Health Care > EXAM > NFPA 10 - Standards for Portable Fire Extinguishers 29 Questions with Verified Answers,100% CORRECT (All)

NFPA 10 - Standards for Portable Fire Extinguishers 29 Questions with Verified Answers,100% CORRECT

Document Content and Description Below

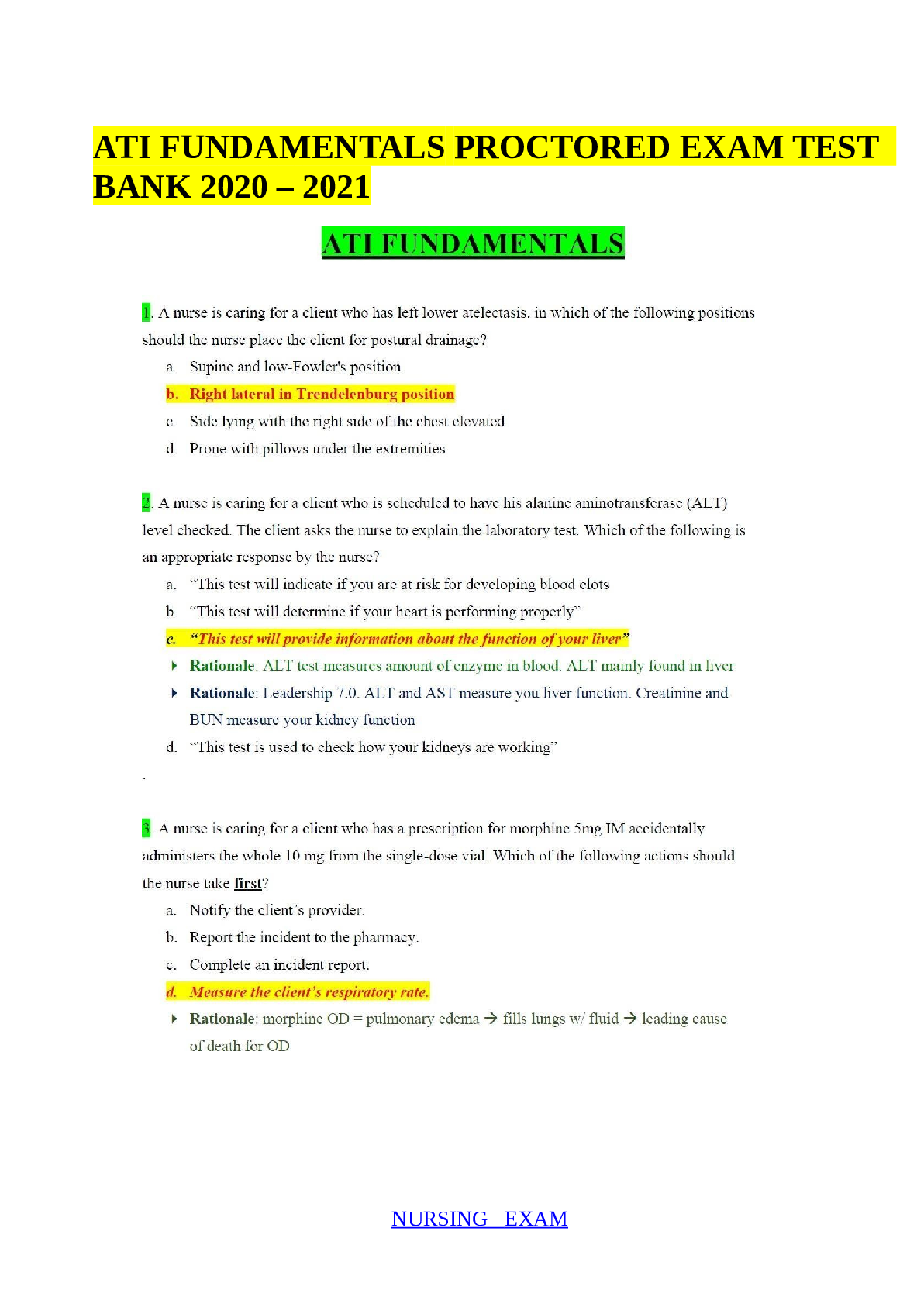

NFPA 10 - Standards for Portable Fire Extinguishers 29 Questions with Verified Answers The A rating is a water equivalency rating. Each A is equivalent to ________ of water. - CORRECT ANSWER Answer ... : 1 1/4 gallons. Note that 4A = 5 gallons of water. The ________ rating is equivalent to the amount of square footage that the extinguisher can cover, handled by a professional. - CORRECT ANSWER Answer: B:C Note that 20 B:C = 20 square feet of coverage. C indicates it is suitable for use on ________ ________ ________. - CORRECT ANSWER Answer: electrically energized equipment. 8.8 Condemning Extinguishers 8.8.1 Fails Test or Examination When a fire extinguisher cylinder, shell, or cartridge fails a hydrostatic pressure test or fails to pass a visual examination as specified in 8.4.2, it shall be condemned or destroyed by the owner or the owner's agent. 8.4.2* Examination of Cylinder Condition Where a fire extinguisher cylinder or shell exhibits one or more of the following conditions, it shall not be hydrostatically tested but shall be condemned or destroyed by the owner or at the owner's discretion: A.8.4.2 A condemned cylinder or fire extinguisher can be destroyed only by its owner or at the owner's discretion. It is strongly recommended that a record be kept of cylinders or fire extinguishers that are recommended to be destroyed. (1)* Where repairs by soldering, welding, brazing, or use of patching compound exist A.8.4.2(1) For welding or brazing on mild steel shells, consult the - CORRECT ANSWER 8.7.3 High-Pressure Cylinders and Cartridges 8.7.3.1 Cylinders or cartridges that pass the hydrostatic test shall be stamped with the retester's identification number and the month and year of the retest per DOT/TC requirements. 8.7.3.2 Stamping shall be placed only on the shoulder, top, head, neck, or foot ring (where provided) of the cylinder or in accordance with 49 CFR 180.213(c)(1). 8.7.4 Hose Assemblies. Hose assemblies that pass a hydrostatic test shall not require recording, labeling, or marking. - CORRECT ANSWER 8.7.2* Low-Pressure Cylinders A.8.7.2 Figure A.8.7.2 provides a guide to the design of a hydrostatic test label. All print should be black on a silver background. 8.7.2.1 Fire extinguisher cylinders of the low-pressure non-DOT type that pass a hydrostatic test shall have the following information recorded on a label: (1) Month and year the test was performed, indicated by a perforation, such as is done by a hand punch (2) Test pressure used (3) Name or initials of the person performing the test and name of the agency performing the test 8.7.2.2 The Label shall meet the following criteria: (1) Sized at a minimum of 2 in. x 3 1/2 in. (51 mm x 89 mm) (2) Affixed by a heatless process (3) Self-destructs when removed from a fire extinguisher cylinder shell (4) Made of a durable, weatherproof material with a pressure-sensitive adhesive 8.7.2.3 In addition to the information in 8.7.2.1, DOT specification cylinder - CORRECT ANSWER 8.7 Recording of Hydrostatic Tests 8.7.1* Records The record of a hydrostatic test shall be maintained by the organization that performed the test until either the expiration of the test period or until the cylinder is again