY METHODS THAT WILL PERMIT THE PLACING OF THE CONCRETE IN THE FORMS BEFORE INITIAL SET OCCURS AND WITHOUT LOSS OR SEPARATION OF MATERIALS. • SHOULD BE FAIRLY CONTINUOUS AND UNINTERRUPTED • TIME OF TRANSPORTATION SHOULD NOT EXCEED 30 MINUTES • THE SLOPE FOR CHUTES SHOULD NOT BE MORE THAN 1 VERTICAL TO 2 HORIZONTAL OR LESS THAN 1 VERTICAL TO 3 HORIZONTAL • SHOULD NEVER BE ALLOWED TO DROP FREELY OVER 5 FT. FOR UNEXPOSED WORK AND OVER 3 FT. FOR EXPOSED WORK • BEFORE PLACING CONCRETE, THE FORMS SHALL BE CLEANED AND INSPECTED, SURFACES WETTED OR OILED, AND REINFORCEMENT PROPERLY SECURED DIV 03 : CONCRETE SHRINKAGE CRACKS LIKELY TO OCCUR AT JOINTS WHERE FRESH CONCRETE IS JOINED TO CONCRETE WHICH HAS ALREADY SET, AND HENCE IN PLACING THE CONCRETE, CONSTRUCTION JOINTS SHOULD BE MADE ON HORIZONTAL AND VERTICAL LINES. CURING HARDENING IS A RATHER SLOW PROCESS IN WHICH THE CEMENT AND WATER UNITE TO FORM COMPOUNDS THAT GIVE STRENGTH AND DURABILITY TO THE CONCRETE; CONTINUES AS LONG AS THE TEMPERATURES ARE FAVORABLE AND MOISTURE IS PRESENT 3 MAIN FACTORS THAT AFFECT HARDENING 1. AGE OR TIME 2. TEMPERATURE 3. MOISTURE CURING OF CONCRETE • REMOVAL OF FORMS AT PRESCRIBED TIME • COVERING THE CONCRETE • SPRINKLING WITH WATER • USING CURING COMPOUNDS/ ADMIXTURES DIV 03 : CONCRETE DIV 03 : CONCRETE DIV 03 : CONCRETE DIV 03 : CONCRETE - ADMIXTURES ADMIXTURES SUBSTANCES ADDED TO CEMENTS, MORTARS, AND CONCRETE FOR THE PURPOSE OF IMPROVING OR IMPARTING PARTICULAR PROPERTIES; GROUP INTO 3 CATEGORIES: FOR MIXING INTO CONCRETE, MIXING INTO MORTAR AND SURFACE APPLICATION OR FINISH; COMES IN POWDER, PASTE, AND LIQUID FORM ACCELERATORS SPEED UP SETTING TIME; PRINCIPAL INGREDIENTS ARE CALCIUM CHLORIDE; MAX AMOUNT ADDED IS 2 LBS. PER BAG OF CEMENT RETARDERS SLOW DOWN THE HYDRATION OF CEMENT DURING VERY HOT WEATHER; PRINCIPAL INGREDIENTS INCLUDE ZINC OXIDE, CALCIUM LIGNOSULFONATE, DERIVATIVES OF ADIPIC ACID AIR-ENTRAINING AGENT INTRODUCE MINUTE AIR BUBBLES TO GREATLY INCREASE THE RESISTANCE OF CONCRETE TO FREEZING AND THAWING, INCREASE PLASTICITY AND REDUCE BLEEDING; MAY CAUSE SOME LOSS OF STRENGTH INERT, FINELY DIVIDED POWDERS SUCH AS POWDERED GLASS , SILICA SAND, STONE DUST, HYDRATED LIME ADDED TO IMPROVE WORKABILITY WATERPROOFING COMPOUNDS PERMIABILITY-REDUCING; REDUCE THE CAPILLARY ATTRACTION OF THE VOIDS IN THE CONCRETE OR MORTAR; DOES NOT RENDER CONCRETE WATERPROOF COLORED PIGMENTS GIVE COLOR TO CONCRETE FLOORS • DRY-CAST, BROADCAST, OR DUST ON – FOR SURFACE COLORING; THERY ARE DUSTED IN THE SURFACE • INTEGRAL COLORS – FOR BODY COLORING; INCORPORATED IN THE MORTAR TOPPING SUPERPLASTICIZER ALLOW REDUCTION IN WATER CONTENT BY 30% OR MORE; SELF LEVELING CONCRETE DIV 03 : CONCRETE – FORMS LUMBER FORMS SHOULD ONLY BE PARTIALLY SEASONED PLYWOOD FORMS WORKS BEST WHERE A SMOOTH SURFACE IS REQUIRED; SHOULD BE WATERPROOF; GRADE A; 12 MM THK STEEL FORMS IN THE FORM OF PANS CONCRETE JOIST CONSTRUCTION; STEEL DECKING OR CORRUGATED STEEL FOR CONCRETE SLABS AND SLAB-AND-JOIST CONSTRUCTION PLASTIC FORMS POLYSTYRENE FORMS ARE NOW AVAILABLE FOR CONCRETE WORK DIV 03 : CONCRETE– PROCESSED CONCRETE AEROCRETE A LIGHT–WEIGHT, EXPANDED STRUCTURAL CONCRETE PRODUCED BY ADDING A SMALL AMOUNT OF METALLIC ALUMINUM POWDER TO THE MIXTURE OF PORTLAND CEMENT AND SAND OF CINDERS; HAS EXCELLENT FIRERESISTIVE QUALITIES GUNITE “CEMENT GUN”; DEPOSITED UNDER HIGH PNEUMATIC PRESSURE WITH A MACHINE ; IDEAL FOR SWIMMING POOL CONSTRUCTION; PORETE PORTLAND CEMENT CONCRETE TO WHICH A CHEMICAL FOAM IS ADDED TO GENERATE GASES IN THE PROCESS OF DEPOSITION, RESULTING IN LIGHT WEIGHT PRECAST OR SHOP- MADE UNIT IN BOTH HOLLOW AND SOLID FORMS. HAYDITE CONCRETE PROCESSED CONCRETE ADDED WITH LIGHTWEIGHT AGGREGATE * 2ND PIC IS HAYDITE ROCK – THE LIGHTWEIGHT AGGREGATES DIV 04 : MASONRY – MORTAR AND PLASTERS CEMENT MORTAR MIX USED TO GLUE MASONRY UNITS TO EACH OTHER; PROPORTIONED MIXTURE OF CEMENT, FINE AGGREGATE AND WATER 1 ST CLASS MORTARS 1:3 RATIO; 1 PART OF CEMENT TO 3 PARTS OF SAND RUBBLE STONEWORK 1 : 4 RATIO TOP SURFACE OF FLOORS & WALKS 1:1 OR 1:1/2 PLASTER A MORTAR APPLIED TO WALL SURFACE AS A PREPARATION OR A HARD FINISH COAT TWO-COAT • SCRATCH & BROWN COATS ARE COMBINED INTO ONE • FINISH COAT – FINAL COAT THREE-COAT • SCRATCH COAT – BINDING COAT • BROWN COAT – STRAIGHTENING COAT • FINISH COAT – FINAL COAT 1. LIME PLASTER LIME PUTTY (HYDRATED LIME & WATER) SCRATCH COAT : 1 PART LIME PUTTY, 1 PART PORTLAND CEMENT OR KEENE’S CEMENT, 2-3/4 PARTS SAND BY WEIGHT. 1:1:2 ¾ BROWN COAT : 1 PART LIME PUTTY, 1 PART PORTLAND CEMENT OR KEENE’S CEMENT, 3 PARTS SAND BY WEIGHT. 1:1:3 FINISH COAT: • HARD FINISH : 1 PART LIME PUTTY, 1/3 GYPSUM PLASTER BY VOLUME 1:1/3 • SAND FLOAT : 1 PART LIME PUTTY, 1⁄4 GYPSUM PLASTER, 2 PARTS SAND BY VOLUME 1:1/4:2 2. GYPSUM PLASTER PLASTER OF PARIS MIXED WITH CLAY, LIME AND OTHER MATERIALS IN COMBINATIONS COVERED BY TRADEMARKS OR PATENTS 3. HIGH-STRENGTH GYPSUM PLASTER MIXED TO MEET ESTABLISHED STANDARDS 4. FIBERED GYPSUM PLASTER GYPSUM PLASTER PREMIXED WITH FIBERS 5. PREPARED GYPSUM PLASTER GYPSUM PLASTER MIXED WITH FINE WHITE SAND; FOR INTERIOR WALLS & CEILINGS DIV 04 : MASONRY – MORTAR AND PLASTERS 6. BONDING PLASTER GYPSUM PLASTER MIXED WITH INGREDIENTS DEVELOP MORE ADHESIVE STRENGTH; INTERIOR FINISH FOR SMOOTH CONCRETE WALLS OR CEILINGS 7. LIGHTWEIGHT GYPSUM PLASTER, FIRE-RESISTANT PLASTER GYPSUM PLASTER MIXED ON THE JOB WITH WATER, PERLITE, VERMICULITE OR OTHER SUITABLE MINERAL AGGREGATE; FOR INTERIOR USE ONLY 8. KEENE’S CEMENT PLASTER OF PARIS MIXED WITH ALUM OR BORAX OR OTHER MATERIALS AND BURNED (CALCINED) AT 932°F; FOR INTERIOR USE ONLY 9. PLASTER OF PARIS FOR ORNAMENTAL PLASTER WORK AND CASTINGS 10. MOLDING PLASTER FOR ORNAMENTAL PLASTER WORK AND CASTINGS.; MIX WITH WATER AS PER MANUFACTURER’S DIRECTIONS 11. ACOUSTIC PLASTER FOR ACOUSTIC TREATMENT OF INTERIOR WALLS AND CEILINGS; APPLIED ON GYPSUM PLASTER BASE COATS 12. PORTLAND CEMENT PLASTER MIXED WITH WATER, SAND AND LIME PUTTY; USED FOR TWO AND THREECOAT FINISH SURFACES FOR EXTERIOR AND INTERIOR WALLS AND CEILINGS 13. SGRAFFITO