Engineering > PROJECT FINAL > UTILIZATION OF HOT REINJECTION BRINE FOR MORE ENERGY PRODUCTION USING AN ORC SYSTEM ( FINAL YEAR PRO (All)

UTILIZATION OF HOT REINJECTION BRINE FOR MORE ENERGY PRODUCTION USING AN ORC SYSTEM ( FINAL YEAR PROJECT )

Document Content and Description Below

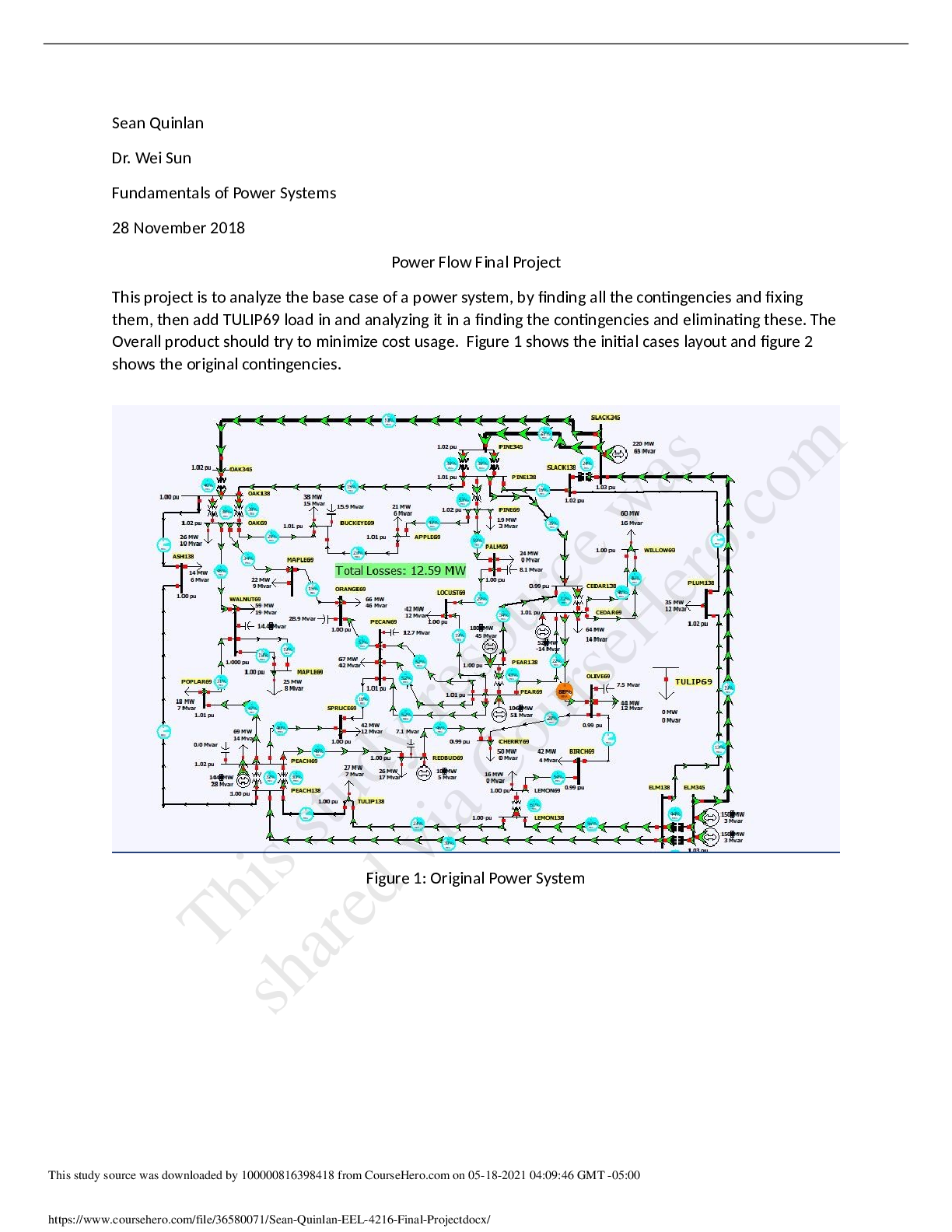

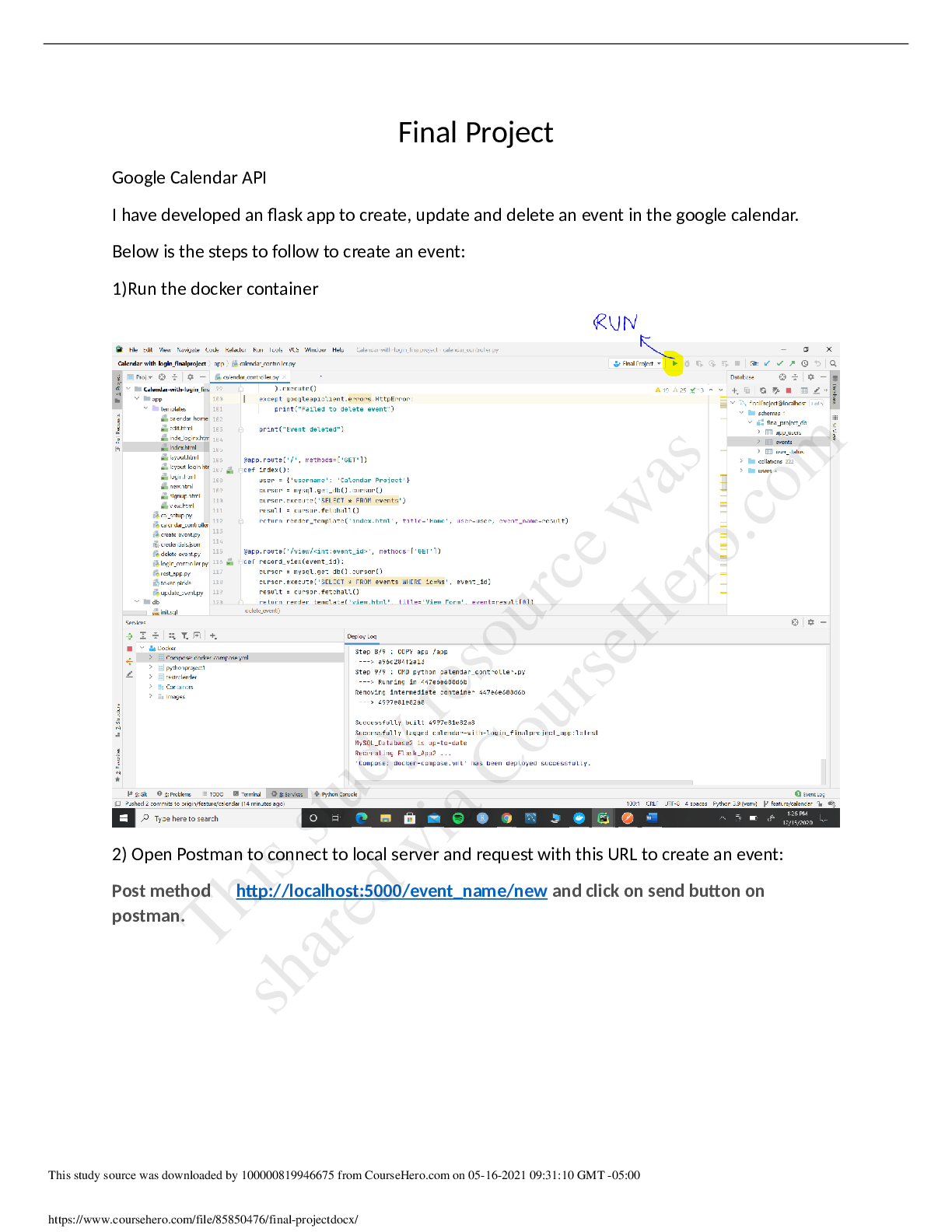

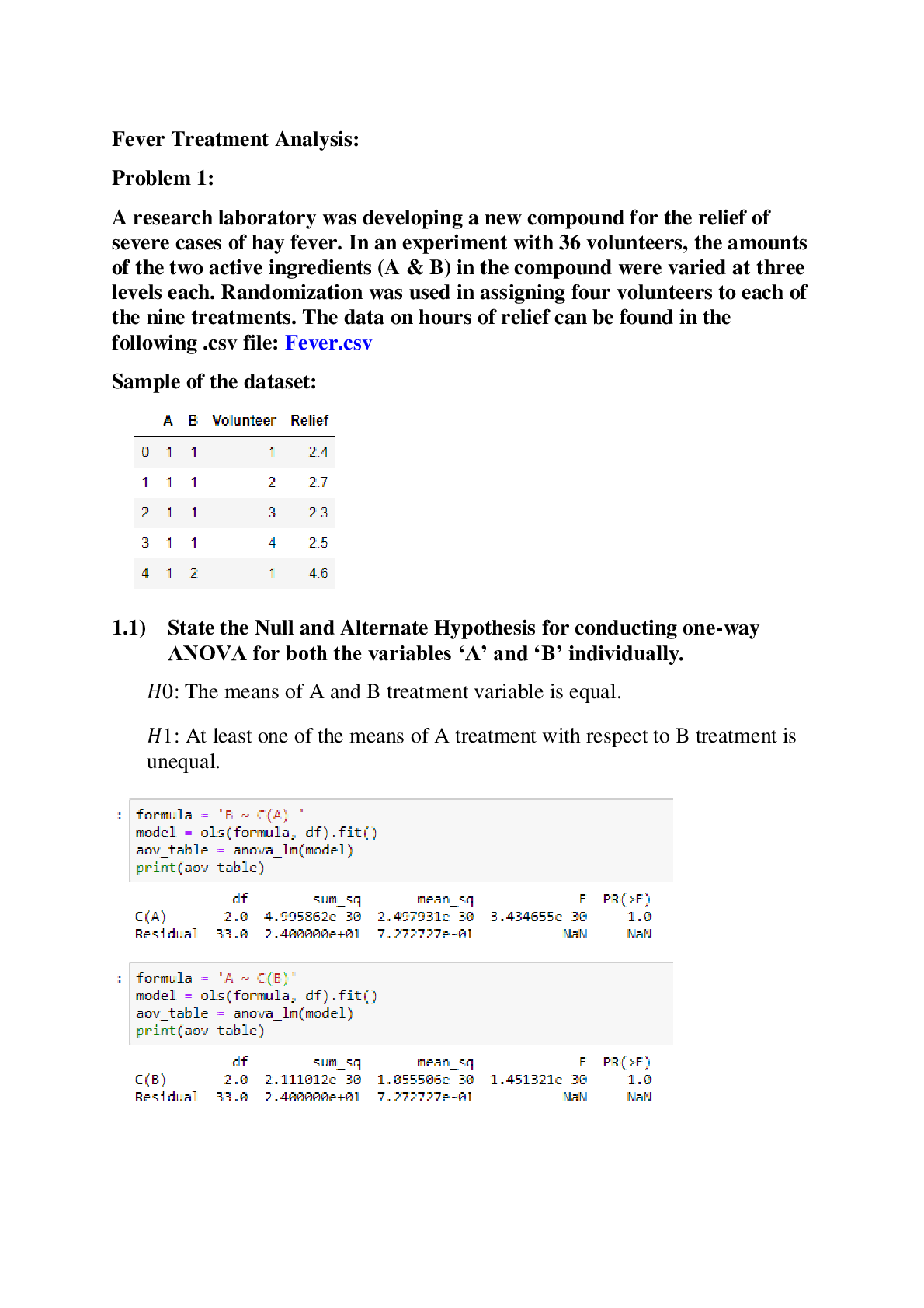

UTILIZATION OF HOT REINJECTION BRINE FOR MORE ENERGY PRODUCTION USING AN ORC SYSTEM AT OLKARIA 1 AU POWER PLANT A RESEARCH PROJECT PRESENTED TO THE DEPARTMENT OF MINING, MATERIALS AND PETROLEUM EN ... GINEERING. MMPE-PRO-20-04 PRESENTED BY: . SUPERVISORS: A research project submitted in partial fulfilment of requirements for the award of the degree of Bachelor of Science in Mining and Mineral Processing Engineering in Jomo Kenyatta University of Agriculture and Technology DECEMBER 2020 DECLARATION. We declare that this report is our original work and to the best of our knowledge, it has not been submitted for the award of any degree in any university or institution. Mutai K. Joshua. Signature: __________________________ Date: _______________ Kemboi K. Peter. Signature: __________________________ Date: _______________ SUPERVISOR’S APPROVAL. We certify that the mentioned students carried out the work detailed in this report under our supervision. 1. Name: Bernard K Rop. Signature: __________________________ Date: ________________ 2. Name: Seroni Anyona. Signature: __________________________ Date: ________________ ABSTRACT. Energy is one of the key driving factors of economy of a country and hence its production and distribution is essential for its effectiveness. Most of the developing countries with higher economic growth rates will directly increase the rate of consumption of the energy. Kenya is among the fast-developing countries and hence the country’s the energy production sectors has been subjected