tested, whichever occurs first. A.8.7.1 A record of testing should include, as a minimum, the date of the test, cylinder serial number or extinguisher serial number, model number, cylinder size, test pressure, visual inspection result, cylinder disposition, and initials of the person performing the test. Refer to CGA C-1, "Methods of Hydrostatic Testing of Compressed Gas Cylinders," for a sample form for recording test results. - CORRECT ANSWER 8.6 Test Pressures 8.6.3 Hose Assemblies 8.6.3.1 Carbon Dioxide hose assemblies requiring hydrostatic pressure test shall be tested at 1250 psi (8619 kPa). 8.6.3.2 Dry chemical, dry powder, water, foam, and halogenated agent discharge hose assemblies requiring a hydrostatic pressure test shall be tested at 300 psi (2068 kPa) or at service pressure, whichever is higher. 8.6.3.3 Low-pressure accessory hose used on wheeled extinguishers shall be tested at 300 psi (2068 kPa). 8.6.3.4 High-pressure accessory hose used on wheeled extinguishers shall be tested at 3000 psi (20.68 MPa). - CORRECT ANSWER 8.6 Test Pressures 8.6.1 Low-Pressure Cylinders 8.6.1.1 Stored-Pressure Types Stored-Pressure fire extinguishers shall be hydrostatically tested to the pressure specified on the extinguisher nameplate. 8.6.1.1.1 Where pressure is not specified on the extinguisher nameplate, the extinguisher shall be tested at the factory test pressure, not to exceed three times the extinguisher service pressure. 8.6.1.1.2 Fire extinguishers that are required to be returned to the manufacturer for recharging shall be hydrostatically tested only by the manufacturer. 8.6.2 High-Pressure Cylinders 8.6.2.1 DOT 3A, 3AA, or 3AL cylinders used as carbon dioxide extinguishers or nitrogen cylinders, argon cylinders, or carbon dioxide cylinders that are used with wheeled extinguishers shall be tested at 5/3 the service pressure as stamped into the cylinder. 8.6.2.2 Carbon dioxide fire extinguishers having cylinder specifications ICC3 sha - CORRECT ANSWER 8.5 Testing Procedures 8.5.1 General 8.5.1.1 The pressure in a hydrostatic test of a cylinder shall be maintained for a minimum of 30 seconds, but for a time not less than is required for a complete expansion of the cylinder and to complete the visual examination of the cylinder 8.5.1.2 All valves, internal parts, and hose assemblies shall be removed, and the fire extinguisher shall be emptied before testing. 8.5.1.2.1 On certain dry chemical and dry powder fire extinguishers (cartridge-operated), where the manufacturer recommends that certain internal parts not be removed those parts shall not be removed. 8.5.1.3 All types of extinguishers, except the water type, shall have all traces of extinguishing agents removed from the inside of the extinguisher before they are filled with water. 8.5.1.4 A complete internal and external visual examination shall be conducted before any hydrostatic test. 8.5.1.4.1 The pro - CORRECT ANSWER 8.5 Testing Procedures 8.5.2 Low-Pressure Cylinders 8.5.2.1 The hydrostatic testing of dry chemical and dry powder fire extinguishers having an externally mounted gas cartridge shall have the cartridge and cartridge receiver removed and a plug inserted into the opening. 8.5.2.2 All hose shall be removed from cylinders prior to hydrostatic testing. 8.5.2.3 All stored-pressure extinguishers shall have the valve removed from the cylinder and replaced with a plug prior to the test. 8.5.2.4 All cartridge- or cylinder-operated wheeled extinguishers shall have pressure relief devices removed and replaced with a plug prior to the test. 8.5.2.4.1 The manufacturer's recommendations shall be followed. 