HIGHLY DECORATIVE TYPE OF PLASTER WORK DEVELOPED IN ITALY DURING THE RENAISSANCE; PRODUCE A THREE-DIMENSIONAL COLORED DESIGN DIV 03 : MASONRY MASONRY IS A BUILT-UP CONSTRUCTION OR COMBINATION OF BUILDING MATERIALS AS CLAY, CONCRETE, OR STONE SET IN MORTAR; OR PLAIN CONCRETE BRICKS BLOCK USED TO MAKE WALLS, PAVEMENTS & OTHER ELEMENTS IN MASONRY CONSTRUCTION COMMON OR BUILDING BRICK USED FOR ALL PURPOSES, INCLUDING FACING FACING BRICK SPECIALLY PROCESSED TO GIVE CERTAIN SPECIFIC SURFACE CHARACTERISTICS; USED FOR EXPOSED MASONRY SURFACES GLAZED BRICK HAVE A SMOOTH OUTER SURFACE; THEY ARE LOAD BEARING, FIRE RESISTING, AND IMPERVIOUS; USUALLY FORMED WITH VERTICAL HOLLOW CORES THROUGH THE BODY WITH SCORING ON THE BACK FIRE (REFRACTORY) BRICK ORDINARILY MADE FROM A MIXTURE OF FLINT CLAY AND PLASTIC CLAY; USED FOR THE LINING OF FURNACES, FIREPLACES, AND CHIMNEYS BED – HORIZONTAL SURFACES ON WHICH THE STONES OR BRICKS OF WALLS LIE IN THE COURSES COURSE – CONTINUOUS LAYER OF BRICKS, STONES, OR OTHER MASONRY UNITS WYTHE OR TIER – EACH CONTINUOUS, VERTICAL SECTION OF THE WALL, ONE MASONRY UNIT THICK CULL – REJECTED AS BEING OF INFERIOR QUALITY FLASHING – FIRING BRICK UNITS ALTERNATELY VARY THEIR FACE COLOR CLINKER – DENSE , HARD-BURNED BRICK ESPECIALLY FOR PAVING SOAP – BRICK OR TILE HAVING NORMAL SIZE DIMENSION BAT – BRICK CUT TRANSVERSELY SO AS TO LEAVE ONE END WHOLE GAUGE – CHIP OR RUB STONES OR BRICKS TO CERTAIN SIZE OR SHAPE FBX – USE WHERE A MINIMUM VARIATION IN SIZE, COLOR RANGE & MECH. PERFECTION ARE REQUIRED FBS – GREATER VARIATION IN SIZE ARE PERMITTED THAN FOR TYPE FBX FBA – USE WHERE PARTICULAR EFFECTS ARE DESIRED RESULTING NON-UNIFORMITY IN SIZE, COLOR AND TEXTURE PROCESS OF FORMING BRICK SOFT-MUD PROCESS MOLDING WET CLAY, 20%-30% MOISTURE CONTENT STIFF-MUD PROCESS EXTRUDING STIFFBUT PLASTIC CLAY WITH 12%-15% MOISTURE CONTENT WATER-STRUCK BRICK WET CLAY WITH A MOLD LUBRICATED WITH WATER SAND-STRUCK BRICK WET CLAY MOLD LINED WITH SAND DRY-PRESS PROCESS RELATIVELY DRY CLAY; 5%-7% MOISTURE CONTENT DIV 04 : MASONRY BOND CONNECTION BETWEEN BRICKS; AKA BREAKING JOINT STRETCHER SOLDIER HEADER ROWLOCK SAILOR SHINER DIV 04 : MASONRY QUOINS The corner stones at the angles of buildings; usually rusticated DIV 04 : MASONRY MORTAR JOINTS ARE USUALLY FROM 4.5MM (3/16”) TO 12MM (1⁄2”) TYPES OF MORTAR TYPE M MORTAR (HIGH-STRENGTH) – HAS LESS WORKABILITY THAN S AND N, FOR MASONRY CONSTRUCTION BELOW GRADE TYPE S MORTAR (MEDIUM HIGH STRENGTH) – FOR MASONRY (BOND & LATERAL STRENGTH) TYPE N MORTAR (MEDIUM STRENGTH) – GENERAL PURPOSE – FOR EXPOSED MASONRY ABOVE GRADE TYPE O MORTAR (LOW STRENGTH) – FOR INTERIOR NON-LOAD BEARING WALLS TYPE K MORTAR (VERY LOW STRENGTH) – SUITABLE ONLY FOR USE IN INTERIOR NON-LOADBEARING WALL WHERE PERMITTED BY BUILDING CODE DIV 04 : MASONRY STONE IS LARGELY USED AS A SURFACE FINISHING MATERIAL FOR BOTH THE EXTERIOR AND INTERIOR OF BUILDINGS SEDIMENTARY ROCK FORMED BY THE DEPOSITION OF SEDIMENT EG. LIMESTONE, TRAVERTINE, DOLOMITE, OOLITE, SANDSTONE, BLUESTONE, BROWNSTONE, SOAPSTONE METAMORPHIC ROCK HAS UNDERGONE A CHANGE IN STRUCTURE, TEXTURE, OR COMPOSITION DUE TO NATURAL AGENCIES,SUCH AS HEAT AND PRESSURE EG. MARBLE, VERD ANTIQUE, SLATE, QUARTZITE, GNEISS IGNEOUS ROCK FORMED BY THE CRYSTALLIZATIO N OF MOLTEN MAGMA EG. GRANITE, OBSIDIAN, MALACHITE, SERPENTINE RUBBLE STONE DELIVERED FROM THE QUARRIES ROUGH AND IRREGULAR SHAPE DIMENSION STONE CUT INTO SPECIFIC SIZE, SQUARED TO DIMENSIONS, AND TO A SPECIFIC THICKNESS STONE WORK BASED ON THE SHAPE AND THE SURFACE TREATMENT OF FINISH OF THE STONE 1. RUBBLEWORK - MASONRY OF ROUGH, UNDRESSED STONES 2. ASHLAR - SQUARED STONES IN REGULAR COURSES, IN CONTRADISTINCTION TO RUBBLE WORK RANDOM COURSED BROKEN RANGE RANDOM COURSED DIV 04 : MASONRY CONCRETE HOLLOW BLOCK • HOLLOW MASONRY UNIT, WITH TWO OR THREE CELLS OR CORES • HEIGHT OF 200MM (8”) X LENGTH OF 400MM (16”) • STANDARD CHB SIZES THICKNESS: 100MM (4”)ONLY FOR INTERIOR PARTITION, 150MM (6”), 200MM (8”) • 10MM (3/8”) THICK MORTAR FOR HORIZONTAL& VERTICAL JOINTS • REINFORCEMENT FOR 4” AND 6” CHB SHALL BE 10MMØ VERTICAL BARS AT 600MM ON CENTERS AND 10MMØ HORIZONTAL BARS EVERY THIRD COURSE • PROVIDE LINTEL BEAM EVERY TWELFTH COURSE AND A CONCRETE COLUMN STIFFENER AT EVERY 4.80 METERS LENGTH DIV 04 : MASONRY DURISOL BLOCK • LIGHTWEIGHT BLOCK MADE FROM FIBER AND CEMENT • TWO-CORE, 100MM (4”) OR 150MM ( 6”) X 87MM (7- 1/2”) X 600MM (24”) • REINFORCEMENT SHALL BE 10MMØ VERTICAL BARS AT 720MM (36”) ON CENTER AND AT EVERY 4TH COURSE • CORES ARE SOLIDLY FILLED WITH CEMENT MORTAR PLASTER BLOCK • KNOWN AS GYPSUM PARTITION BLOCKS • USED FOR LIGHTWEIGHT, FIRE-RESISTANT INTERIOR PARTITIONS AND FOR FURRING AND FIREPROOFING COLUMNS • MANUFACTURED ONLY WITH A 50MM (2”) THICKNESS STRUCTURAL CLAY TILE • OPEN AT TWO ENDS WITH INTERIOR WEBS OR PARTITIONS • 19MM (3⁄4”) TO 25MM (1”) DIVIDING THE BLOCK INTO LONGITUDINAL CELLS • CLASSIFIED INTO: a. LOAD-BEARING WALL TILE --- 300MM X 300MM X 300MM (12” X 12” X 12”) B. NON-LOAD BEARING, FIREPROOFING, PARTITION, AND FURRING TILE --- 100MM (4”) OR 125MM (5”) X 200MM X 300MM PAVEMENTS DIV 04 : MASONRY DIV 05 : METALS 1. ALUMINUM • SOFT, NONMAGNETIC SILVERY METAL • LOW MELTING POINT; HIGH THERMAL AND ELECTRICAL CONDUCTIVITY • MODERATELY HIGH COEFFICIENT OF EXPANSION • COMBINES WITH OXYGEN TO FORM ALUMINUM OXIDE, A TRANSPARENT FILM THAT MAKES IT \CORROSION RESISTANT • EASILY WORKED: CAN BE HOT OR COLD ROLLED, EXTRUDED, FORGED, PRESSED, DRAWN, MOLDED, STAMPED, BENT AND SHAPED • CAN BE RIVETED, BOLTED, WELDED, BRAZED AND SOLDERED • ROD, BAR, EXTRUSION, CASTING, SHEET, STRIP, ETC. EXTRUSION PROCESS OF SHAPING MATERIAL BY FORCING IT FORGING MANUFACTURING PROCESS INVOLVING THE SHAPING OF METAL USING LOCALIZED COMPRESSIVE FORCES; THE BLOWS ARE DELIVERED WITH A HAMMER TYPES OF ALUMINUM A. ALCLAD CORROSION-RESISTANT ALUMINIUM SHEET FORMED FROM HIGH-PURITY ALUMINIUM SURFACE LAYERS METALLURGICALLY BONDED B. ALUMINUM SHEET & STRIP USED FOR ROOFING, FLASHING, GUTTER, ETC; >0.005” C. ALUMINUM FOIL ROLLED TO A THICKNESS OF 0.005” D. CORRUGATED