DML Test 2 Advanced Lathe Operations

you have a rectangular workpiece that needs a facing operation plus center drilling, and a

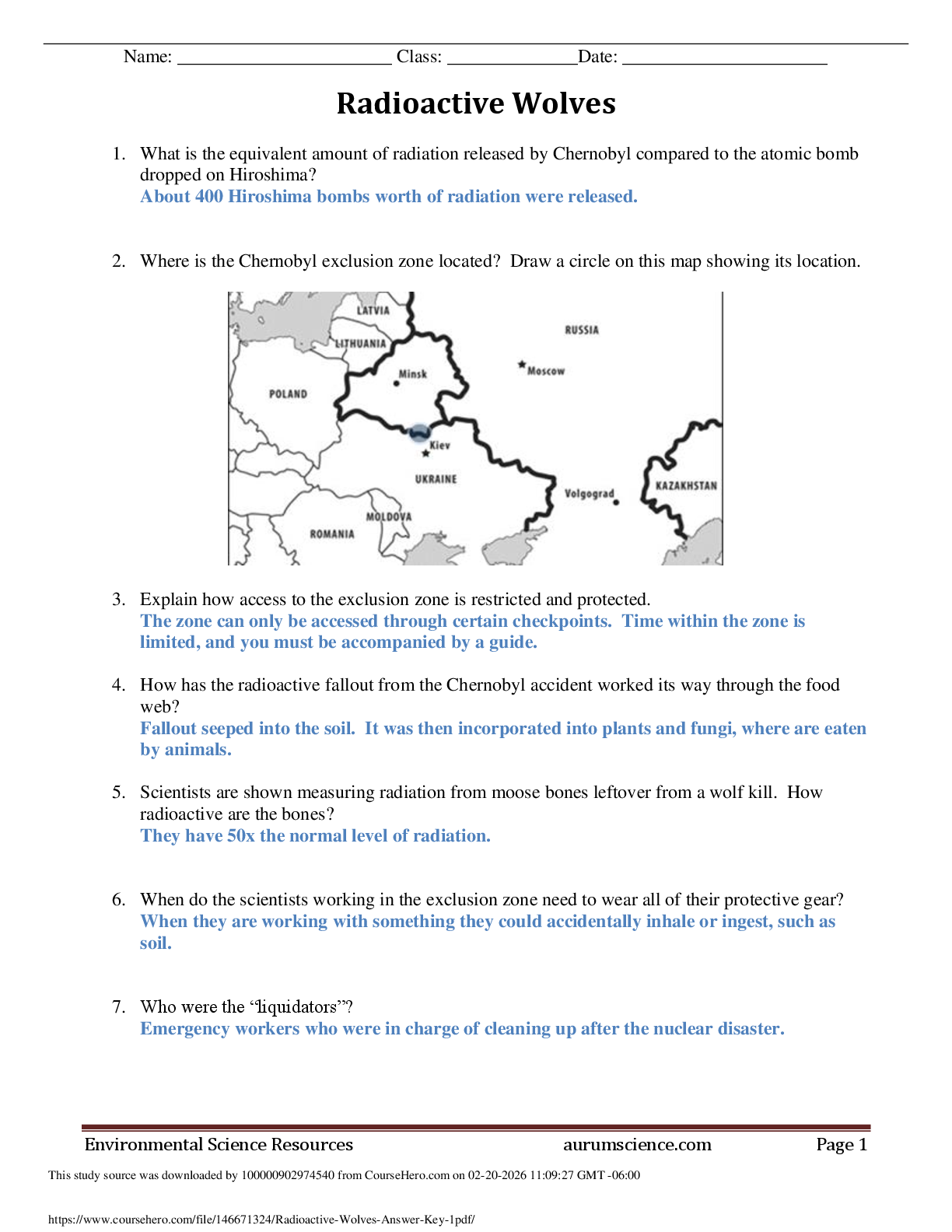

universal chuck is mounted on the lathe spindle. What is your procedure to prepare for

ma

...

DML Test 2 Advanced Lathe Operations

you have a rectangular workpiece that needs a facing operation plus center drilling, and a

universal chuck is mounted on the lathe spindle. What is your procedure to prepare for

machining? - ✔✔a lathe board is placed on the ways under the chuck, and the chuck removed,

because it is the wrong chuck to hold rectangular work. The mating parts of an independent

chuck and the lathe spindle are cleaned and the chuck is mounted. The part is rouchly centered in

the jaws and adjusted to center by using the back of a tool holder or a dial indicator

Should the point of the tool be set above, below, or at the center of the spindle axis when taking a

facing cut? - ✔✔center

If you set the quick-change gearbox to .012 in, is that considered a roughing feed for facing? -

✔✔no, the resultant facing feed would be approximately .003 to .005 in which would be a

finishing feed

An alignment step must be machined on a cover plate .125 in, +- .003 in, in depth. What

procedure should be taken to face to this depth? how can you check your final finish cut? -

