COMPRESSION AND FLEXURE TEST OF CONCRETE LAB REPORT

Experiment No. # 8 Compression and Flexure Test of

Concrete

Keith Pugh Mechanical Engineering Technology

Old Dominion University

August 5, 2020

...

COMPRESSION AND FLEXURE TEST OF CONCRETE LAB REPORT

Experiment No. # 8 Compression and Flexure Test of

Concrete

Keith Pugh Mechanical Engineering Technology

Old Dominion University

August 5, 2020

Old Dominion University Civil Engineering Technology Department

Kaufman Hall, Room 149 Norfolk, VA 23529

Table of Contents

1. Summary 2

2. Procedure 3

3. Equipment 4-5

4. Experiment Requirements 6

5. Required Data 7-9

6. Sample Calculations 10-11

7. Sketches 12-14

8. Conclusions/Analysis 15

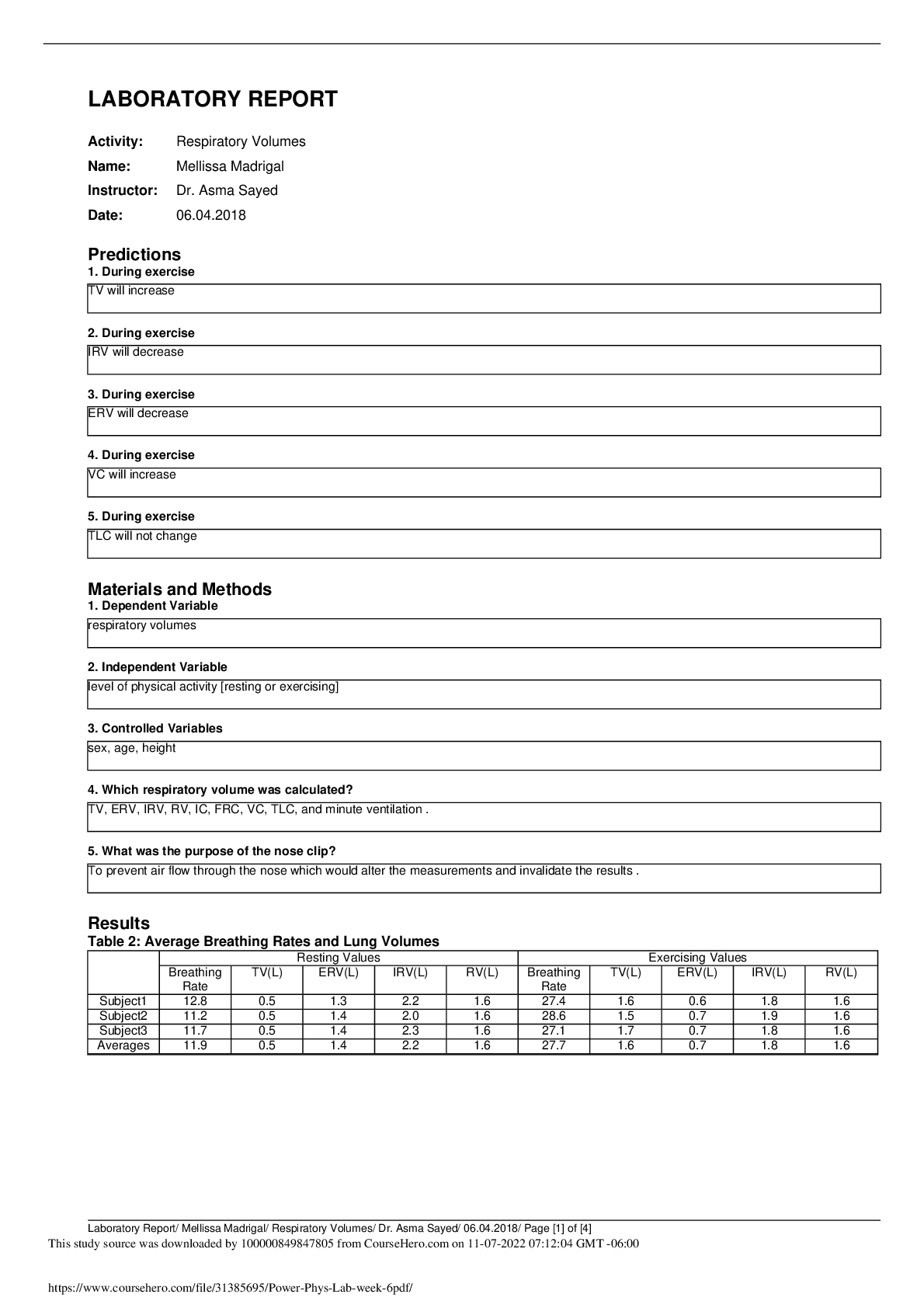

1. Summary

In this experiment we tested the shear strength of metal fasteners in two different applications. One was in a single shear scenario in a lap joint, and the other was in a double shear scenario in a butt joint. The lap joint was joined together with a single bolt though two plates, and the butt joint was joined with four bolts (three in one plate and one in another).

Creating three times the shear tolerance on one end and a single shear tolerance on the other. This experiment showed the amount of force it required to shear the fasteners, showing that the more balanced unified bolted scenario could withstand a strong shear force applied.