ALUMINUM SPECIAL ALUMINUM ALLOYS SPECIFICALLY DEVELOPED FOR THIS PURPOSE E. STRUCTURAL ALUMINUM ALUMINUM GIRDERS AND COLUMNS SHOW INCREASED EFFICIENCY BECAUSE IT IS LIGHTWEIGHT; BUCKLING IS A POSSIBILITY BECAUSE OF ITS MODULUS OF ELASTICITY F. ALUMINUM DOORS & WINDOWS FABRICATED FROM EXTRUSIONS AND ROLLED SHAPES G. ALUMINUM PANELS & SANDWICH PANELS PRE-FABRICATED UNITS; IN 600MM, 900MM, AND 1200MM WIDTHS FOR INTERIOR PARTITIONS AND DIVIDERS H. ORNAMENTAL ALUMINUM FOR RAILINGS, GRILLES, SCREENS, ETC. I. ALUMINUM MESH & WIRE CLOTH FOR FENCING AND INSECT SCREENING DIV 05 : METALS TYPES OF ALUMINUM FINISHES A. MECHANICAL FINISHES BY GRINDING POLISHING, SCRATCHING, SANDBLASTING, EMBOSSING, OR OTHER TREATMENT OF THE SURFACE B. CHEMICAL FINISHES ETCHING, CLEANING, OR POLISHING; OXIDIZING THE SURFACE WITH ALUMINUM OR OTHER METALLIC OXIDES C. ELECTROLYTIC FINISHES AKA ANODIZED FINISHES; PROTECTIVE COATING OF OXIDE ON ITS SURFACE; CAN BE OPAQUE OR TRANSPARENT; MOST STABLE FADE RESISTANCE IS ARCHITECTURAL GOLD D. ELECTROPLATING COVERED WITH A PROTECTIVE OR DECORATIVE FILM OR ANOTHER METAL, USUALLY BY ELECTRODEPOSITION. F. PORCELAIN OR VITREOUS ENAMEL FINISH FORMS A HARD, RESISTANT SURFACE; COLORS ARE GLASSY G. PAINT CAN BE LACQUER AND ENAMEL BUT NOT LEAD BASE H. POWDER COAT OLYESTER BASED COATING THAT USES UNIFORMLY SIZED MICRO-BEADS OF POLYESTER, ELECTROSTATICALLY CHARGED 2. IRON • TOUGH, AND MALLEABLE SILVERY-WHITE • SOFT AND DUCTILE • EASILY MAGNETIZED • OXIDIZES RAPIDLY IN AIR • HARDENED BY HEATING AND SUDDEN COOLING • MORE PLIABLE OR MORE WORKABLE BY HEATING AND SLOW COOLING • BECOMES BRITTLE AT A LOW TEMPERATURE • RED HEAT IT IS SOFT, AND AT WHITE HEAT IT CAN BE WELDED CRUDE OR PIG IRON COMMERCIAL FORM IN WHICH IRON IS FIRST PREPARED TYPES OF ALUMINUM A. CAST IRON IRON-CARBON ALLOY THAT CONTAINS MORE THAN 1.7% CARBON; POURED WHILE MOLTEN INTO FORMS; TOO HARD AND BRITTLE TO BE SHAPED BY HAMMERING, ROLLING, OR PRESSING; FOR PIPING AND FITTINGS, ORNAMENTAL IRONWORK, HARDWARE, ETC.; USE IN HEAVY MACHINERY & INDUSTRY (COMPRESSIVE STRENGTH DIV 05 : METALS B. WROUGHT IRON ALMOST PURE IRON WITH LESS THAN 0.1% CARBON ; CONTAINS 2.5% OF SLAG (IRON SILICATE); HAS GOOD MACHINABILITY AND CAN BE FORGED, BENT, ROLLED, DRAWN, AND SPUN; WROUGHT IRON PIPE,CHAIN, SHEET, AND ORNAMENTAL IRONWORK 3. STEEL • ALLOYS OF IRON AND CARBON • CAN BE WROUGHT, ROLLED, CAST, AND WELDED, BUT NOT EXTRUDED • IN THE PLAIN OR STRAIGHT CARBON STEELS, THE IRON IS ALWAYS IN EXCESS OF 95% • DO NOT CONTAIN MORE THAN 2% CARBON TYPES OF STEEL A. WROUGHT CARBON STEELS: STRUCTURAL STEEL A MEDIUM CARBON STEEL WITH ITS CARBON CONTENT CONTROLLED TO GIVE BOTH THE STRENGTH AND DUCTILITY B. WROUGHT CARBON STEELS: REINFORCEMENT OF CONCRETE DEFORMED BARS OF VARYING GRADES AND DIAMETERS C. WROUGHT CARBON STEELS: SHEET & STRIP GENERALLY CONTAINING ABOUT 0.15% CARBON AND NOT EXCEEDING 0.25%; 12” OR LESS WIDE D. WROUGHT CARBON STEELS: CORRUGATED STEEL RIGIDIZED SHEET FABRICATED FROM LOW-CARBON COLD OR HOT-ROLLED STEEL SHEETS E. WROUGHT CARBON STEELS: STEEL MESH & WIRE CLOTH USED FOR CONCRETE REINFORCEMENT, LATH FOR PLASTER, STUCCO, AND CEMENT, FENCING, INSECT SCREENS F. WROUGHT CARBON STEELS: STEEL WINDOW & DOORS G. WROUGHT CARBON STEELS: HARDWARE NAILS. SCREWS, RIVETS ETC. H. ALLOY STEELS MANGANESE, SILICON, ALUMINUM, TITANIUM, AND MOLYBDENUM HAVE BEEN ADDED; ALLOYING ELEMENTS ARE ADDED TO INCREASE STRENGTH, HARDNESS, EASE AND DEPTH OF HARDENABILITY, PERFORMANCE AT HIGH OR LOW TEMPERATURES, ELECTROMAGNETIC PROPERTIES, WEAR RESISTANCE, ELECTRICAL CONDUCTIVITY OR RESISTIVITY DIV 05 : METALS I. ALLOY STEELS: HIGHSTRENGTH LOW-ALLOY STEELS WITH IMPROVED MECHANICAL PROPERTIES AND RESISTANCE TO ATMOSPHERIC CORROSION J. ALLOY STEELS: STAINLESS STEELS CONTAIN MORE THAN 10% CHROMIUM; USED WHERE CORROSION RESISTANCE, DURABILITY, AND MINIMUM OF MAINTENANCE IS NECESSARY 4. COPPER • DUCTILE, MALLEABLE, NONMAGNETIC METAL • BRIGHT, REDDISH BROWN COLOR • HIGHEST ELECTRICAL AND THERMAL CONDUCTIVITY OF ANY SUBSTANCES EXCEPT SILVER • ENOUGH STRENGTH FOR MINOR STRUCTURAL WORK • ATTACKED BY ALKALIS AND MANY OF THE COMMON ACIDS • EASILY WORKED • HIGHLY RESISTANT TO CORROSION BY AIR AND SALT WATER PATINA INSOLUBLE GREEN SALT WHICH RETARDS FURTHER CORROSION 5. TIN • SOFT, DUCTILE, MALLEABLE, BLUISH-WHITE METAL • COVERED WITH A THIN FILM OF STANNIC OXIDE, IT RESISTS CORROSION BY AIR, MOISTURE, SULFUR DIOXIDE, HYDROGEN SULFIDE • HIGHLY REFLECTIVE POLISH • USES OF TIN INCLUDE BRONZES, BRASSES, TERNEPLATE, MIRRORS, GILDING, SOLDERS, HARDWARE AND FUSIBLE ALLOYS 6. ZINC • MEDIUM HARD, BLUISH-WHITE METAL • CHARACTERIZED BY BRITTLENESS AND LOW STRENGTH • READILY ATTACKED BY ACIDS AND ALKALIS • READILY ATTACKED BY ACIDS AND ALKALIS • RESISTANT TO CORROSION BY WATER GALVANIZING THE PROCESS WHEREBY A PROTECTIVE COAT OF ZINC IS APPLIED TO STEEL AND IRON TO PROTECT THEM AGAINST CORROSION 7. BRASS • ALLOY OF COPPER AND ZINC • LESS HARD AND STRONG THAN STEELS BUT ARE SUPERIOR IN WORKABILITY AND RESISTANCE TO CORROSION • REACT WITH OTHER METALS DIV 05 : METALS 8. BRONZE • ALLOY OF COPPER AND TIN • RICH GOLDEN-BROWN METAL • STATUARY BRONZE – ONLY TRU BRONZE • CONFINED TO STATUARY, PLAQUES, MEDALLIONS AND OTHER ORNAMENTATION AND HARDWARE 9. CHROMIUM • STEEL-WHITE METAL • DOES NOT TARNISH IN AIR, RESISTS OXIDIZING AGENTS • NONMAGNETIC AT ORDINARY TEMPERATURES BUT BECOMES MAGNETIC AT 13°F • ALLOYING INGREDIENT IN FERROUS AND NONFERROUS METALLURGY CHROMIUM PLATING MOST COMMONLY ENCOUNTERED USAGE OF THIS MATERIAL IN ARCHITECTURE; ELECTRO DEPOSITED AS A THIN LAYER OF PURE METAL 10. NICKEL • INERT SILVERY METAL • PROTECTIVE OR DECORATIVE COATING FOR OTHER METALS • RESEMBLES IRON IN STRENGTH AND TOUGHNESS AND COPPER IN ITS RESISTANCE TO OXIDATION AND CORROSION 11. LEAD • BLUE-GRAY, SOFT, VERY HEAVY METAL • EXTREMELY WORKABLE, HAS GOOD CORROSION RESISTANCE, IS EASILY RECOVERED FROM SCRAP MATERIALS, AND IS RELATIVELY IMPENETRABLE TO RADIATION ALUMINUM IRON CAST IRON WROUGHT IRON STEEL NICKEL TIN BRONZE COPPER BRASS CHROMIUM LEAD ZINC DIV 05 : METALS