Mechanical Engineering > PROJECT FINAL > Texas A&M University - MEEN 489489Proj3final. (All)

Texas A&M University - MEEN 489489Proj3final.

Document Content and Description Below

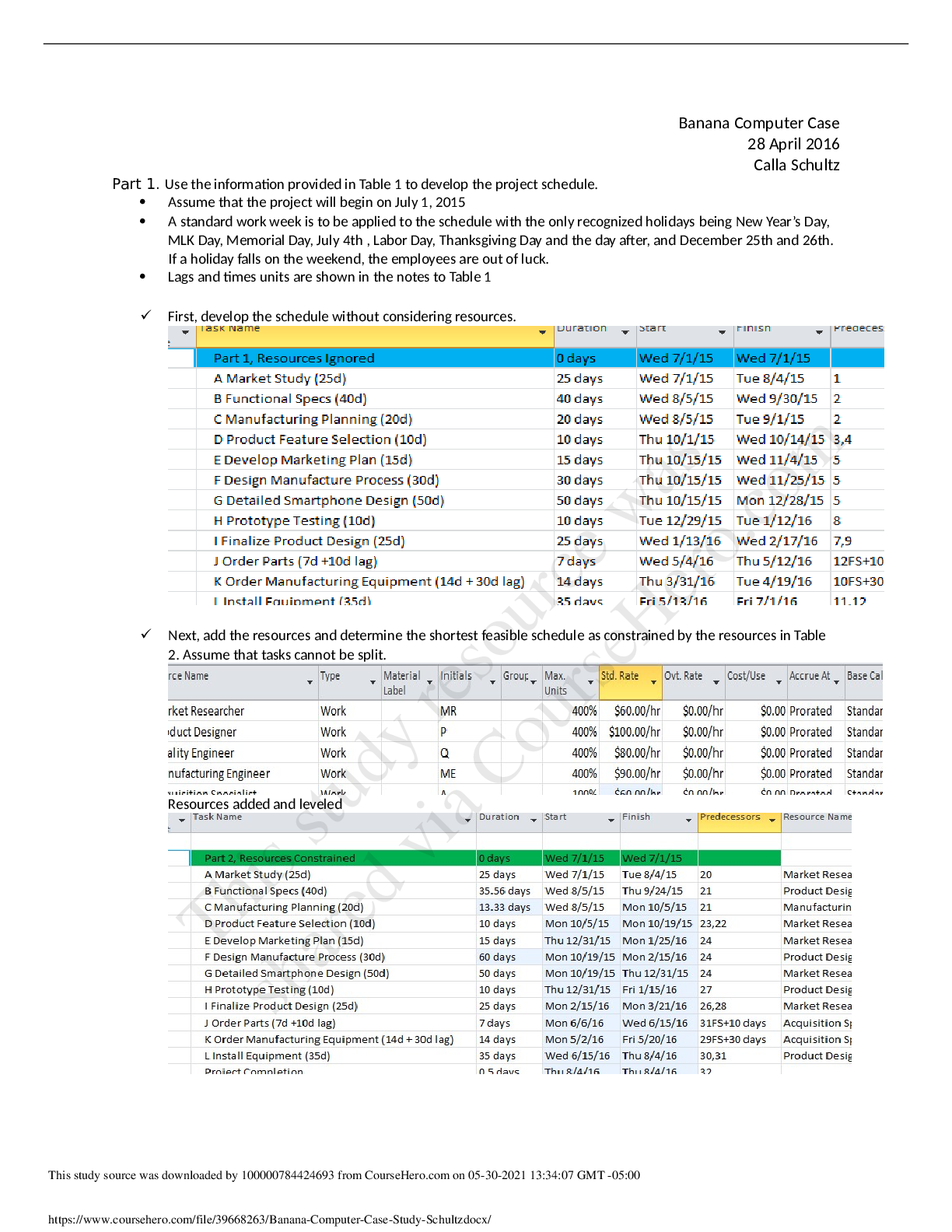

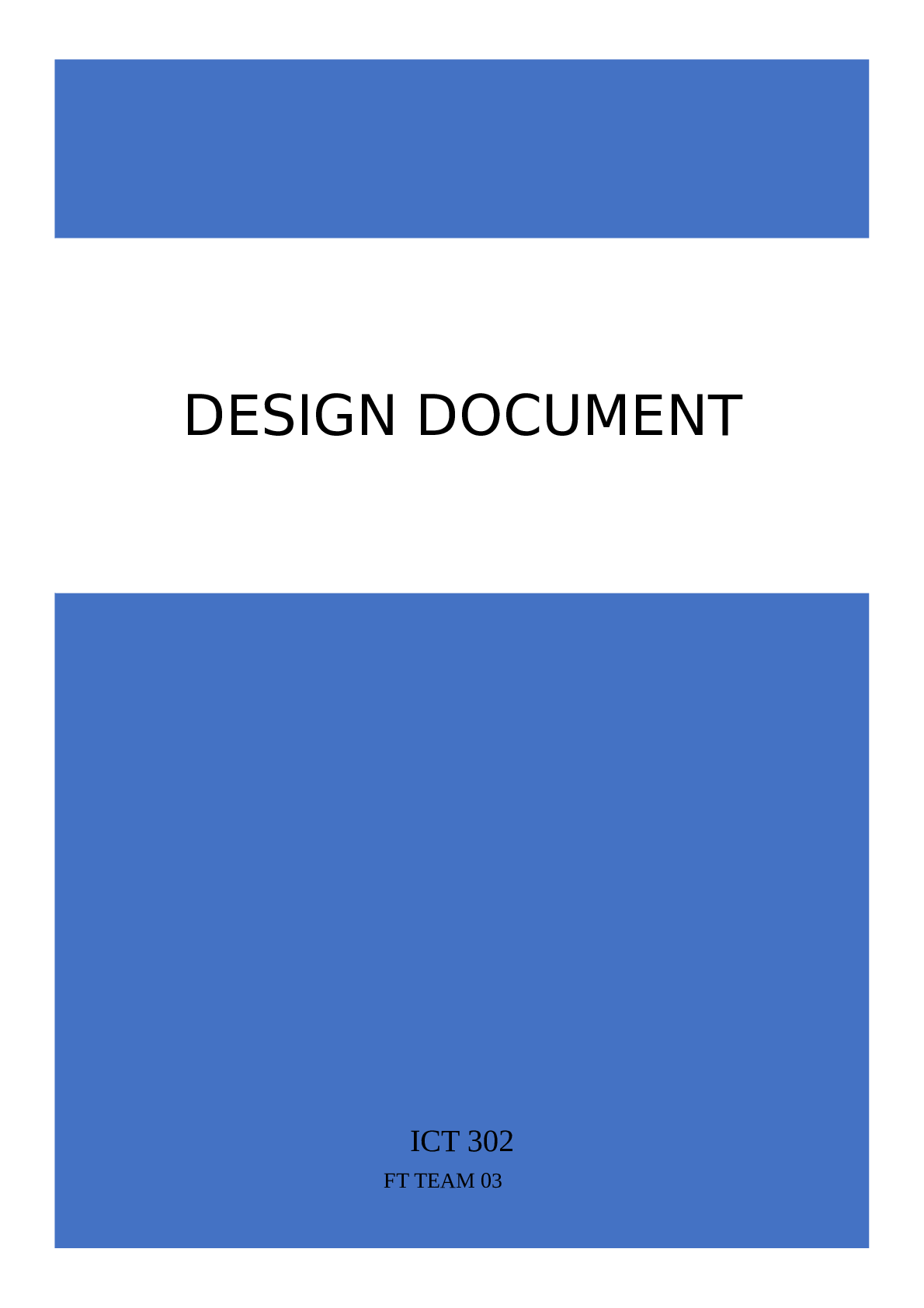

MEEN 489, Mechanics of Materials Spring 2020 Project 3 Assignment DUE SUNDAY, 5 APR by 11:59 pm Name: A-10 WING BENDING STRESS AND DEFLECTION ANALYSIS The A-10 aircraft is designed to support num ... erous combat missions including close air support, forward air control, anti-armor, strike control and reconnaissance, air interdiction, and combat search and rescue. Therefore, its wing is designed to carry a multitude of weapon load configurations, as shown in Figure 1. As a structural engineer, your assignment is to analyze the shear and bending loads of the center and outer wing sections for one configuration along with the bending stresses and deflection of the center wing. x Anti-Armor Configuration with three Mk-90 Rockeye II cluster bombs each located at weapons pods 4, 5, 7, and 8. FIGURE 1. Weapons Capabilities and Configurations of A-10 Aircraft STRUCTURAL DESCRIPTION: As shown in Figure 2, the wing group consists of three main sections: the center section and two outer panels. The structure consists of three spars and stiffened covers. The covers are separate integral planks between spars in the center section, and a one-piece skin panel with separate stiffeners in the outer panels. The three-spar construction allows for redundant load paths for shear, torsion, and for a better moment distribution. McKenzie ONeal 'MEEN 489, Mechanics of Materials Spring 2020 Project 3 Assignment DUE SUNDAY, 5 APR