CES EduPack – Design Problem 2

Using Level 2, with ‘Metric Units’ and ‘Use Display Units for Temperature’:

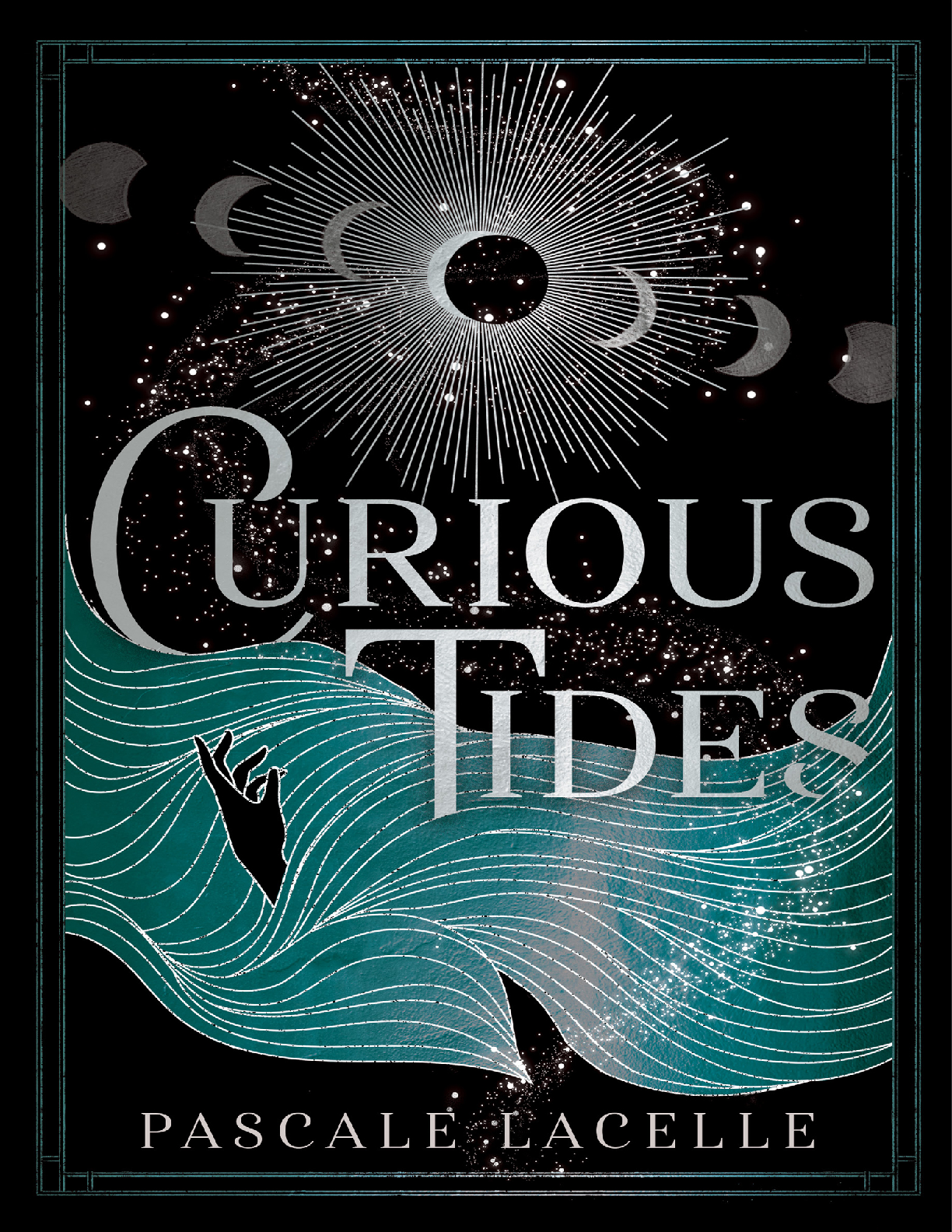

1. Use the ‘Advanced’ feature to construct a graph of ? = ?ூ⁄√?? for an internal crack of length

2a = 1 mm v

...

CES EduPack – Design Problem 2

Using Level 2, with ‘Metric Units’ and ‘Use Display Units for Temperature’:

1. Use the ‘Advanced’ feature to construct a graph of ? = ?ூ⁄√?? for an internal crack of length

2a = 1 mm versus density (?). Label the five materials with highest values of ?⁄? on the graph.

