HW 3 Solution

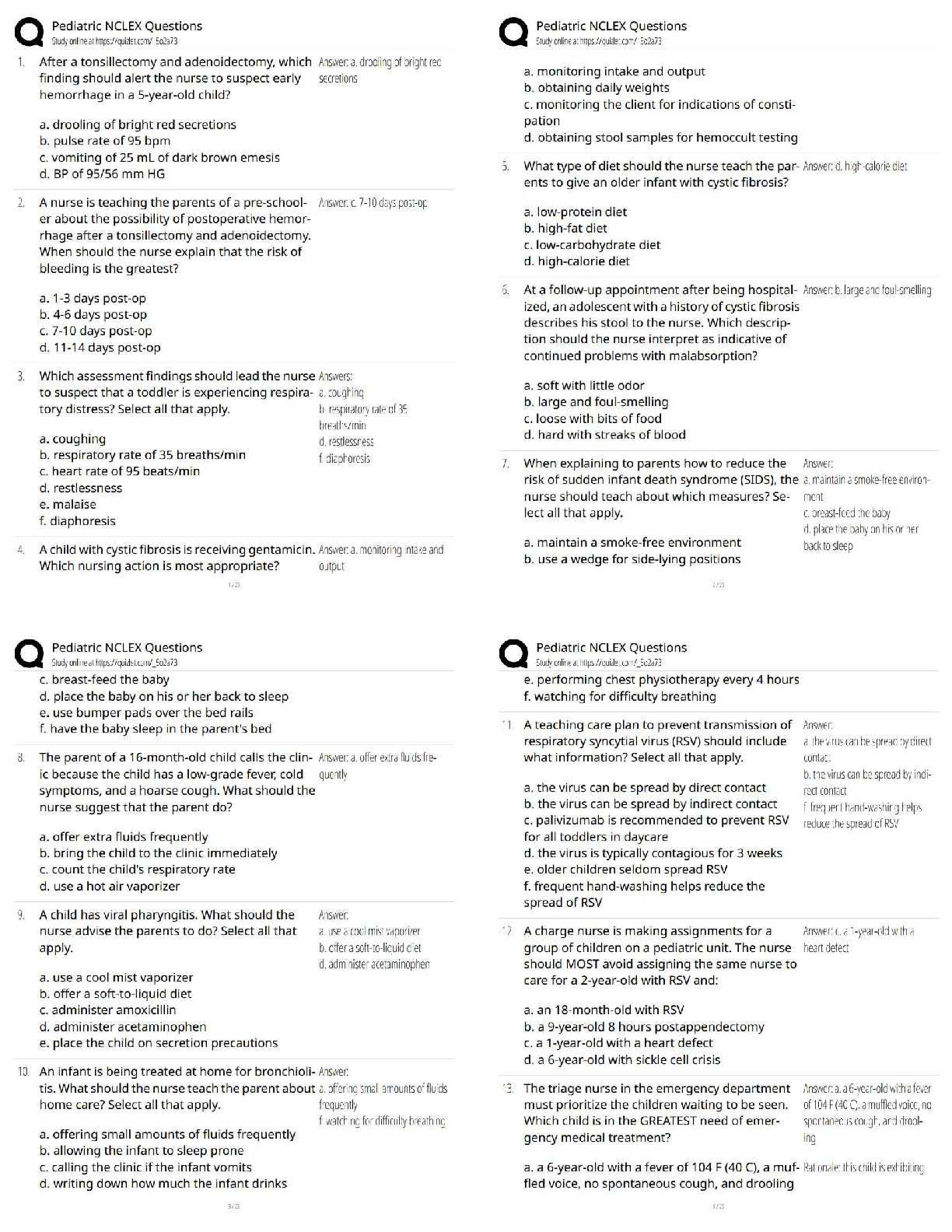

1) A manual assembly line has 25 workstations and the manning level is 1.0. The work content

time to assemble the product is 29.5 min. Production rate of the line is 40 units/hr. The

proportion uptime is

...

HW 3 Solution

1) A manual assembly line has 25 workstations and the manning level is 1.0. The work content

time to assemble the product is 29.5 min. Production rate of the line is 40 units/hr. The

proportion uptime is 96% and the repositioning time is 9 sec. Determine the balance delay on

the line. 2) A manual assembly line is being designed for a product whose annual demand is 100,000 units.

The line will operate 50 wk/yr, 5 shifts/wk, and 8 hr/shift. Work units will be attached to a

continuously moving conveyor. Work content time is 42.0 min. Assume line efficiency is 0.95,

balancing efficiency is 0.93 or slightly less, repositioning time is 6 sec, and manning level is

1.4. Determine (a) average hourly production rate to meet demand and (b) number of workers

required. (c) If each station on the line is 3 m long, what is the total length of the assembly

line? 3) An automobile final assembly plant is being planned for an annual production of 150,000

cars. The plant will operate one shift, 250 days per year, but the duration of the shift (hr/shift)

is to be determined. The plant will be divided into three departments: (1) body shop, (2) paint

shop, and (c) general assembly. The body shop welds the car bodies, and the paint shop coats

the welded car bodies. Both of these departments are highly automated. The general

assembly department has no automation, but a moving conveyor is used to transport the cars

through the manual workstations. A total of 14.0 hours of direct labor (work content time)

are accomplished in general assembly. Based on previous lines installed by the company, it is

anticipated that the following design parameters will apply to the general assembly

department: line efficiency = 95%, balance efficiency = 94%, repositioning time = 0.10 min,

and manning level = 2.5. If the plant must produce 60 cars per hour, determine the following

for the general assembly department: (a) number of hours the shift must operate, (b) number

of workers required, and (c) number of workstations. 4) A manual assembly line is being planned to produce a small consumer appliance. The work

elements, element times, and precedence constraints are indicated in the table below. The

workers will work for 420 min/shift and must produce 350 units/day. A mechanized

conveyor, moving at a speed of 1.4 m/min will transport work units through stations.

Manning level is 1.0, and repositioning time is 0.1 min. Because worker service time at each

station is variable, it has been decided to use a tolerance time that is 1.5 times the cycle time.

(a) Determine the ideal minimum number of workers. (b) Use the largest candidate rule to

solve the line balancing problem. (c) For your line balancing solution, compute the balancing

efficiency. Determine (d) spacing between work units on the line and (e) required length of

each workstation to satisfy the specifications of the line. 5) Solve the previous problem but use the Kilbridge and Wester method in part (b). 6) Solve the previous problem but use the ranked positional weights method in part (b).

[Show More]