to high demand hence the need to explore more and utilise the sources for highest efficiency achievement possible. KenGen’s Olk I AU geothermal power plant in Kenya employs a single flash condensing turbine type which is comprise Two (2) units each with a capacity of 70MW resulting to a total of 140MW generated from the power plant. Currently, some of the hot water (brine) from the steam separation stations of the power plant is discharged to the surrounding and the rest if re-injected back to the reservoir while still at high temperatures and pressure in which a significant amount of available energy is lost. The untapped amount of energy from the brine renders the single flash steam geothermal power plant a low efficiency production process. The massive flow rates of brine discharged without heat being extracted prompted the research on the development and introduction of the Organic Rankine Cycle (ORC) power plant. The technology is advantageous in generating power from low temperature brine from the geothermal reservoirs but has not been used anywhere in Kenya. The power plant utilizes a working fluid with low boiling point such as refrigerants or hydrocarbons. Research done on ORC shows that its efficiency is dependent on various factors such as proper selection of the working fluid, type of heat exchangers (condenser and evaporator) and turbine used. The research proposal is aiming at designing an ORC suitable for the Olk 1AU power plant based on the flow rates available. TABLE OF CONTENTS DECLARATION. ii ABSTRACT. iii LIST OF FIGURES. vi LIST OF TABLES. vii LIST OF NOMENCLATURE AND ABBREVIATIONS. viii CHAPTER ONE: 1 INTRODUCTION. 1 1.1 Background information. 1 1.2 The Olkaria geothermal system 2 1.2.1 Location and geological setting 2 1.2.2 A brief history of the development 3 2.2.3 Geological overview. 4 1.3 PROBLEM STATEMENT. 7 1.4 OBJECTIVE. 8 1.5 PROBLEM JUSTIFICATION. 8 CHAPTER TWO. 9 LITERATURE REVIEW. 