✔✔the compound must be swung to either 30 or 90 degrees so that the tool can be fed into the

face of the work by a measured amount. A depth micrometer or a micrometer caliper can be used

to check the trial finish cut

What tool is used for facing shaft ends when they are mounted between centers? In what way is

this tool different from a turning tool? - ✔✔A right-hand facing tool is used for shaft ends. It is

different from a turning tool in that its point is only a 58-degree included angle to fit in the

narrow space between the shaft face and the center

If the cutting speed of aluminum is 300 sfpm and the workpiece diameter is 4 in, what is the

rpm? the formula is rpm = (4(CS))/D - ✔✔(4(300))/4 = 300rpm

Give two reasons for center drilling a workpiece in a lathe - ✔✔prepare work for turning

between centers, spotting workpieces for drilling in the lathe

name two causes of center-drill breakage - ✔✔feeding the drill too fast and having the lathe

speed too slow, off center tailstock, off center workpiece in a steady rest, lack of cutting oil

What happens when you drill too deeply with a center drill? - ✔✔the sharp edge provides a poor

bearing surface and soon wears out of round, causing machining problems such as chatter

What is the drill point diameter of a number 5 center drill? - ✔✔3/16 in

Give two advantages and disadvantages of turning between centers - ✔✔no loss of concentricity,

removed from the chuck and returned without loss of synchronization between the thread and

tool; cutting off between centers is not done because it would break the parting tool and ruin the

work, steady rest work is not done with work mounted in a center in the headstock spindle

What other method besides turning between centers is extensively used for turning shafts and

long workpieces supported by the tailstock center? - ✔✔workpiece is held in a chuck on one end

and in the tailstock center on the other end

What factors tend to promote or increase chip curl so that safer chips are formed? - ✔✔coarser

feeds, deeper cuts, smaller rake angles, chip breakers

Name three kinds of centers used in the tailstock and explain their uses - ✔✔dead centers are

hardened 60-degree centers that do not rotate with the work but require high-pressure lubricant,

ball bearing centers turn with the work and do not require lubricant, pipe centers turn with the

work and are used to support tubular material

how is the dead center correctly adjusted? - ✔✔no end play in the workpiece and the bent tail of

the lathe dog free to move in the slot

Why should the dead center be frequently adjusted when turning between centers - ✔✔because

of expansion of he workpiece from the heat of machining, it tightens on the center, thus causing

more friction and more heat; this could ruin the center

Why should you avoid excess overhang with the tool and toolholder when roughing? -

✔✔excess overhang promotes lack of rigidity, causing chatter and tool breakage

Calculate the rpm for roughing a 1.5 in diameter shaft of machine steel - ✔✔(4(90))/1.5 =

240rpm

What would the spacing or distance between tool marks on the workpiece be with a .010 in feed?

- ✔✔The spacing would be .010 in, as the tool moves that amount for each revolution of the

spindle

What should the feed rate be for roughing? - ✔✔1/5 to 1/10 as much as the depth of cut, this

should be limited to what the tool, workpiece, or machine can stand without undue stress

how much should be left for finishing? - ✔✔for most purposes where liberal tolerances are

allowed, .015 to .030 in can be left for finishing, When closer tolerances are required, two finish

cuts are taken, with .005 to .010 in left for the last finish cut

Describe the procedure in turning to size predictably? - ✔✔after roughing is completed, .015 to

.030 in is left for finishing; diameter is checked with a micrometer and the remaining amount is

dialed on the crossfeed micrometer collar; a short trial cut is taken and the lathe is stopped; this

diameter is again checked; if it is within tolerance a finish cut is taken

What happens to the workpiece when the centers are out of line? - ✔✔it becomes tapered

What happens to the workpiece when the tailstock is offset toward the operator? - ✔✔it is

tapered with the small end at the tailstock

Name three methods of aligning the centers - ✔✔witness mark on the tailstock, using a test bar,

taking a light cut on a workpiece and measuring

which measuring instrument is used when using a test bar? - ✔✔dial indicator

By what means is the measuring done when checking taper by taking a cut? - ✔✔micrometer,

the tailstock is set over with a dial indicator

Why are drilled holes not used for bores in machine parts such as pulleys, gears, and bearing

fits? - ✔✔would be loose on the shaft and would not run true

Describe the procedure used to produce drilled holes on workpieces in the lathe with minimum

oversize and runout - ✔✔workpiece is center spotted with a center drill at the correct rpm, and if

the hole is to be more than 3/8 in in diameter, a pilot drill is put through at a slower speed