DIV 05 : METALS METHODS OF JOINING METAL 1. SOLDERING LOWER MELTING METAL OR ALLOY CALLED THE SOLDER A. METAL BATH DIP A METAL- JOINING PROCESS WHERE THE WORKPIECES TO BE JOINED ARE IMMERSED IN A POT OF MOLTEN SOLDER B. SOLDERING IRON THE IRON PIECE IS PREHEATED ANDAPPLIED TO THE JOINT ALONG WITH THE SOLDER AND THE FLUX C. TORCH PARTS TO BE SOLDERED ARE HEATED BY THE TORCH FLAME AND THEN THE SOLDER AND FLUX ARE APPLIED D. SWEAT METHOD HEATING OF THE METALS TO BE JOINED CAUSES THE SOLDER TO RUN INTO THE JOINT; USED FOR JOINING COPPER TUBING AND FITTINGS 2. BRAZING TYPE OF SOLDERING IN WHICH THE OPERATING TEMPERATURES ARE HIGHER; STRONGER THAN ORDINARY SOLDERED JOINTS 3. WELDING PROCESS BY WHICH TWO METALS ARE SO JOINED THAT THERE IS AN ACTUAL UNION OF THE INTERATOMIC BONDS (a) PRESSURE WELDING - PRESSURE AND HEAT MAKE THE WELD (b) FUSION WELDING - THE HEAT AND ADDED METAL MAKE THE WELD 4. THRU RIVETS USED TO JOIN OR FASTEN THE METALS; METAL CYLINDER OR ROD WHICH HAS A HEAD AT ONE END; PROTRUDING END IS FLATTENED TO TIE THE TWO PIECES OF MATERIAL TOGETHER SOLDERING IRON SWEAT MEATHOD SOLDERING METAL DIP SOLDERING METHODS OF JOINING METALS WELDING DIV 05 : METALS WELDING SYMBOLS & DEFECTS DIV 05 : METALS WELDING SYMBOLS DIV 05 : METALS DIV 05 : METALS DIV 05 : METALS METALS FOR CONCRETE REINFORCEMENT 1. STEEL BARS IN THE FORM OF STEEL BARS AND RODS OF ROUND OR SQUARE CROSS SECTION BILLET-STEEL BARS OR RAIL-STEEL BARS MADE BY THE OPEN HEARTH FURNACE BY THE ACID BESSEMER FURNACE AND MEET FIXED CHEMICAL COMPOSITIONS; THEY ARE ROLLED FROM BILLETS DIRECTLY REDUCED FROM INGOTS 2. WIRE FABRIC MADE OF COLD-DRAWN STEEL WIRE IS WIDELY USED FOR THE REINFORCEMENT OF CONCRETE SLABS AND FLOORS, AS WELL AS FOR STUCCOED WORK A. WELDED WIRE FABRIC USED TO REINFORCE CONCRETE SLABS USED IN LIGHT CONSTRUCTION. B. TRIANGLE-MESH WIRE FABRIC BUILT UP OF EITHER SINGLE OR STRANDED LONGITUDINAL WIRES WITH CROSS WIRES OR BOND-WIRES RUNNING DIAGONALLY ACROSS THE FABRIC 3. EXPANDED MESH MANUFACTURED FROM SOLID STEEL SHEETS; FREE FROM MECHANICAL AND WELDED JOINTS 4. LATHS FURNISHED EITHER IN FLAT OR SEGMENTAL SHEETS, PRESSED INTO A SERIES OF SOLID RIBS, BETWEEN WHICH THE METAL IS STAMPED, PERFORATED OR DEFORMED INTO AN OPEN MESH-WORK STORAGE & CARE FOR METAL REINFORCEMENT • STORED IN RACKS ABOVE THE GROUND AND AWAY FROM MOISTURE AND VEGETATION • SHOULD BE KEPT FREE FROM OIL WHICH WILL TEND TO REDUCE THE BOND BETWEEN CONCRETE AND STEEL rebars commercially available pre-order 6.00 m 13.50 m 7.50 m 15.00 m 9.00 m 10.50 m 12.00 m rebar sizes weight 10 mm dia. 3/8” no. 1 0.617 kg/m 12 mm dia. 4/8” or ½” no. 2 0.888 kg/m 16 mm dia. 5/8” no. 3 1.58 kg/m 20 mm dia. 6/8” or 3/4” no.4 25 mm dia. 8/8” or 1” no. 5 DIV 05 : METALS WELDED BOLT/RIVET COMBINATION AISC AMERICAN INSTITUTE OF STEEL CONSTRUCTION ACI AMERICAN CONCRETE INSTITUTE DOG BONE TAB DIV 05 : METALS DIV 05 : METALS FORMING METALS ROLLING USING ROTATING ROLLS FORGING BY MEANS OF PRESSURE OR IMPACT BLOWS DRAWING PULLING A WORKPIECE THROUGH A DIE STAMPING MACHINE PRESS OR STAMPING PRESS EXTRUSION FORCING TO FLOW THROUGH A SHAPED OPENING IN A DIE CASTING/ MOLDING POURING LIQUID METAL T A MOLD DIV 05 : METALS W 10 X 33 33 LBS CONCRETE PLASTER GYPSUM SPRAY APPLIED INSULATION WATER FILLED COLUMNS LOOSE INSULATION WITHIN SHEET METAL COLUMN COVER DIV 05 : METALS DIV 05 : METALS PARTS OF SPACE FRAME DIV 05 : METALS DIV 05 : METALS – SPACE FRAME DIV 05 : METALS – FABRIC STRUCTURE/ TENSILE STRUCTURE DIV 05 : METALS – FABRIC STRUCTURE/ TENSILE STRUCTURE CLASSIFICATION OF LUMBER STRIPS LESS THAN 2” THK AND LESS THAN 8” WIDE BOARD LESS THAN 2” THK AND AT LEAST 8” WIDE DIMENSION LUMBER MORE THAN 2” AND LESS THAN 5” IN ANY DIMENSION TIMBERS 5” OR MORE ON THE SMALLEST DIMENSION MEASUREMENT OF LUMBER NOMINAL SIZE ACTUAL SIZE 1 x 2 3/4 x 1 1/2 inches (19 x 38 mm) 1 x 3 3/4 x 2 1/2 inches (19 x 64 mm) 1 x 4 3/4 x 3 1/2 inches (19 x 89 mm) 1 x 5 3/4 x 4 1/2 inches (19 x 114 mm) 1 x 6 3/4 x 5 1/2 inches (19 x 140 mm) 1 x 8 3/4 x 7 1/4 inches (19 x 184 mm) 1 x 10 3/4 x 9 1/4 inches (19 x 235 mm) 1 x 12 3/4 x 11 1/4 inches (19 x 286 mm) 2 x 2 1 1/2 x 1 1/2 inches (38 x 38 mm) 2 x 3 1 1/2 x 2 1/2 inches (38 x 64 mm) 2 x 4 1 1/2 x 3 1/2 inches (38 x 89 mm) 2 x 6 1 1/2 x 5 1/2 inches (38 x 140 mm) 2 x 8 1 1/2 x 7 1/4 inches (38 x 184 mm) 2 x 10 1 1/2 x 9 1/4 inches (38 x 235 mm) 2 x 12 1 1/2 x 11 1/4 inches (38 x 286 mm) 4 x 4 3 1/2 x 3 1/2 inches (89 x 89 mm) 4 x 6 3 1/2 x 5 1/2 inches (89 x 140 mm) 6 x 6 5 1/2 x 5 12 inches (140 x 140 mm) DIV 06 : WOODS AND PLASTICS TERM DEFINITION SOFTWOOD FROM CONIFERS HARDWOOD FROM BROAD-LEAVED OR DECIDUOUS TREES SAPWOOD SOFTER, YOUNGER, OUTER PORTION OF A TREE HEARTWOOD OLDER, HARDER CENTRAL PORTION OF TREE KNOTS WANE PITCHPOCKETS WOOD DEFECTS DIV 06 : WOODS AND PLASTICS SHAKES WARPING CHECKS - CRACKS OR LENGTHWISE SEPERATION ACROSS THE ANNUAL RINGS OF GROWTH CAUSED BY IRREGULAR SHRINKAGE DURING DRYING WANE - LACK OF WOOD AT THE EDGE OR CORNER OF A PIECE DECAY DIV 06 : WOODS AND PLASTICS DIV 06 : WOODS AND PLASTICS WOOD PLASTIC COMPOSITE WOOD FOAM DIV 06 : WOODS AND PLASTICS WOOD COMPOSITES DIV 06 : WOODS AND PLASTICS WOOD JOINTS DIV 06 : WOODS AND PLASTICS DIV 06 : WOODS AND PLASTICS TYPES OF SIDING DIV 06 : WOODS AND PLASTICS THERMOPLASTICS SOFT WHEN HEATED, HARD WHEN COOLED THERMOSETTING SET TO SHAPE PERMANENTLY ARCRYLIC MELAMINE & UREA CELLULOSICS EPOXY POLYETHYLINE ALKYDS POLYSTYRENE PHENOLICS POLYVINYL CHLORIDE (PVC) POLYESTER POLYCARBONATES URETHANES POLYPROPYLENE SILICONES NYLONS POLYURETHANE FLOUROPLASTICSACRYLONITRILE BUTADIENE STYRENE (ABS) POLYURETHANE DIV 06 : WOODS AND PLASTICS LIQUID WATERPROOFING MEMBRANE BITUMINOUS MEMBRANE WATERPROOFING METHOD BITUMINOUS COATING WATERPROOFING METHOD 1. IMPERMEABLE THROUGH A DENSE CONCRETE 2. WATERPROOFING COATINGS AND WASHES 3. INTEGRAL WATERPROOFING COMPOUNDS -SAHARA -POZZOLITH -AQUELLA -SILICON -ANTI HYDRO 4. MEMBRANE WATERPROOFING POLYURETHANE WATERPROOFING CEMENTITIOUS WATERPROOFING DIV 07 : THERMAL AND MOISTURE PROTECTION DIV 07 : THERMAL AND MOISTURE