by 11:59 pm FIGURE 2. A-10 Wing Group Components The wing center section is a basic wing box structure consisting of three spars, integrally stiffened covers, and ribs that are spaced throughout the section. The spars stabilize the skin panels, minimize skin deflection, and carry loads imposed by external stores, fuel, and flight maneuvers. The skins are relatively thick, tapered, machined and shot peened to contour. The skin covers are made with integral stiffeners to minimize fuel leakage and are in separate panels from front to mid spar and mid spar to rear spar. The top skin covers and upper spar caps are made from 7075-T76511 aluminum alloy extrusions, and the bottom skin covers and lower spar caps are made from 2024-T3511 aluminum alloy extrusions. The front, mid, and rear spar webs are made from 7075-T6, 7075-T76 and 7075-T76 clad aluminum alloy sheet, respectively. The outboard wing structure is a two-cell box beam. The outer panels consist of three spars and stringers attached to covers, which extend in one piece from the front to rear spars, and ribs that are spaced throughout the panels. The top cover assembly consists of a chem-milled 7075-T6 clad aluminum alloy sheet with 7075-T76511 extruded stringers attached to it, while the lower cover assembly consists of a chem-milled 2024-T3 clad aluminum alloy sheet with 2024-T3511 extru [Show More]

Last updated: 3 years ago

Preview 1 out of 14 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$7.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Mar 27, 2021

Number of pages

14

Written in

All

Additional information

This document has been written for:

Uploaded

Mar 27, 2021

Downloads

0

Views

128