What is the chief advantage of boring over reaming in the lathe? - ✔✔bore runs true with the

centerline of the lathe and the outside of the workpiece, if the workpiece has been setup to run

true, this is not always possible when reaming bores that have been drilled, because the reamer

follows the eccentricity or runout of the bore

List five ways to eliminate chatter in a boring bar - ✔✔shorten the bar overhang if possible;

reduce spindle speed; make sure the tool is on center; use as large a diameter bar as possible

without binding in the bore; use tuned or solid carbide boring bars

Explain the differences between through boring, counterboring, and boring blind holes -

✔✔through- boring a constant diameter all the way through the part, counter- making two or

more diameters in the same bore, usually with 90-degree or square internal shoulders, blindbores that do not go all the way through

By what means are grooves and thread relief made in a bore? - ✔✔bores of specially shaped or

ground tools in a boring bar

reamers will follow an eccentric drilled hole, thus producing a bellmouth bore with runout. What

device can be used to help eliminate bellmouth? does it help remove the runout? - ✔✔a floating

reamer holder, does not remove runout

Machine reamers produce a better finish than is obtained by boring. how can you get an even

better finish with a reamer? - ✔✔hand ream

Cutting speeds for reaming are (twice, half) that used for drilling; feeds used for reaming are

(twice, half) that used for drilling - ✔✔half, twice

Which would be best for making a 6 in diameter internal thread using an engine lathe: a tap or a

single-point threading tool? explain - ✔✔single point threading tool, large taps need too much

force

how can you avoid drilling oversize with a tap drill? - ✔✔drill undersize and ream to a larger

size

Standard plug or bottoming taps can be used when hand tapping in the lathe. If power is used,

what kid of tap works best? - ✔✔spiral-point tap

Why would threads cut with a hand die in a lathe not be acceptable for using on a feed screw

with a micrometer collar? - ✔✔variations in pitch of the hand-cut threads would cause the

micrometer collar to give erroneous readings

By what means is thread relief on external grooves produced? - ✔✔specially ground tools

similar to internal grooving tools except that they have less end relief

If cutting fluid is not used on parting tools, or chips do not clear out of the groove because of a

heavy feed, what is generally the immediate result? - ✔✔parting tools tend to seize in the work,

with the possibility of a broken parting tool and misaligned or damaged work

how can you avoid chatter when cutting off stock with a parting tool? - ✔✔maintain a rigid setup

and keep enough feed to produce a continuous chip if possible

State three reasons for knurling - ✔✔improve appearance of a part, provide a good gripping

surface, increase diameter of a part for press fits

Ordinary knurls do not cut. In what way do the make diamond or straight pattern on the

workpiece? - ✔✔displacing the metal with high pressures

If a knurl is producing a double impression, what can you do to make it develop a diamond

pattern? - ✔✔adjust up or down or angle the toolholder 5 degrees

How can you avoid producing a knurled surface on which the metal is flaking off? - ✔✔stop the

knurling process when the diamond points are almost sharp, use a lubricant while knurling

Give one disadvantage of the sharp V thread - ✔✔The sharp V thread can be easily damaged

during handling if it is dropped or allowed to strike against a hard surface

Explain the difference between the threads per inch and the pitch of the thread - ✔✔The pitch is

the distance between a point on a screw thread to a corresponding point on the next thread

measured parallel to the axis. "Threads per inch" is the number of threads in one inch.

Name two similarities and two differences between American National and Unified threads -

✔✔American National Standard and Unified Standard threads both have the 60-degree included

angle and are both based on the inch measure with similar pitch series. The depth of the thread

and the classes of thread fits are different in the two systems

What is a major reason for thread allowances and classes of fits? - ✔✔To allow for tolerancing

of external and internal threads to promote standardization and interchangeability of parts

What does 1/2 - 20 UNC-2A describe? - ✔✔This describes a diameter of 1/2 in, 20 threads per

inch, and Unified coarse series external thread with a class 2 thread tolerance

The root truncation for unified threads and for American National threads is found by .125P.

What should the flat on the end of the threading tools be for both systems on a 1/2 - 20 thread? -

✔✔The flat on the end of the tool for 20 threads per inch should be P = .050 x .125 = .006 in for

American National threads and for Unified threads

How far should the compound set at 30 degrees move to cut a 1/2 - 20 Unified thread? (The

formula is .701/n) How far should the compound move to cut a 1/2 - 20 Unified form thread?

(The formula is .701/n) - ✔✔The compound at 30 degrees will move in .708/20 = .0354 in for

Unified threads. The compound will move in .75/20 = .0375in for American National threads

Explain the difference between the fit of threads and the percent of thread - ✔✔The fit of the

thread refers to classes of fits and tolerances, while percent of thread refers to the actual minor

diameter of an internal thread, a 100-percent thread being full-depth internal threads

Name two metric thread standard systems - ✔✔The Systeme International (SI) thread and the

British Standard ISO Metric Screw Threads are two metric thread systems in use

How are Unified and metric thread forms similar? - ✔✔Both are 60-degree forms

[Show More]

.png)

Updated 2022.png)

.png)