PROTECTION TYPES OF SEALANT: - BITUMINUOUS CEMENT - SILICONE SEALANT ROOFING PITCH ANOTHER TERM FOR ROOF SLOPE 26 USUAL GAUGE OF LONG SPAN ASPHALT SHINGLES USES MARINE PLYWOOD UNDERSHEATHING; HAS 15 YRS WARRANTY; 1/8 “ GAP PROVIDED FOR SEASONAL EXPANSION WHEN INSTALLING THE ROOF SHEATING CLEAT USE TO SUPPORT PURLINS ON A WOODEN ROOF FRAME PURLINS LONGITUDINAL MEMEBERS ON TOP OF CHORDS SUPPORTING THE ROOF FERNANDO P. JACINTO FATHER OF THE PHILIPPINE STEEL INDUSTRY JACINTO STEEL PIONEER MANUFACTURER OF GI SHEETS JACINTO COLOR STEEL INC. CURRENT CORPORATE NAME OF JACINTO STEEL 32” STANDARD WIDTH O`F CORRUGATED GI SHEET DRIP MOLD USED FOR SHEDDING WATER SO AS TO KEEP IT FROM RUNNING DOWN ON A WALL OR FROM ENTERING A SILL SCUPPER OPENING IN A WALL OR PARAPET THAT ALLOWS WATER TO DRAIN FROM A ROOF AREA DRAIN RECEPTACLE DESIGNED TO COLLECT SURFACE WATER OR STORM WATER FROM AN OPEN PARKING AREA ROOF LEADER PIPE INSTALLED TO DRAIN WATER FROM THE ROOF GUTTER 6.00 M – 12.00 M MOST COMMON ROOFING SIZE 25 CM MIN. END LAPPING FOR DORRUGATED GI ROOFING 1 ½” MIN. SIDE LAPPING FOR DORRUGATED GI ROOFING INFINITE MAX. LENGTH OF GI SHEET SAG ROD PREVENTS MOVEMENT OF PURLINS TURNBUCKLE PREVENTS MOVEMENT OF TRUSS ROOFING 50 X 200 MM MEASUREMENT OF RAFTER 50 X 100 MM MEASUREMENT OF COLLAR PLATE 50 X 50 MM MEASUREMENT OF WEB MEMBER 50 X 75 MM MEASUREMENT OF PURLINS ROOFING BRICK SLATE CONCRETE POLYCARBONATED GALVANIZED IRON (MIN. 3% SLOPE) ALUMINUM TAR/ ASPHALT SHINGLES (15 YRS WARRANTY) WOOD SHINGLES BITUMEN PVC PLASTISOL POLYESTER PAINTED SHEETS COPPER DIV 07 : THERMAL AND MOISTURE PROTECTION DIV 07 : THERMAL AND MOISTURE PROTECTION DIV 07 : THERMAL AND MOISTURE PROTECTION DIV 07 : THERMAL AND MOISTURE PROTECTION DIV 08 : DOORS AND WINDOWS DIV 08 : DOORS AND WINDOWS DIV 08 : DOORS AND WINDOWS DIV 08 : DOORS AND WINDOWS DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES DIV 09 : FINISHES TYPES OF NAILS WROUGHT HEAD NAIL (FROM ROMANS) DIV 09 : FINISHES BLIND RIVET SPEEDY RIVET DIV 09 : FINISHES ESCUTCHEON BOTTOM MOUNT DRAWER SLIDE CENTER MOUNT DRAWER SLIDE BALL BEARING DRAWER SLIDES SOFT CLOSE BALL BEARING DRAWER SLIDES DRAWER SLIDES/ DRAWER GUIDE DIV 09 : FINISHES DIV 09 : FINISHES BUTT/ MORTISE HINGE PIANO HINGE PIVOT HINGE BUTTERFLY HINGE BI-FOLD/ FLUSH HINGE BARREL HINGE EUROPHEAN HINGE GATE HINGE STRAP HINGE SPRING HINGE LOOSE PIN/CASE HINGE FLAG HINGE CONCEALED HINGE FLAG HINGE LATCH HINGE OFF-SET HINGE WELD-ON HINGE DOUBLE ACTION HINGE SLIP JOINT HINGE PARLIAMENT/ H HINGE OLIVE KNUCKLE/ PAUMELLE HINGE CROSS GARNET/ T HINGE LOOSE JOINT HINGE GRAVITY HINGE RISING HINGE INVISIBLE HINGE DIV 09 : FINISHES DIV 09 : FINISHES TSA APPROVE LOCK KEY BASED PADLOCK COMBINATION PADLOCK PADLOCK LOCKABLE THUMBTURN STYLE JIMMY PROOF DEADBOLTS DOUBLE CYLINDER DEADBOLTS SINGLE CYLINDER DEADBOLTS KNOB LOCKS LEVER HANDLE LOCKS VENDING/ T-HANDLE LOCKS DEADBOLT LOCK HANDLE OTHER CYLINDER MORTISE/RIM CYLINDER LOCKS INTERCHANGEABLE CORE CYLINDERS RIM LATCH LOCKS KEY IN KNOB (KIK) CYLINDERS SINGLE EURO PROFILE CYLINDER PUSH BUTTON STYLE FURNITURE LOCKS DOUBLE EURO PROFILE CYLINDER DOUBLE EURO PROFILE CYLINDER EURO PROFILE CYLINDERS PUSH BUTTON STYLE FURNITURE LOCKS BOLT STYLE FURNITURE LOCKS FURNITURE LOCKS ELECTRONIC (DIGITAL) LOCKS SMART LOCKS DIV 09 : FINISHES ELECTROMAGNETIC OVERHEAD TRANSOM FLOOR SPRING DOOR CLOSER SLIDE ARM CONCEALED DOOR STOPPER DIV 09 : FINISHES LATCHES DIV 09 : FINISHES DIV 09 : FINISHES CONCRETE SURFACE FINISHES SCRATCH COAT TROWELLED ONTO THE WALL SURFACE; JUST AS SOON AS THE FIRST COAT IS BUT NOT HARD, IT IS SCRATCHED W/ A SMALL RAKE TO FORM A KEY FOR THE SECOND COAT. 3/8” THK BROWN COAT APPLIED A FEW DAYS AFTER THE FIRST COAT HAD SET HARD; APPLIED WITH A WOOD FLOAT` AND LEVEL TO A FLAT , EVEN AND SMOOTH SURFACE. 3/8” THK FINISH COAT APPLIED OVER THE BROWN COAT AFTER ALL WORK IS FREE FROM WAVES AND CRACKS, AND SET AND DRY; SHOULD BE KEPT DAMP BUT NOT WET FOR A FEW DAYS TO AVOID HAIRLINE CRACKS. 1/8” - 1/4” THK EXPOSED AGGREGATES • DRY-SHAKE FINISH • BETON BRUT • BROOM FINISH • SWIRL FINISH • BUSHHAMMERED FINISH DIV 09 : FINISHES NO OF TILES IN A BOX 20X30 25 PCS 30X30 11 PCS 40X40 9 PCS 60X60 4 PCS 30X60 4 PCS 80X80 2 PCS 100X100 1-2 PCS VINYL TILE 30X30 45 PCS 40X40 45 PCS CORK TILE 30X30 30X60 PLANKS 30X90 LINOLEUM SHEET 20FTX6FTX30FT TILE 9X9 RUBBER SHEET 30X120 TILE 30X30 60X60 90X90 VINYL TILE 30X30 40X40 SHEET 6FTX12FT DIV 09 : FINISHES TYPES OF TERRAZZO VENETIAN STANDARD RUSTIC PALLADIANA DIV 09 : FINISHES CEMENT TILE/ MACHUCA • 25 MM / 1” THICKNESS • COMMON SIZES (SQUARES) • 200X200 MM (8”X8”) • 300X300 MM (12”X12”) • 400X400 MM (16”X16”) QUARRY TILES ASPHALT TILE VINYL TILE RUBBER TILE LINOLEUM SHEET DIV 09 : FINISHES CARPET DIV 09 : FINISHES TYPES OF PARQUET NUMBERS ARRANGED FROM STRENGTH DIV 09 : FINISHES PATTERNED GLASS OBSCURE GLASS SPANDREL GLASS REFLECTIVE GLASS TINTED GLASS INSULATING GLASS BACKPAINTED GLASS BACKPAINTED GLASS DIV 09 : FINISHES PAVEMENTS - NUMBERS ARRANGED FROM MOST SUITABLE FOR VIBRATION DIV 09 : FINISHES NUMBERS ARRANGED FROM CHEAPEST TO EXPENSIVE DIV 09 : FINISHES DIV 09 : FINISHES PAINT CONVERSIONS 1 GALLONS 8 PINTS 1 PAIL 4 GALLONS 1 GALLONS 4 LITERS 1 GALLONS 30 SQM COVERAGE 1 PERSON 15 SQM/ HR 1 PERSON 120 SQM/ DAY PAINTS QUICK DRY ENAMEL (QDE) WOOD AND METAL PERMACOAT EXCELLENT ADHESION; MASONRY WOODS & MET ALS LATEX PAINT CONCRETE ACRYLIC LATEX MOST DURABLE & FLEXIBLE (EXTERIOR & INTERIOR) ELASTOMERIC PAINT BEST FOR WATERPROOFING WALLS AND FLOORS BOYSEN ACQUA EPOXY PAINT USED ON SWIMMING POOLS COMPOSITIONS EMULSION LIKE A PAINT ALKYD VEHICLE FOOR THE PIGMENT SOLVENT MAINTAINING LIQUID Latex • Water-based • Easy to clean up • Adheres to most substrates • Paintable • Less expensive than other sealants • Best suited for interior finish applications, where gaps are small and movement is minimal • Prone to shrinkage Acrylic • Solvent based • Paintable • More difficult application compared with latex • Uv stable • Not prone to shrinkage • Used in commercial and exterior applications • Low to moderate cost • Limited