9 2.1INTRODUCTION. 9 2.2 Geothermal energy utilization 10 2.3 geothermal power plant configuration 10 2.3.1 Conventional power plants 11 2.3.2 Binary cycle geothermal power plant. 11 2.4 Organic Rankine Cycle. 12 2.4.1 Working fluids in ORC 12 2.4.2 ORC heat exchangers 13 2.4.3 The ORC turbine 13 2.5 Combined cycle geothermal power plant. 14 CHAPTER 3: 15 METHODOLOGY. 15 3.0 Background. 15 3.2 Working fluid selection. 17 3.3 Heat exchangers design. 18 3.4 Turbine design 19 3.5 conversion of kinetic energy into work 19 3.6 fundamental nozzle energy relations 19 3.4 Data collection procedure. 20 3.5 Results analysis. 20 CHAPTER 4 21 4. DATA ANALYSIS, RESULTS AND DISCUSSION 21 4.0 INTRODUCTION 21 4.1 DATA COLLECTION. 21 4.2 DATA ANALYIS AND RESULTS. 22 4.3 cost analysis 26 CHAPTER FIVE. 27 5.0 CONCLUSION AND RECOMMENDATION. 27 5.1 CONCLUSSION. 27 5.2 RECOMMENDATIONS FOR FUTURE WORK 27 REFERENCES; 28 LIST OF FIGURES. Figure 1: Location of Olkaria geothermal system within the Kenya Rift Valley 2 Figure 2: Location of the geothermal fields, drilled wells and the study area 4 Figure 3: Geological structural map of Olkaria geothermal system 5 Figure 4: General subsurface stratigraphy of Olkaria reservoir 6 Figure 5: Single flashing plant and binary cycle plant combined geothermal power plant.15 Figure 6: Schematic diagram of the Model Organic Rankine Cycle power plant 17 LIST OF TABLES. Table 1: First Semester Work Plan 21 Table 2: Second Semester Work Plan 21 Table 3: Estimated Project budget 22 LIST OF NOMENCLATURE AND ABBREVIATIONS. KenGen –Kenya Electricity Generating Company, LTD. Jkuat - Jomo Kenyatta University of Agriculture and Technology. ORC- Organic Rankine Cycle. OW-Olkaria Well. PTI- Pressure Transmitter Indicator. CHAPTER ONE: INTRODUCTION. 