Management > QUESTIONS & ANSWERS > Supply Chain Management (MGO 303) Homework 3. All Questions and Answers. (All)

Supply Chain Management (MGO 303) Homework 3. All Questions and Answers.

Document Content and Description Below

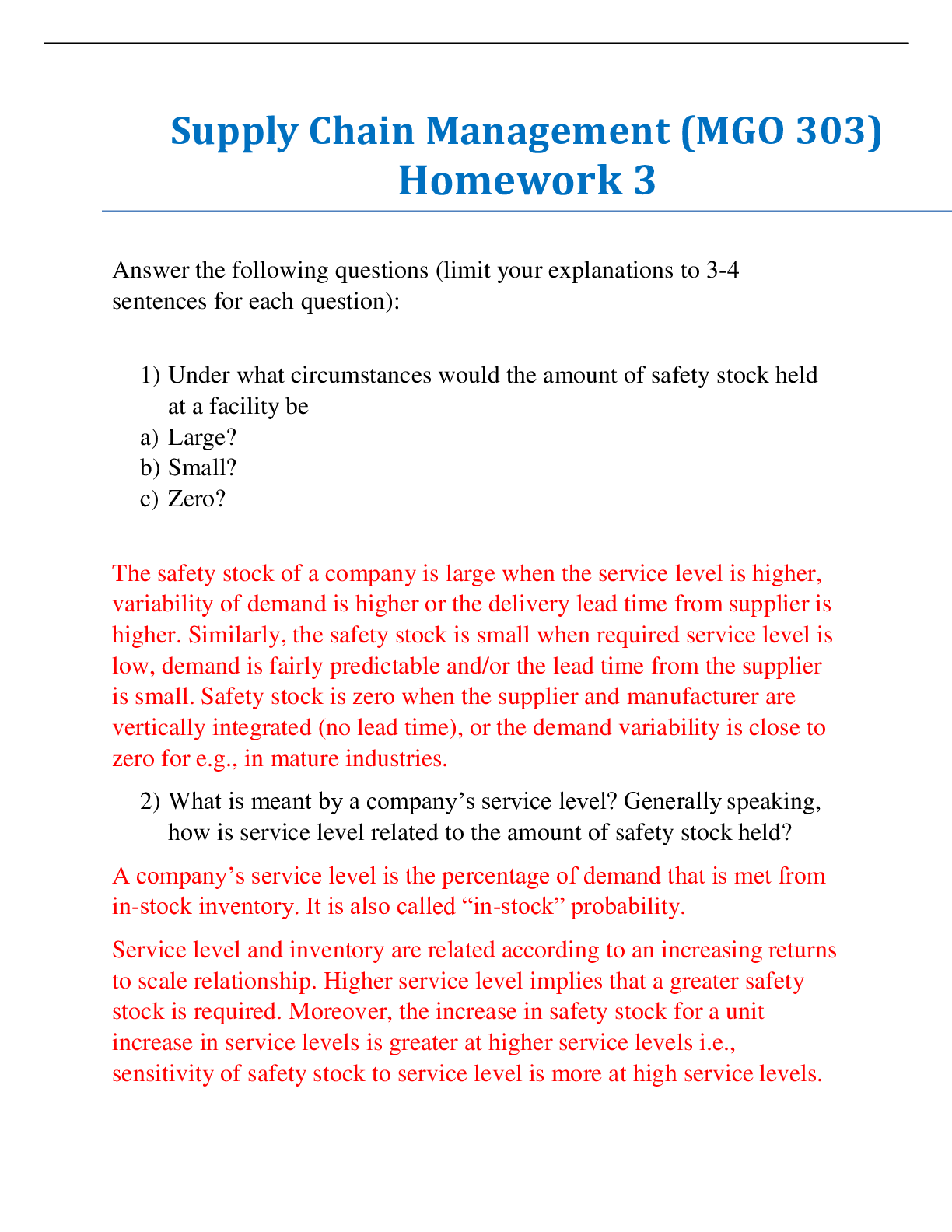

Supply Chain Management (MGO 303) Homework 3 Answer the following questions (limit your explanations to 3-4 sentences for each question): 1) Under what circumstances would the amount of safety st ... ock held at a facility be a) Large? b) Small? c) Zero? 2) What is meant by a company’s service level? Generally speaking, how is service level related to the amount of safety stock held? 3) What is a single-period model and under what circumstances is it appropriate? 4) The optimal stocking level in the single period model can be lower than the expected (or average) demand. True False Explain. 5) Outsourcing/Insourcing: A distributor in the US is considering two suppliers of its popular products sold in the US – one supplier is domestic with a low leadtime (say, one week) and a product price of $1 per unit. The other supplier located in Asia and has a much larger delivery leadtime (say, 2 months) but a lower product price per unit. Give a summary of various factors you would consider in choosing your supplier i.e., under what conditions would you insource vs outsource? (Hint: Consider the relative impact on inventory costs including safety stock, transportation costs, variability of demand in the US etc. in your answer. Assume same service level requirements). 6) A facility has the following sales over a week. Calculate the daily average demand and standard deviation. Day Mon Tue Wed Thu Fri Sat Sun Sales 10 15 23 10 12 15 20 The average daily demand is 10+15+23+10+12+15+20 = 15 (10 − 15)2 + (15 − 15)2 + (23 − 15)2 + (10 − 15)2 + (12 − 15)2 + √ 7 − 1 3) Demand for walnut fudge ice cream at the Sweet Cream Dairy can be approximated by a Normal distribution with a mean of 21 gallons per week and a standard deviation of 3.5 gallons per week. The new manager desires a service level of 90 percent. Lead time is two days, and the dairy is open seven days a week. (Hint: Work in terms of weeks). Answer the following questions: (a) Under a continuous review policy, what reorder point would be consistent with the desired service level? (b) How many days of supply are on hand at the reorder point? (c) If a periodic review policy is used instead of a continuous review system and inventory is reviewed every 3 days, what order size would be needed if the store holds 15 gallons in inventory? (d) What is the order size in part (c) if the store holds 20 gallons in inventory? 4) A manager must set up inventory ordering systems for two new production items P34 and P35. P34 can be ordered at any time, but P35 can be ordered only once every four weeks. The company operates 50 weeks a year, and the weekly usage rates for both items are normally distributed. The manager has gathered the following information about the items: Item P34 Item P35 Average Weekly demand 60 units 70 units Standard Deviation 4 units per week 5.5 units per week Unit Cost $15 $20 Annual Holding cost (as percent of unit cost) 30% 30% Ordering Cost $70 $30 Lead Time 2 weeks 2 weeks Acceptable Stockout risk 2% 2% (a) Describe the inventory policy for each item (b) Compute the order quantity for P34. (c) Compute the order quantity for P35 if 110 units are on hand at the time the order is placed. [Show More]

Last updated: 3 years ago

Preview 1 out of 7 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$9.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Sep 19, 2020

Number of pages

7

Written in

All

Additional information

This document has been written for:

Uploaded

Sep 19, 2020

Downloads

0

Views

186