movement capability Polysulfide • Water resistant • Chemical resistant • UV resistant • Flexible even at low temperatures with little shrinkage • Requires primer • Used in swimming pools or other underwater applications • May have higher levels of VOCs • Long life expectancy, 10 to 20 years • High cost Silicone • UV resistance • Thermal resistance • Highest movement capability • Good adhesion • Long service life • Flexibility • Long curation time • Strong odor • Used in glass assemblies • High cost • Not paintable • Can produce staining to certain substrates Butyl • Solvent based • Strong adhesion to multiple substrates • Poor abrasion resistance • Difficult application • Limited movement capability • Used in curtain wall systems, where adhesion to rubber materials is needed • Moderate cost Polyurethane • Abrasion resistant • Can be painted • Adhere well to different surfaces with little substrate preparation • High movement capability • Durable • Difficult application and tooling • Cannot be used in glass assemblies • High cost Polyisobutylene • Durable • Chemical resistant • Low permeability • Used as the primary seal for insulating glazing units • Products are usually factory applied, not on site DIV 09 : FINISHES DIV 09 : FINISHES RUNNING/ SAGGING STORM SPOTTING STAIN ALLIGATORING CRACKING & SCALING BLISTERING WRINKLING BLOOMING FLASHING BLOCKING BRUSH/ROLLER MARKS CHALKING DEFLORESCENCE FADING YELLOWING DIV 09 : FINISHES PAINT DEFFECTS HOT AIR SPRAY AIRLESS SPRAY COLD AIR SPRAY BRUSHING ROLLERS DIPPING AEROSOL APPLICATOR PAD PAINT APPLICATION DIV 09 : FINISHES FLOW COATING FLUIDIZED BED CURTAIN COATING MACHINE ROLLER COATING ELECTRODEPOSITION COATING DIV 09 : FINISHES PAINT APPLICATION PRY BAR FOLDING RULER DIGITAL RULER PLUMB BOB SPIRIT LEVEL MITER SQUARE - 45° PLASTER GROUND TAPE MEASURE NAIL SET BLIND RIVETER SHOVEL FRAMING SQUARE/ STEEL SQUARE CHALK LINE TOOLS & EQUIPMENT TOOLS & EQUIPMENT SPIRAL RATCHET SCREWDRIVER (PUSHING FORCE) TOOLS & EQUIPMENT BACK SAW COPING SAW CROSSCUT SAW HACK SAW JAPANESE SAW KEY HOLE SAW POLE SAW PRUNING SAW RIP CUT SAW WALLBOARD SAW BAND SAW PORTABLE BAND SAW CHAIN SAW CHOP SAW FLOOR SAW JIGSAW VENEER SAW BOW SAW TRACK SAW FRET SAW TILE SAW TABLE SAW FRAME SAW OSCILLATING SAW CIRCULAR SAW TOOLS & EQUIPMENT TOOLS & EQUIPMENT TOOLS & EQUIPMENT BULL FOAT OTHERS DRAPERY POCKET OTHERS CRANK GEAR GONDOLA RACK GONDOLA WINDOW STAY HOLE AND PEG/ COLONIAL WINDOW STAY (FOR STORMY WEATHER) ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES ESTIMATES OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) CONVECTION WHEN WARM AIR IN A ROOM RISES AND FORCES THE COOLER AIR DOWN BARRIER SYSTEM WALL SYSTEM THAT IS INTENDED TO MANAGE ALL WATER AT THE EXTERIOR SURFACE SYMBOL “R” INSULATING MATERIALS TITANIUM OXIDE MOST IMPORTANT PIGMENT; WHITE IN COLOR AND USED TO PROVIDE HIDING IN PAINT MORTAR A SUBSTANCE USED TO JOIN MASONRYY UNITS CONSISTING OF CEMENTITIOUS MATERIALS, FINE AGGREGATE AND WATER SHELF ANGLE A CONVENIENT SUPPORT MEMBER ATTACHED TO THE BEAM TO BEAR THE LOAD OF THE MASONRY WALL BALLAST TERM FOR A MATERIAL INSTALLED OOVER A ROOF MEMBRANE TO PREVENT WIND UPLIFT AND SHIELD THE MEMBRANE FROM SUNLIGHT • ARTIFICIAL LIGHTIHNG IS ABOUT HALF AS EFFICIENT AS NATURAL LIGHTING CURTAIN BOARD VERTICAL PANEL OF NON-COMBUSTIBLE MATERIAL ATTACHED TO AND EXTENDING BELLOW THE BOTTOM CHORD OF THE ROOF TRUSSES, TO DIVIDE THE UNDERSIDE OF THE ROOF INTO SEPARATE COMPARTMENTS SO THAT THE HEAT AND SMOKE WILL BE DIRECTED UPWARDS TO A ROOM VENT. SAFING TERM FOR A FIRE RESISTAANT MATERIAL INSERTED INTO A SPACE TOO RETARD THE PASSAGE OF FIRE THRU A SPACE TENDON USED FOR PRESTRESSING A CONCRETE MEMBER SLEEPER WOODEN STRIPS LAID UPON A CONCRETE SLAB TO PROVIDE A MEANS OF ATTACHING WOOD FLOORS SUMP A PIT DESIGNED TO COLLECT WATER FOR REMOVAL FROM AN EXCAVATION ANCHOR BLOCKS LARGE OR HEAVY OBJECT BURIED IN THE GROUND AS AN ANCHOR CASTELLATED BEAM A STEEL BEAM FABRICATED BY THE DIVIDING THE WEB OF A WIDE-FLANGE SECTION WITH A LENGTHWISE ZIGZAG CUT, THEN WELDING BOTH HALVES TOGETHER AT THE PEAKS, THUS INCREASING ITS DEPTH WITHOUT INCREASING ITS WEIGHT OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) BLOWER DOOR EQUIPMENT THAT TESTS AIR LEAKAGE DOOR CLEARANCE THE MARGIN CLEARANCE AROUND THE EDGE OF A DOOR, BETWEEN DOOR AND FRAME IRON DOG A HEAVY U-SHAPED STAPLE USED TO TIE THE ENDS OF HEAVY TIMBERS TOGETHER CONTROL JOINT A CONCRETE SURFACE HARDENS BEFORE THE NEXT BATCH OF CONCRETE IS PLACED AGAINST IT LOUVERS WITH 150MM WITH BLADES ADMITS 95% OF AIR SOLAR TINT A "NEW MATERIAL" USE TO BLOCK EXCESSIVE SUNLIGHT SLIDING WINDOW THAT IS EASIEST TO CLEAN STUDS FOR WALL FRAMING FURRING FOR CEILING FRAMING JOIST FOR FLOOR FRAMING SILO FOR SLIP FORM PUTTY APPLY LAST BEFORE PAINTING IF WOOD OR GYPSUM BOARD NEUTRALIZER APPLY LAST BEFORE PAINTING IF CONCRETE PERMATEX HAS GEL/ RUBBER FINISH SHOP COAT TERM USED FOR THE INITIAL COAT ON STRUCTURAL STEEL FROM THE FACTORY PRIOR TO ITS SHIPMENT ANODIZING INTEGRATED ON METAL POWDER COATING "COATED" ON METAL 1:16 RATIO OF NEUTRALIZER TO WATER LACQUER BASED BEST PRIMER FOR ENAMEL PAINT TURPENTINE BEST THINNER FOR ENAMEL PAINT 5 M AFTER REACHING THE HARD STRATA MIN DEPTH IF SOIL BORING TEST 120MFROMCONSTRUCTIONLINESTARTOFEXCAVATION OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) TEGULA 15 YRS WARRANTY 2 - 3% MIN, SLOPE FOR GI ROOF 0.80 M - 1.00 M WIDTH OF GI LONGSPAN ALUMINUM AND COPPER TWO METALS THAT SHOULD NOT BE COMBINED STAPLE WIRE NAILS USED FOR ASPHALT SHINGLES DRIP MOULD USE FOR SHEDDING RAINWATER TO KEEP IT FROM RUNNING DOWN A WALL OR FROM ENTERING A SILL SCUPPER DRAIN/ WEEP HOLE OPENING IN A WALL OR PARAPET THAT ALLOWAS WATER TO DRSIN FROM A ROOF AREA DRAIN RECEPTOR DESIGNED TO COLLECT SURFACE WATER OR STORM WATER FROM AN OPEN PARKING AREA ROOF LEADER/ DOWNSPOUT INSTALLED TO DRAIN WATER FROM A GUTTER 25 CM MIN END LAPPING FOR CORRUGATED GI ROOFING 1 1/2" - 2 1/2" MIN SIDE LAPPING FOR CORRUGATED GI ROOFING 0.30 M / 12" SMALLEST GUTTER SIZE L-FLASHING USE WHEN THE TOP OF THE ROOF BUTTS