1.1 Background information. Electricity generation from geothermal energy in Kenya is set to increase significantly for the amount of energy fed into the National grid is relatively low. This has been necessitated by the bad weather pattern that has persisted in the last few years and has rendered hydroelectric power generation, from which Kenya uses most of its electricity quite unreliable. To meet this demand, steam production from proven geothermal reservoirs like those within the Olkaria geothermal system will have to be increased, as this will be easier and less costly than to rely on the unexplored prospects. This will call for a more elaborate and advanced reservoir engineering work so as to ensure optimum exploitation. This study was borne out of the need to acquire these advanced skills that will enable us solve some complex reservoir management problems that might arise. 1.2 The Olkaria geothermal system 1.2.1 Location and geological setting Olkaria geothermal system is located in the East African Rift Valley to the south of Lake Naivasha and 120 km northwest of Nairobi. This geothermal system, covering an area more than 120 km2, is associated with a volcano that is one of the several volcanic centres situated within the Central Kenyan Rift amongst which include Longonot, Eburru, Suswa and Menengai, (Figure 1). Figure 1: Location of Olkaria geothermal system within the Kenya Rift Valley (From Muchemi, 1999) 1.2.2 A brief history of the development Exploration of this geothermal resource was initiated by the United Nations and the Government of Kenya in 1956 and has been continuous since 1970. In 1970, Olkaria Geothermal Project was initiated and was jointly financed by UNDP and the Kenya Government. During the same year, further exploration work consisting of geological mapping and geophysical and geochemical surveys as well as more investigations on the two exploration wells began. In 1972, well OW-X2 was coaxed into production through a small diameter pipe at atmospheric pressure and continuously produced for a year before being shut-in Drilling