8.5.2.5 Any distortion of the cylinder shall be cause for rejection. 8.5.2.6 A drop in pressure of the test gauge, which is an indication of a leak, shall be cause for rejection or retest. 8.5.2.7 Cylinders passing the hy - CORRECT ANSWER 8.5 Testing Procedures 8.5.3 High-Pressure Cylinders 8.5.3.1. The Hydrostatic testing of high-pressure cylinders and cartridges shall be in accordance with the procedures of TC, DOT, and CGA C-1. 8.5.3.2 Cylinders passing the hydrostatic test shall be thoroughly dried internally before being returned to service. 8.5.3.3 If heated air is used to dry the cylinders, the temperature shall not exceed 150F (66C) inside the shell. - CORRECT ANSWER 8.5 Testing Procedures 8.5.4 Hose Assemblies 8.5.4.1 The discharge valve shall be removed from the hose assembly without removal of any hose couplings. 8.5.4.2 The location of all couplings shall be marked prior to the hydrostatic test. 8.5.4.3 The hose shall be completely filled with water before testing. 8.5.4.4 For dry chemical and dry powder types, all traces of dry chemical or dry powder shall be removed prior to testing. 8.5.4.5. The hose assembly shall be placed within a protective cage or device whose design permits visual observation during the test. 8.5.4.6 Pressure shall be applied at a rate of rise such that the test pressure is reached in 1 minute. 8.5.4.7 Test pressure for hose assemblies shall be maintained for a minimum of 1 minute. 8.5.4.7.1 Observations shall be made to detect any distortion or leakage while the hose is pressurized. 8.5.4.7.2 Leakage, distortion, or permanent movement of - CORRECT ANSWER Chapter 8 Hydrostatic Testing 8.1 General 8.1.1 Pressure vessels used as fire extinguishers and specified components of fire extinguishers shall be hydrostatically tested in accordance with this chapter. 8.1.2 Cylinders and cartridges bearing U.S. Department of Transportation (DOT) or Transport Canada (TC) markings shall be retested in accordance with the applicable DOT or TC regulations. 8.1.2.1 Hydrostatic testing shall be performed by persons who are trained in pressure testing procedures and safeguards complying with 7.1.2 and who have testing equipment, facilities, and an appropriate manufacturer's service manual(s) available. 7.1.2 Personnel 7.1.2.1* Persons performing maintenance and recharging of extinguishers shall be certified. A.7.1.2.1 Persons performing maintenance and recharging of extinguishers should meet one of the following criteria: (1) Factory training and certification for the specific ty - CORRECT ANSWER 8.2* Test Equipment A.8.2 This standard permits hydrostatic testing only of pressure vessels used as fire extinguishers and specified components of fire extinguishers. 8.2.1 Pressure Gauges 8.2.1.1 Test pressure gauges shall be certified accurate to +/-0.5 percent, or better, of the full range of the gauge. 8.2.1.2 Test pressure gauges shall be capable of being read to within 1 percent of the test pressure. Interpolation of mid-point between smallest graduations shall be permitted. 8.2.1.3 Test pressure gauges shall be capable of indicating 90 percent to 110 percent of the test pressure. 8.2.1.4 Pressure gauges used on test equipment shall be calibrated at least semiannually. 8.2.1.5 Master gauges or dead weight testers shall be calibrated at least annually. - CORRECT ANSWER 8.2 Test Equipment 8.2.2 Drying Equipment 8.2.2.1 All hydrostatically tested cylinders and apparatus, except water-type extinguishers, shall be thoroughly dried after testing. 