THE WALL STEP FLASHING USE WHEN THE SIDE OF THE ROO BUTTS THE WALL GALVANIZED ZINC COATED IN TWO SIDES FASCIA BOARD WHERE THE GUTTER IS ATTACHED VULCASEAL HOW TO JOIN GUTTERS TEGULA 15 YRS WARRANTY 2 - 3% MIN, SLOPE FOR GI ROOF 0.80 M - 1.00 M WIDTH OF GI LONGSPAN ALUMINUM AND COPPER TWO METALS THAT SHOULD NOT BE COMBINED STAPLE WIRE NAILS USED FOR ASPHALT SHINGLES DRIP MOULD USE FOR SHEDDING RAINWATER TO KEEP IT FROM RUNNING DOWN A WALL ORFROMENTERINGASILL OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) BOLTED TRUSS CONNECTION THAT IS EASILY RECYCLABLE CURVILINEAR GI ROOF ROOF IDEAL FOR SIDEWALK HEEL JOINT OF THE TRUSS WHERE THE TOP AND BOTTOM CHORD MEETS DIAMOND TIP CUTTER USE TO CUT GLASS FLOAT TYPE OF GLASS WITH MINIMAL DISTORTION ARGON/ ORDINARY ARC A DOUBLE INSULATING GLASS HAVE THAT IS ABLE TO LET SHORT WAVELENGTHS THROUGH SUCH AS LIGHT BUT BLOCKS LONG WAVELENGTHS SUCH AS ULTRAVIOLET HEAT OBSCURE GLASS GLASS HAVING ONE OR BOTH SIDES ACID-ETCHED OR SANDBLASTED TO OBSCURE VISION ETCHED GLASS GLASS WHERE ART IS CREATED BY APPLYING ACID TO IT FIGURE GLASS / PATTERN GLASS GLASS HAVING AN IRREGULAR SURFACE PATTERN FORMED IN THE ROLLING PROCESS TO OBSCURE VISION GLAZING BEAD USE TO HOLD GLASS PANE IN PLACE CYLINDER / CROWN GLASS TYPE OF GLASS WITH THE WAVIEST FACE ANODIZED WINDOW FRAME FINISH THEN INSTALL FRAME STEEL WINDOW FRAME INSTALL FRAME THEN FINISH 1.60 M MAX WIDTH OF SLIDING WINDOW FRAME RAIL TERM USED IN HORIZONTAL PART OF A DOOR STILE TERM USED IN VERTICAL PART OF A DOOR BACKSET HORIZONTAL DISTACE FROM THE FACE OF A LOCK OR LATCH TO THE CENTER OF THE KEYHOLE, KNOB OR BLOCK CYLINDER LOOSE PIN HINGE HINGE WITH REMOVABLE PIN PIVOT/ FLOOR CHECK HINGE USED FOR FRAMELESS GLASS DOOR STYROPORE FILLER OF A FLUSH DOOR KALAMEIN FIREPROOF DOOR WITH METAL COVERING OVOLOMOULDINGUSEDTOAVOIDTERMINATION OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) BOLTED TRUSS CONNECTION THAT IS EASILY RECYCLABLE ROUGH LUMBER UNDRESSED LUMBER NEWEL POST SUPPORTING ONE END OF A HANDRAIL AT THE TOP OR BOTTOM OF A FLIGHT OF STAIRS NEWEL CAP/ FINIAL TERMINAL FEATURE OF A NEWEL POST CURTAIL STEP THE STEP AT THE FOOT OF A FLIGHT OF STAIRS WIDENED AT ONE OR BOTH ENDS COMMON YARD LUMBER KIND OF WOOD THAT HAS A LOT OF KNOT SELECT YARD LUMBER KIND OF WOOD THAT HAS NO KNOT MATWOOD WOOD PRODUCT WITH SOLIGNUM BORAX AN ORGANIC, NON-TOXIC TREATMENT FOR WOOD AGAINST TERMITES AND OTHER INSECTS RIGID FRAMES FORM AKA PORTAL FRAME COLD ROLLING IF METAL IS ROLLED BELOW ITS RECRYSTALLIZATION TEMPERATURE CAULKING ACT OF PLUGGING AN OPENING WITH OAKUM, LEAD 28 DAYS CURING OF CONCRETE SHOTCRETE WET PROCESS GUNITE DRY PROCESS HEX BOLTS SHEAR CONNECTORS 2" MAX SLUMBS FOR SLABS, BEAMS AND COLUMNS ASSEMBLY THE PROCESS OF TRANSFERING AND RECONSTRUCTION OF PARTS ON SITE L/4 BEST LOCATION OF A SLEEVE OPENING IN A RC BEAM 6-8 CU.M. READY MIX CONCRETE 0.10 - 0.15 M RISE OF SLAB FROM THE LEDGE SAND-GRAVEL-CEMENT-WATER PROPER SEQUENCE IN MIXING CONCRETE SHS METAL TUBES STRUCTURAL HOLLOW SECTION CHSMETALTUBESCIRCULARHOLLOWSECTION OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) SLEEPER FLOORING NAILER WALL/ CEILING LATH & PLASTER USED TO ADHERE CONCRETE PLASTER ON THE SURFACE OF A PLYWOOD WALL FLAGSTONE MATERIAL USED FOR GARDEN WALL THAT IS EASILY BROKEN BY HAND POLYMER HARDENED MIXTURE MIXED WITH DUST TO FILL-UP GAPS IN MARBLE AND WALL FINISHES DIAGONAL BRACING USED TO STABILIZE UNSTABLE FORMS SHORING USE TO SUPPORT UNSTABLE FORMS STRIPPING TERM FOR REMOVAL OF FORMS JACKBILT LEADING MANUFACTURER OF LOAD BEARING CHB IN PH BLINDING/ LEAN CONCRETE THE CONCRETE WERE THE FOUNDATION RESTS LEAN CONCRETE CONCRETE WITH NO REINFORCEMENT TYROLEAN FINISH ROUGH PLASTER FINISH OBTAINED BY FLINGING ON THE WALL NOTCH TROWEL USED TO APPLY TILE ADHESIVES SPLASHBOARD AKA WEATHER BOARD SCAFFOLDING CARRIES HUMAN WORKERS AND MATERIALS SHORING CARRIES THE STRUCTURE (BEAMS, SLABS, ETC.) FORMWORK AKA SHORING DECK 10 FEET HEIGHT OF SCAFFOLDING PLATFORMS THAT REQUIRES A FALL PROTECTION 1:2 RISE:RUN MAX SLOPE OF CUT AND FILL LATHE OR TORNO MACHINE USED TO MAKE ROUND WOODEN BALLUSTERS JIGSAW USE FOR CUTTING CURVES ON THIN PLYWOOD ROUTER USE TO CUT WOODEN BALUSTERS TO ITS CURVED SHAPE WING SCREW USED ON GUTTERS TEK SCREW SELF TAPPING SCREW OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) ANCHOR BOLT WOOD TO MASONRY; PEDESTAL CONCRETE TO COLUMN STEEL V-GROOVE STEEL TO STEEL; TYPE OF WELD SELF TAPPING SCREW LIGHT GAUGE METAL TO LIGHT GAUGE METAL YAKAL TYPE OF WOOD USED FOR POST OR GITDER ATTACHED TO CONCRETE ANCHOR BOLT USE TO CONNECT STEEL COLUMN TO A BASE PLATE GTAW/ TIG (TUNGSTEN INERT GAS) WELDING CAN FUSE MATERIALS WITHOUT USING FILLER MATERIALS COLUMN BARRIER AKA COLUMN GUARD GANG NAIL STEEL PLATE WITH A COLLECTION OF SPIKES PROJECTING FROM ONE ANOTHER 1 GAL 8 PINTS; 4 LITERS; 30 SQM COVERAGE 1 PAIL 4 GAL 2"X6" RAFTER 2"X4" COLLAR PLATE 2"X4" WEB MEMBER 2"X4" PURLINS 5 YRS WARRANTY OF WATERPROOFING 25-50 YRS WARRANTY OF SHINGLES 40,000 KG 40 TON TRUCK 2.2 LBS 1 KG COLD DECK BOT TO TOP: INSULATION-DECK-MEMBRANE WARM DECK (USED HERE IN PH) BOT TO TOP: MEMBRANE-INSULATION-DECK INVERTED DECK BOT TO TOP: INSULATION-MEMBRANE-DECK SOFTWOODS ONE BEARING; USED ON WALLS, CEILINGS & FLOORS HARDWOODS LEAF BEARING; USED ON DOORS, FURNITURE & WOOD FRAMES 2% FLAT ROOF OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) S1S SURFACED ON ONE SIDE S2S SURFACED ON 2 SIDES S4S SURFACED OF 4 SIDES YARD LUMER LIGHT CONSTRUCTION & FINISHING WORKS SHOP LUMBER W/ KNOTS & DEFECTS; USED ON SASH, DOORS & CABINETS STRUCTURAL LUMBER HEAVY CONSTRUCTION BOARD LUMBER <2” THK, <=8” WIDE DIMENSION LUMBER <=2” THK, <5” THK/WIDE TIMBER >=5” SMALLEST DIMENSION GRADE A (WOOD) NO DEFECTS OR BLEMISHES GRADE B (WOOD) MINOR DEFECTS & BLEMISHES GRADE C (WOOD) MORE DEFECTS & BLEMISHES THAN B GRADE D (WOOD) MORE DEFECTS & BLEMISHES THAN C STICK SYSTEM ASSEMBLED IN PLACEON THE BLDG UNIT SYSTEM CONSISTING ENTIRELY OF PREFABRICATED PANEL 25 KG/BAG TILE ADHESIVE 4-6 SQM FLOOR TILE ADHESIVE COVERAGE 6-8 SQM WALL TILE ADHESIVE COVERAGE 2400 