Critically evaluate the impact of covid 19 pandemic on the management decision making process, given that

the UKM senior management has ignored such impact on their planning for 2020 & beyond.

Manufacturing industry ha

...

Critically evaluate the impact of covid 19 pandemic on the management decision making process, given that

the UKM senior management has ignored such impact on their planning for 2020 & beyond.

Manufacturing industry has been hit in many ways due to the corona pandemic. To begin with, it can

be lower production, due to lower offtake. More and more employees stop coming to work, due to

government directives, thereby reducing the scale of operations, with consequent effect on quality, cost and

production volumes. Over a period, this adversely affects the turn over which slows down to a trickle. The

uncertainties in the logistics leads to a cascading effect transporters struggle to not only place vehicles to not

only place vehicles for loading, they also are under pressure to adjust their quotes for carrying goods, as they

face lower attendance ,with their operational risks increasing steeply.

UKM management felt each business unit needed flexibility and independence to react to rapidly changing

market conditions. UKM believed that if its business units were profit centres, they would be more accountable

for their own financial success. Their strategies and annual performance would be more visible and measurable

as well. This change meant they could sell their devices to external customers using available manufacturing

capacity. UKM could also recover the large development costs for future products and control their destiny. But

due to pandemic situation we cannot estimate the company to be profitable throughout 2020 .

The disruption on manufacturing caused by COVID-19 has severe operational, social and financial

consequences. It is forcing manufacturers to rethink risk management and contingency plans, workforce safety

protocols, manufacturing operations and new ways of working opportunities, all at the same time. So far,

manufacturing leaders have concentrated on solving the immediate challenges required to keep the business

as stable as possible. They’ve formed rapid response teams to gain a better understanding of their production

demand changes, labour support challenges and supply chain ecosystem constraints.

Simultaneously, they need to focus on building a business that is as future-proof as possible using new

technology solutions. This strategy will not only increase resilience, protect operations, and support workers

through the crisis, but will also help sustain a competitive advantage to accelerate business growth once

economies start to rebound.

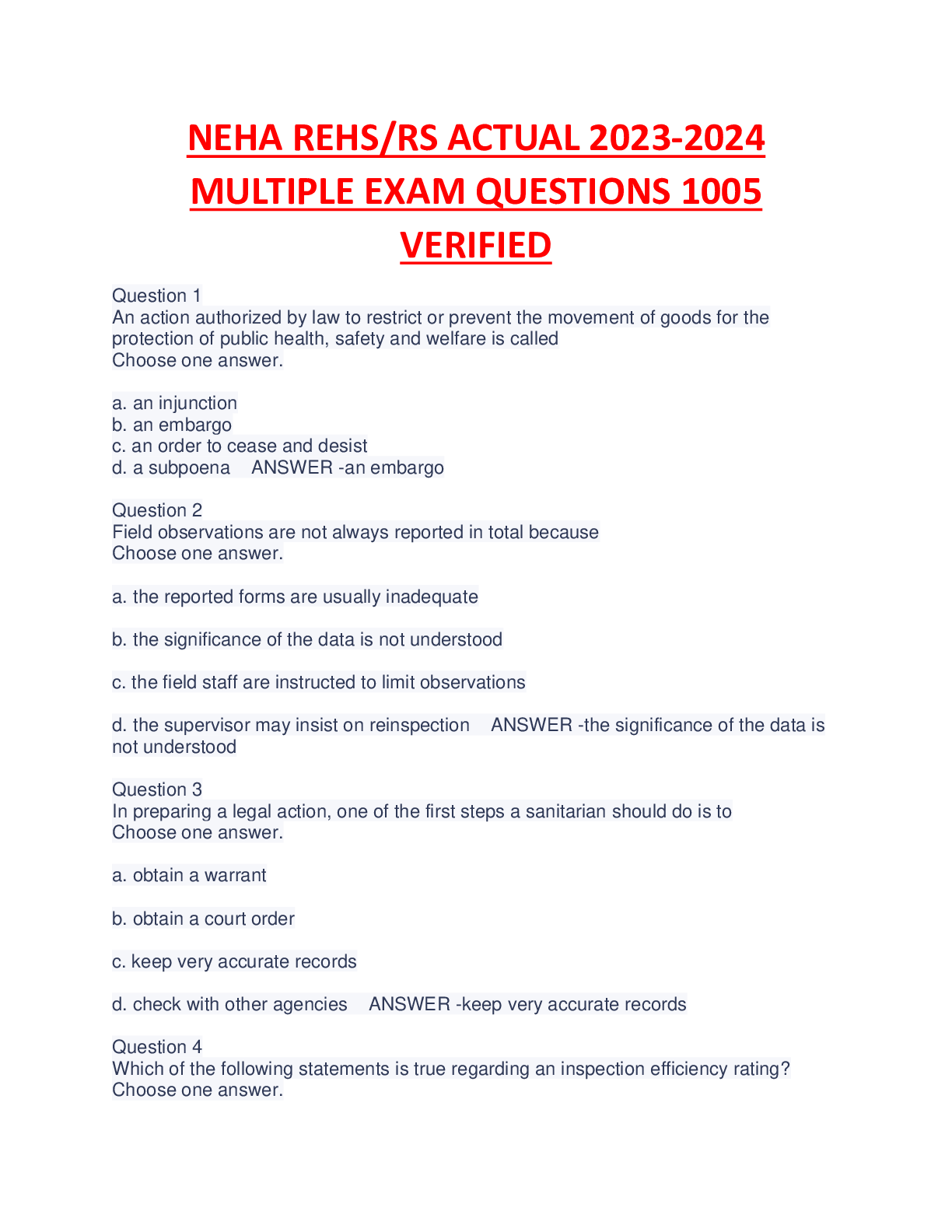

What caused the 2019 SPx512 product cost to drop by £227 after reflecting the ABC review and the new

costing approach? Did spending decrease or just shift?

Activity-based costing (ABC) is a costing method that identifies activities in an organization and assigns the cost

of each activity to all products and services according to the actual consumption by each. This model assigns

more indirect costs into direct costs compared to conventional costing.

According to Nehler ABC provides a company with following criteria:

Better understanding of cost in the organization.

improved communication among units

Constructors become more aware of costs which lead to a cost effective construction and cost

reduction initiative from operative staff.

For the SPx512 developed and manufactured, Sarah, head of UKM new marketing department, believed the

market would require similarly timed price / performance offerings .

As product development was no longer working on any SPx512 performance improvements, Sarah computed

the essential price reductions on the SPx512 following the industry model. The SPx512 would continue at the

£850 price through Q1 2019, then drop to £637.50 at the start of Q2 2019, drop to £425.00 at the start of Q1

2020 and to £318.75 at the start of Q4 2020. Simon Smith, UK manufacturing’s (UKM) director of operations ,

[Show More]