started in 1973 with well OW-1 located to the southeast of the greater Olkaria system. This well was drilled to a depth of 1003 m and did not discharge on its own due to low temperature and permeability. The temperature measured at 1000 m was 126°C and the water rest level was 618 m below the wellhead. The well was stimulated into production by air-lift, but it could not sustain production. Following this unsuccessful result with well OW-1, it was decided to move about 3.5 km to the northeast of this well for drilling of well OW-2. Drilling of well OW-2 gave positive results. It was drilled to 1350 m and encountered a 240°C steam zone at 650 m. Maximum temperature recorded was 280°C at the bottom. Discharge at atmospheric pressure gave 70 – 75 % steam and total flow rate was 9 kg/s at a pressure of 6 bar-abs. It is due to the success in this well that further appraisal and production drilling were done in the vicinity culminating in the 1976 feasibility study for utilisation of geothermal steam for generation of electricity at Olkaria (SWECO and VIRKIR, 1976). The study indicated that development of the geothermal resource was attractive and the authorities decided to construct a 30 MWe power plant of two 15 MWe units with possible extension by addition of a third 15 MWe unit (Svanbjörnsson et. al., 1983). The first unit was brought on line in July 1981, the second in December 1982 and the third in April 1985. Generally, Olkaria geothermal system is now divided into East field, Northeast field, Central field, West field, Northwest field, Southeast field and Domes field (Figure 2 [Show More]

Last updated: 3 years ago

Preview 1 out of 36 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$25.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Apr 13, 2021

Number of pages

36

Written in

All

Additional information

This document has been written for:

Uploaded

Apr 13, 2021

Downloads

0

Views

143