KG/M³ CONCRETE 7850 KG/M³ STEEL 30LBS/FT³ WOOD 1500 KG/M³ CEMENT 1600 KG/M³ SOIL 1950 KG/M³ SAND 2000 KG/M³ GRAVEL OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) ASTM A36 CARBON STRUCTURAL STEEL ASTM A6 ROLLED STRUCTURAL STEEL BARS, PLATES, SHAPES AND SHEET PILING ASTM A325 STRUCTURAL BOLTS, STEEL, HEAT TREATED ASTM C331 AGGREGATES USED IN CONCRETE MASONRY UNITS ABLATIVE ORGANIC MATERIAL; TURNS TO ASHES ENDOTHERMIC TIME SPENT AND DISAPPEAR INTUMESCENT SWELL AND INCREASE IN VOLUME VERMICULITE THICK LAYERS, AESTHETICALLY UNPLEASING AISC TYPE 1 RIGID -- MOMENT/RESTRAIN (WELDED) AISC TYPE 2 NON-RIGID -- SHEAR/NON-RESTRAIN (BOLT/ RIVET) AISC TYPE 3 SEMI-RIGID -- PARTIALLY RESTRAIN (COMBINATION) 3 MM DOUBLE STRENGTH GLASS 2.5 MM SINGLE STRENGTH GLASS JOINERY ART OR CRAFT OF FORMING JOINTS CYMA REVERSA BEST FOR CEILING CORNERS BUTT JOINT WEAKEST AND SIMPLEST JOINT DRESSED WOOD REFERS TO NOMINAL DIMENSION OF WOOD ROUGH LUMBER UNDRESSED LUMBER SHIPLAP JOINT USED IN FLOORING MILLWORK BLDG PRODUCTS MADE OF WOOD THAT ARE PRODUCED IN THE PLANING MILL SUCH AS MOLDING S, DOORS, AND WINDOW FRAMES, DOOR, WINDOWS, BLINDS AND STAIRS HEX BOLT SHEAR CONNECTORS 2” ALLOWABLE SLUMP IN COLUMNS, BEAMS AND SLABS ASSEMBLY TRANSFERRING AND RECONSRTUCTION OF PARTS ON THE SITE OVERHANGING BEAM SIMPLE BEAM EXTENDING BEYOND ITS SUPPORT AT ONE END CONTINUOUS BEAM BEAM EXTENDDING OVER MORE THAN 2 SUPPORTS L/4 BEST LOCATION OF AA SLEEVE OPENING IN A RC BEAM HYDRATION WHEN WATER IS ADDED TO CEMENT, SEVERAL CHEMICAL REACTIONS OCCUR THAT CAUSES THE FORMATION OF CEMENT PASTE WHICH WILL HARDEN OR BECOME SOLID OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) CHB AKA CMU - CONCRETE MASONRY UNIT SMOKE CHAMBER ENLARGED AREA BETWEEN THE THROAT AND CHIMNEY OF A FIREPLACE TROMBE WALL PASSIVE SOLAR TECHNIQUE WHERE A WALL IS BUILT WITH A GLASS EXTERNAL LAYER TO ABSORB HEAT DURING SUNLIT HOURS AND THEN SLOWLY RELEASES THE HEAT AT NIGHT EIFS EXTERIOR INSULATION FINISHING SYSTEM HYDRAULIC CEMENT TYPE OF CEMENT THAT SETS AND HARDENS WHEN COMBINED WITH WATER FINE SAND PASS THRU NO.40 SIEVE BUT RETAINED ON A NO. 200 COARSE SAND PASS THRU NO. 10 SIEVE BUT RETAINED ON A NO. 40 GRAVEL PASS THRU A 3” SIVE BUT RETAINED ON A NO. 10 SILT CLAY PASS THRU NO. 200 SIEVE FORMS AKA SHUTTER 1% OF SPAN CAMBER OF A BEAM DIAGONAL BRACING STABILIZE UNSTABLE FORMWORKS 1 DAY ALLOWED STEPPING ON A CONCRETE SLAB AFTER POURING 20% ALLOWANCE FOR FORMWORK STRIPPING REMOVAL OF FORMWORKS 1-2 DAYS REMOVE FORMS OF FOOTING 2 DAYS REMOVE FORMWORK FOR SIDE OF BEAMS AND COLUMNS 3 DAYS REMOVE FORMWORKS FOR SLAB/ SOFFIT (PROPS LEFT UNDER) 7 DAYS REMOVE FORMWORKS FOR BEAM SOFFIT (PROPS LEFT UNDER) 14 DAYS REMOVE THE PROPS FOR 2ND FLOOR SLAB 14 DAYS REMOVE THE PROPS FOR BEAMS SPANNING 6 METERS 21 DAYS REMOVE THE PROPS FOR BEAMS SPANNING MORE THAN 6 METERS PROCEDURE FOR FORMWORK REMOVAL 1-SIDES OF BEAMS AND COLUMNS 2-SLAB SOFFIT 3-BEAM SOFFIT 4-REMOVAL OF PROPS FOR SLABS 5-REMOVAL OF PROPS FOR BEAMS OTHER TERMS & DEFINITIONS (FROM QUIZ, LECTURES, ETC.) 1.80 SQM/ 6-8 PCS PER BOX LAMINATED WOOD BAR NUMBER X 25.4 / 8 BAR DIA. (MM) VERNACULAR TERMS ADOBE ANCHOR LIYABE ALIGNMENT/ CHB LAYING ASINTADA ALIGNED KALINYA ALTERNATE UNI-SIN-OTRA ASTRAGAL BATIDURA BALUSTER BARANDILLAS BARREL BOLT TRANKILYA BASEBOARD RODAPIS BATHTUB BANIERA BEAM BIGA BOLT PIERNO BOTTOM CHORD BARAKILAN/ TIRANTE CANOPY MEDYA AGUA CEILING KISAME CEILING JOIST KOSTILYAHE CEMENT SEMENTO/ PAMASTA CEMENT BRICK LADRILYO CEMENT TILE BALDOSA CHANNEL PAAGUSAN CLAY LUAD CLOSED STRINGER MADRE DE ESCALERA COLLAR PLATE SINTURON CONCRETE SLAB LARGA MASA CONSTRUCTOR KONTRATISTA CORK PASAK CORNER KANTO CORNICE KORNISA CORRUGATED GI SHEET HIERO KANALADO CRUSHED STONE ESCONDRO DIAGONAL BRACE PIE DE GALLO DISH RACK BANGGUERAHAN DOOR FILLET BATIDORA DOOR JAMB HAMBA PINTUAN DOOR STOPPER VACIADA VERNACULAR TERMS DRESSED LUMBER SEPILLADO EARTH FILL ESCOMBRO EAVES ALERO/ SIBE EXTERIOR SIDING TABIKE FASCIA BOARD SINEPA FEET PIYE FENCES BAKOD FILL TAMBAK FLOOR JOIST SOLERAS FLOOR SILL GUILILAN FLOORBOARDS DOTAL FLOORING SAHIG/ SUELO FLUSH ALAHADO FOREMAN MAESTRO DE OBRA FRAMEWORK BALANGKAS GABLE ROOF DOS AGUAS GI STRAP LINGUETA GIRDER GUILILAN/ KULING GIRT SEPO GRAVEL GRABA GROOVE CANAL GUTTER/ CONDUCTOR ALULOD/ KANAL HALL CAIDA HANDRAIL GABAY HINGE BISAGRA HONEYCOMB AMPAW HORIZONTAL STUD PABALAGBAG INCHES PULGADA IRON HIERO IRON WASHER CHAPA KING POST PENDULON KITCHEN SINK PRIGADORA VERNACULAR TERMS LANDING MESA/ MESITA LAVATORY LABABO LEAD WASHER PITCHA LEAN TO ROOF SIBE LIMESTONE APOG MARBLE MARMOL MASON KANTERO MASONRY FILL LASTILYAS MITER KANTO MESA MORTAR JOINTS KOSTURA MOULDING MULDURA NAIL SETTER PUNSOL NAILS PAKO OAKUM ESTOPA OPEN STRINGER HARDINERA PANEL DOOR DE BANDEHA PATTERN/ SCHEDULE PLANTILYA PICKWORK PIKETA PLASTERED COURSE KUSTURADA PLUG TAPON PLUMB BOB HULOG POST HALIGE/ POSTE PROJECTION BOLADO PURLINS REOSTRA PUTTY MASILYA QUEEN POST PRASES RABBET VACIADA REINFORCING BARS KABILYA RIDGE ROLL KABALLETE RISER TAKIP SILIPAN RIVETS RIMATSE SAND BUHANGIN VERNACULAR TERMS SCAFFOLDING ANDAYO/ BARAL DE KADENA/ PLANTSA SCRATCH COAT REBOKADA/ REBUEDA SCREW NUT TUERKA SCREW THREAD ROSKAS SEPTIC VAULT POSO NEGRO SHOWER DUTCHA SINK PRIGADERO SKETCH PLAN KROKIS SOLDER HINANG SOLDERING LEAD/ NICOLITE BAR ESTANYO SPACING OF GAP BIENTO SPLIT KNOB POLEYA STAKE ESTAKA STUCCO/ PLASTER PALITADA TEMPER SUBAN, SUBUHAL TINSMITH LATERO TOP CHORD TAHILAN TRELLIS KAPATAS/ PERGOLA TRUSS KILO VARNISH FINISH MONYEKA VERTICAL STUD PILARETE WAINSCOTING TILES ASOLEHOS WALL POST BAGAD WASHER PITSA WATER CLOSET INODORO WINDOW HEAD SUMBRERO WINDOW SILL PASAMANO WIRE KAWAD/ ALAMBRE WIRING KNOB POLEYA WOOD GRAIN HASPE WOOD PLANK TABLA [Show More]

Last updated: 8 months ago

Preview 5 out of 200 pages

Loading document previews ...

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$11.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Dec 01, 2024

Number of pages

200

Written in

Additional information

This document has been written for:

Uploaded

Dec 01, 2024

Downloads

0

Views

31