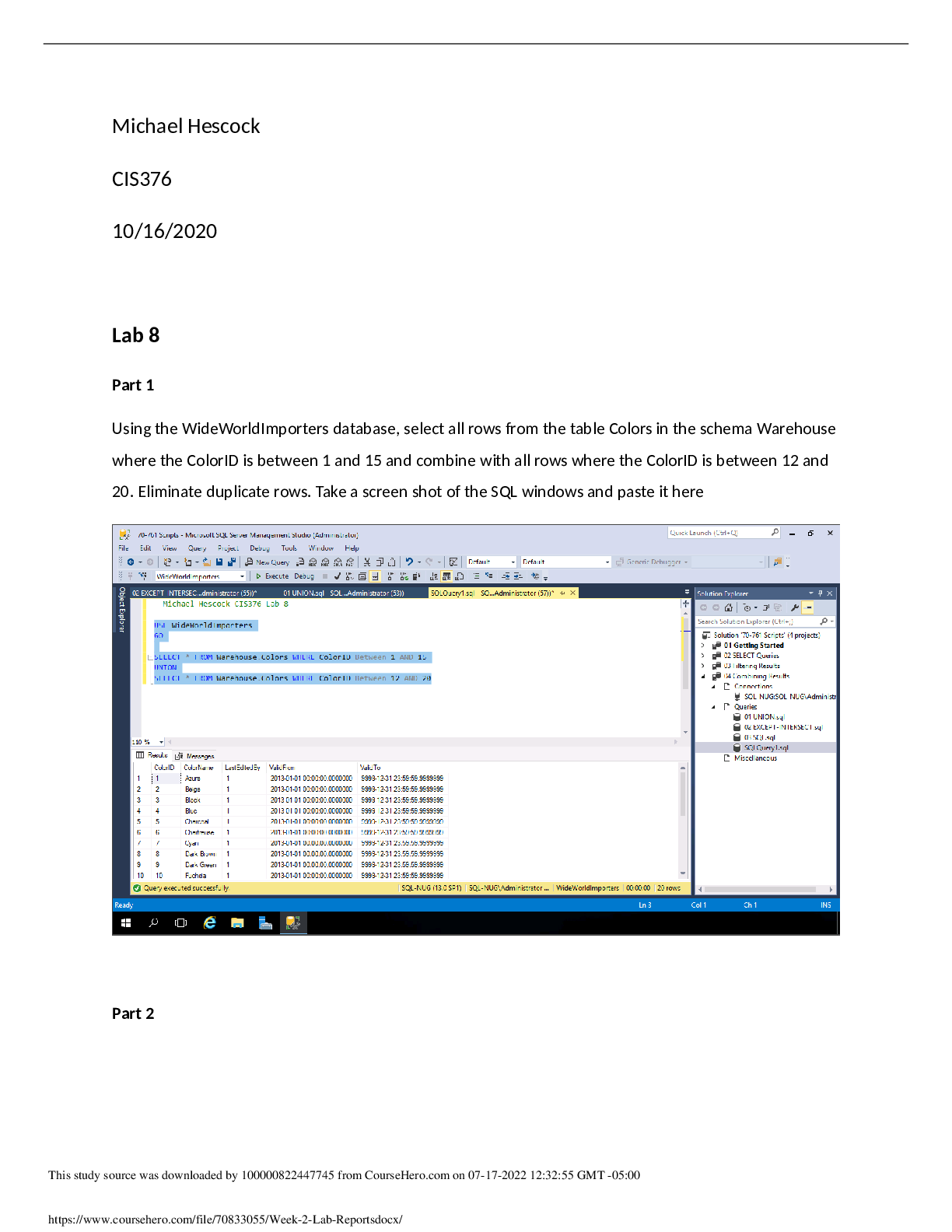

2. Procedure

1. Weigh each of the test cylinders.

2. Pour a quantity of melted capping compound into steel capping mold.

3. Immediately set test cylinder into compound ensuring that cylinder is vertical with mold by pressing cylinder against upper and lower "V" blocks.

4. When compound is set turn cylinder over and cap the opposite side.

5. Remove and allow capped cylinder to set 30 minutes before testing.

6. Take several diameter measurements near center of the cylinder; average the measurements and calculate the cross sectional area.

7. Place test cylinders, one at a time, into concrete compression tester ensuring that mesh cage is secured around specimen.

8. Check with instructor to learn the operation procedure for the concrete compression tester.

9. Apply load to test cylinder until failure occurs.

10. Note highest load carried by the specimen.

11. Discard all broken specimens and sweep the floor.

12. Record dimensions of concrete beam.

13. Place beam supporting block on testing machine ensuring that the loading block is exactly centered between beam supports.

14. Place beam on supporting device ensuring that supports are still at proper spacing.

15. Attach deflectometer to center of beam in accordance with the method given by the instructor.

16. Slowly apply load until obvious beam failure noted by cracks appearing on the tension side of beam.

17. While the beam is being loaded record at least 12 values of load and corresponding deflection.

18. Discard broken specimen and sweep the floor.

[Show More]

.png)

.png)