Economics > CASE STUDY > Heriot-WattECONOMICS K17EIOB_Questions (All)

Heriot-WattECONOMICS K17EIOB_Questions

Document Content and Description Below

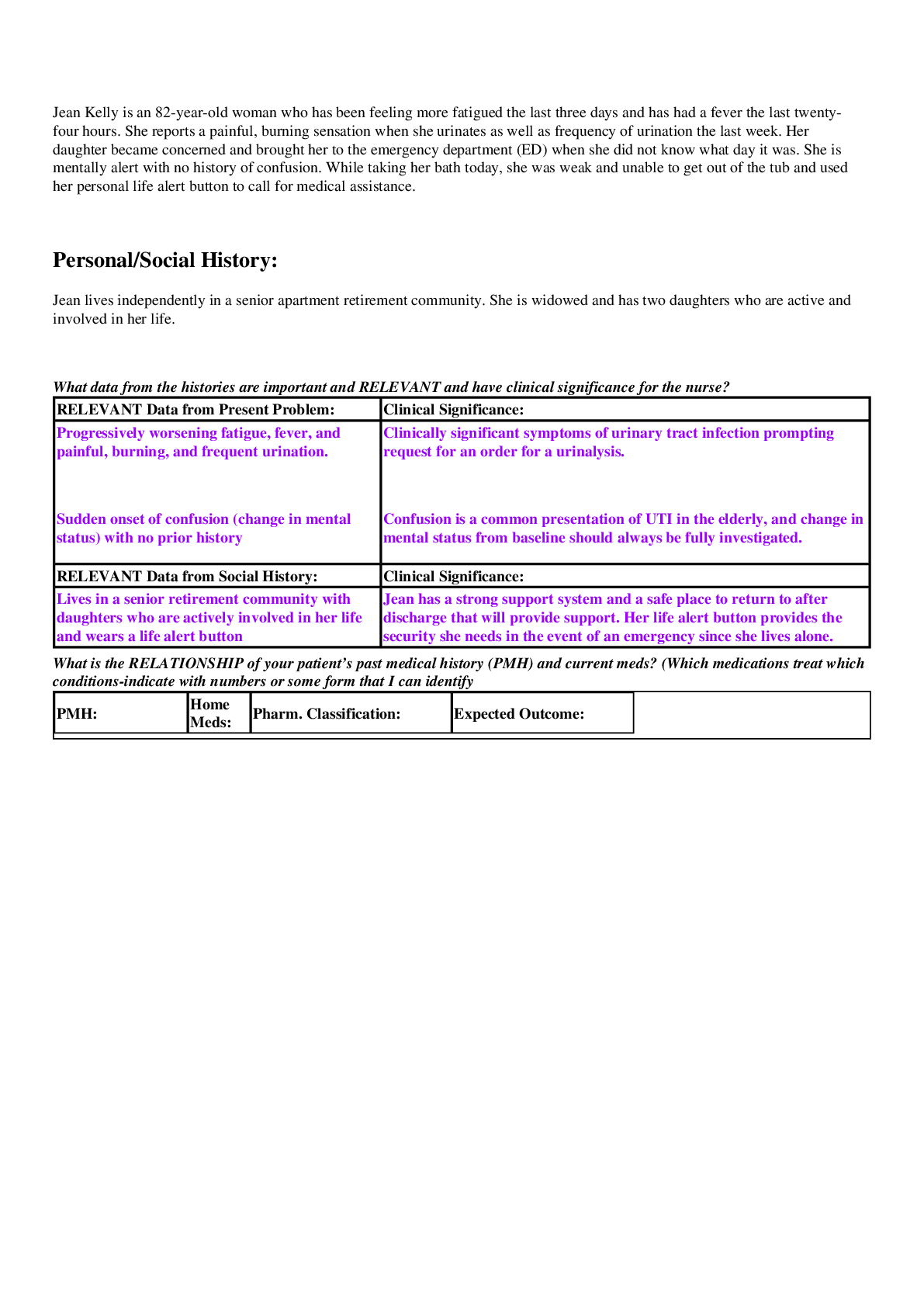

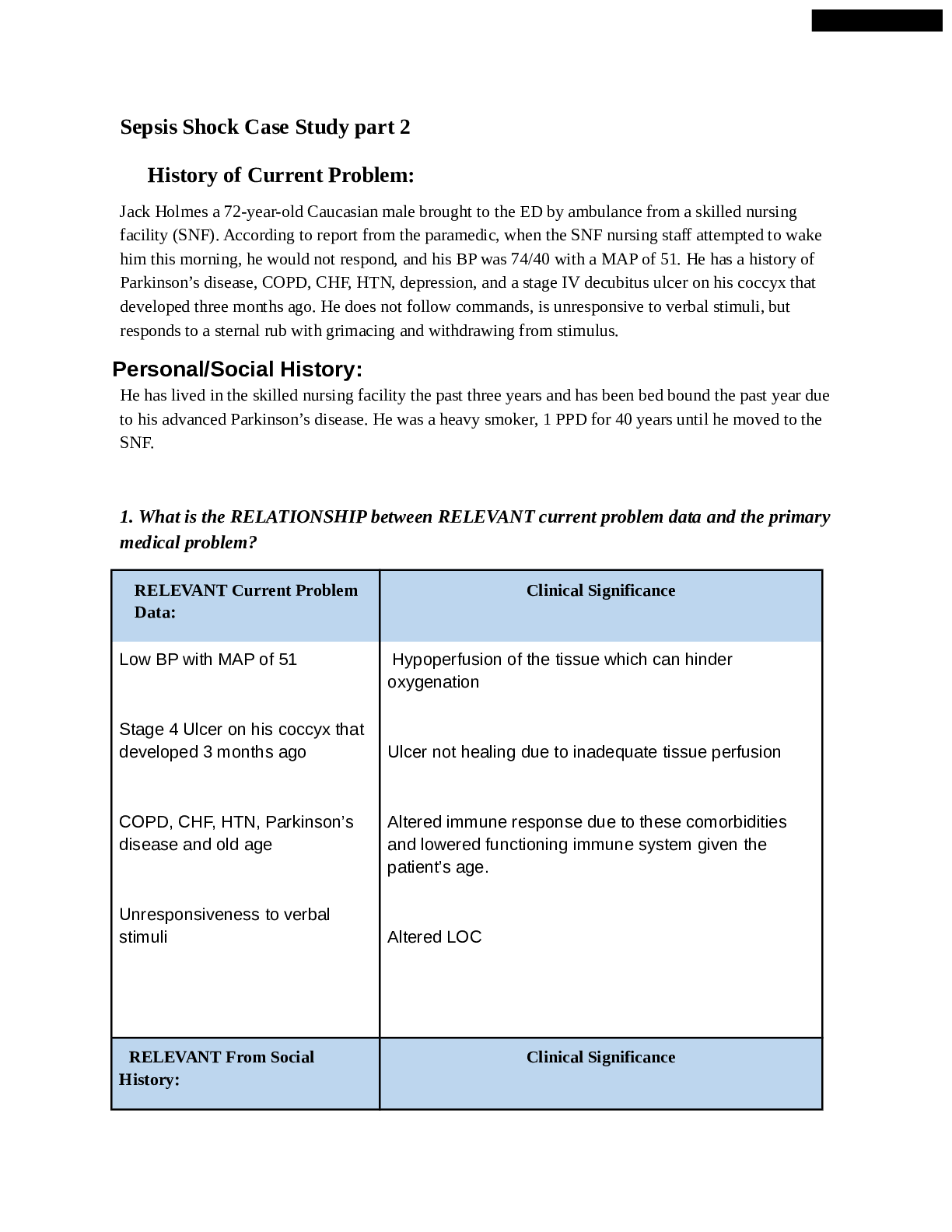

OB: Case Study In the world of motoring, the BMW brand has long been synonymous with high-quality products, advanced engineering and high performance. Away from the cars themselves, the company has ... been striving to apply those qualities to its manufacturing plant at Cowley in Oxford. When BMW took over the Rover group in 1994, it acquired in the MINI the most British of products, but it also inherited a British car-manufacturing culture born out of decades of industrial relations strife and low productivity. Six years later BMW broke up the Rover group and sold it off in pieces – with the Rover brand being taken over by the independently run MG Rover Group and production of the Land Rover moving to Ford. The German manufacturer retained the MINI brand and set about overhauling a product that had sold more than five and a half million cars in more than 40 years of production. It also recognised the urgent need to change working practices at the plant. Monika Lampe, change manager at BMW Group Plant Oxford, says that a revamp of working practices was essential for the new model to succeed. ‘When we started at Cowley, the legacy of Rover and the work culture was very much “us and them”. There was a blame culture within the plant and, to be honest, people used to leave their brains at the gate,’ she says. ‘We were in a competitive market, and to compete as a business we had to create a culture of success. We had to change processes, attitudes and behaviour and to empower staff and involve them in the processes.’ So, in 2000, the firm invested more than £230 million in refitting the Oxford plant and launching a major change programme called ‘The New Oxford Way’ (NOW). This focused on three key challenges: upgrading the site and processes to world-class standards; integrating the different BMW and Rover cultures, expectations and experiences; and launching a new vehicle. The programme was made up of nine ‘sub-projects’ aimed at embedding a variety of attributes into the culture: working in groups; management performance; Oxford identity; information/communication; integration of support functions; competence assessment training; standardised processes; target management process; and reward management. The central element in the implementation of these projects is known as ‘WINGS’ – a contraction of ‘Working in Groups’ – which involved the creation of hundreds of ‘self-steered’ teams of between 8 and 15 people across the plant’s manufacturing areas. WINGS teams have been given the power to tackle production problems themselves, when previously they would have had to call on other departments. The group members also now rotate tasks within their area to break up the monotony of production-line work. In addition, rather than being management-led, the focus is now on initiative and self-management, and employees have received external training and coaching in working as part of a team. Heike Schneeweis, HR Director at BMW, says the setting-up of WINGS created a turnaround in both working practices and employee behaviours. ‘The development of self-steered teams diminished the power of the traditional hierarchical structure and gave much more responsibility to the working teams in the manufacturing area,’ she says. ‘It placed continuous improvement and the achievement of plant improvement targets directly into the hands of the team members.’ The day-to-day duties of one person from each WINGS team have been halved [Show More]

Last updated: 3 years ago

Preview 1 out of 10 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$11.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Jun 10, 2021

Number of pages

10

Written in

All

Additional information

This document has been written for:

Uploaded

Jun 10, 2021

Downloads

0

Views

60