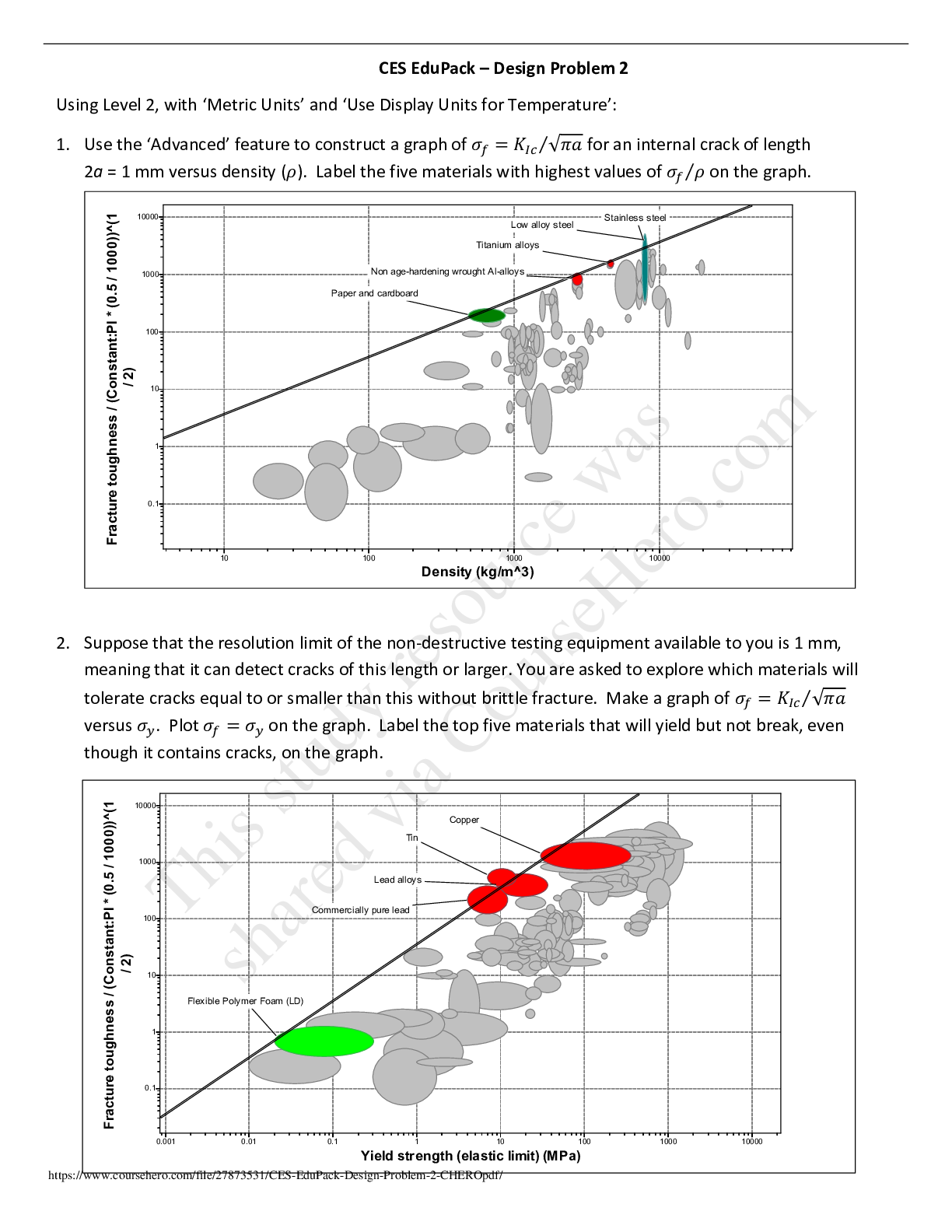

2. Suppose that the resolution limit of the non-destructive testing equipment available to you is 1 mm,

meaning that it can detect cracks of this length or larger. You are asked to explore which materials will

tolerate cracks equal to or smaller than this without brittle fracture. Make a graph of ? = ?ூ⁄√??

versus ?

௬. Plot ? = ?௬ on the graph. Label the top five materials that will yield but not break, even

though it contains cracks, on the graph.

Density (kg/m^3)

10 100 1000 10000

Fracture toughness / (Constant:PI * (0.5 / 1000))^(1

/ 2)

0.1

1

10

100

1000

10000

Paper and cardboard

Non age-hardening wrought Al-alloys

Titanium alloys

Low alloy steel

Stainless steel

Yield strength (elastic limit) (MPa)

0.001 0.01 0.1 1 10 100 1000 10000

Fracture toughness / (Constant:PI * (0.5 / 1000))^(1

Flexible Polymer Foam (LD)

Copper

Commercially pure lead

Tin

Lead alloys

This study resource was

shared via CourseHero.com3. Create a Yield Strength v. Density graph. Apply the following Limits: Yield Strength greater than 300 MPa,

minimum elongation of 5%, and Density less than 3,000 kg/m3. Then use the ‘Properties’ button to modify

the axes so that the x-axis has a range of 1,000 – 10,000 kg/m3 and the y-axis has a range of 10 – 1,000

MPa. Finally, label the remaining materials on the graph.

4. Valve springs for high performance automobile engines must be light to minimize inertial loads, since part

of their mass moves with the valves. At high engine speeds the valves, if heavy, bounce out of contact with

the valve itself (‘valve bounce’), impeding the flow of gas into and out of the combustion chamber. The

energy stored per unit volume is equivalent to modulus of resilience of a material, i.e., ? = ?௬ଶ⁄(2?). The

energy stored per unit weight is then, ? = ?௬ଶ⁄(2??). So the best choices are materials with the highest

value of ? = ?

ଶ௬

⁄(2??). Make a bar graph with this quantity on the y-axis, and label the top five ‘best’

materials on the graph. NOTE: In order for the material to be stiff enough, it must have E > 20 GPa. In

addition, engine operation temperatures can reach 200°C. Therefore, use a Limit of E > GPa, and a Limit of

Maximum Service Temperature minimum of 200°C.

Density (kg/m^3)

1000 2000 5000 10000

Yield strength (elastic limit) (MPa)

10

100

1000

Cast Al-alloys

Wrought magnesium alloys

Age-hardening wrought Al-alloys

Aluminum/Silicon carbide composite

(Yield strength (elastic limit)^2) / (2 * Density * Young's

modulus)

CFRP, epoxy matrix (isotropic)

Titanium alloys

Wrought magnesium alloys

Age-hardening wrought Al-alloys

Nickel-based superalloys

[Show More]