8.2.2.2 The temperature used for drying shall not exceed 150F (66C) inside the shell. 8.2.3 Test Equipment for High-Pressure Cylinders The equipment for hydrostatic testing of high-pressure cylinders and cartridges (DOT 3 series) shall meet the specifications of CGA C-1, "Methods of Hydrostatic Testing of Compressed Gas Cylinders." 8.2.4 Test Equipment for Low-Pressure Cylinders and Hose Assemblies (Proof Pressure Test) 8.2.4.1 Cylinders and hose assemblies shall be tested within a protective shield that permits visual observation while under pressure for leaks, bulges, and other harmful defects. 8.2.4.2 A hydrostatic test pump, hand- or power-operated, shall be capable of producing not less than 150 percent of the test pressure and shal - CORRECT ANSWER 8.3 Frequency 8.3.1 General. At intervals not exceeding those specified in Table 8.3.1, fire extinguishers shall be hydrostatically retested. ____________________________________________________________ Table 8.3.1 Hydrostatic Test Intervals for Extinguishers Extinguisher Type Stored-pressure water, water mist, loaded stream, and/or antifreeze - 5 years Wetting Agent - 5 years AFFF(aqueous film-forming foam) - 5 years FFFP(film-forming fluoroprotein foam) - 5 years Dry chemical with stainless steel shells - 5 years Carbon Dioxide - 5 years Wet chemicals - 5 years Dry chemicals, stored-pressure, with mild steel shells, brazed brass shells, or aluminum shells - 12 years Dry chemical, cartridge- or cylinder-operated, with mild steel shells - 12 years Halogenated agents - 12 years Dry powder, stored-pressure, cartridge- or cylinder-operated, with mild steel shells - 12 years -------------------------------- - CORRECT ANSWER 8.3 Frequency 8.3.2 Cylinders and Cartridges 8.3.2.1 Nitrogen cylinders, argon cylinders, carbon dioxide cylinders, or cartridges used for inert gas storage that are used as expellants for wheeled fire extinguishers and carbon dioxide extinguishers shall be hydrostatically tested every 5 years. 8.3.2.1.1 Cylinders (except those charged with carbon dioxide) complying with 49 CFR 180.209(b) shall be permitted to be hydrostatically tested every 10 years in lieu of the requirement in 8.3.2.1 8.3.2.2 Nitrogen cartridges, argon cartridges, and carbon dioxide cartridges used as expellants for hand portable fire extinguishers that have DOT or TC markings shall be hydrostatically tested or replaced according to the requirements of DOT or TC. 8.3.2.2.1 DOT 3E cartridges or TC 3EM cartridges shall be exempt from periodic hydrostatic retest. - CORRECT ANSWER 8.3 Frequency 8.3.3. Hose Assemblies 8.3.3.1 A hydrostatic test shall be performed on fire extinguisher hose assemblies equipped with a shutoff nozzle at the end of the hose. 8.3.3.2 High-Pressure and Low-Pressure accessory hose (other than agent discharge hose) used on wheeled extinguishers shall be hydrostatically tested. 8.3.3.3 The test interval for 8.3.3.1 and 8.3.3.2 shall be the same as that specified for the fire extinguisher or fire extinguisher agent cylinder on which the hose is installed. - CORRECT ANSWER 8.4 Extinguisher Examination 8.4.1 General. If, at any time, a fire extinguisher shows evidence of dents, mechanical injury, or corrosion to the extent as to indicate weakness, it shall be condemned or hydrostatically retested subject to the provisions of 8.4.2 and Section 8.8. 8.8 Condemning Extinguishers 8.8.1 Fails Test or Examination When a fire extinguisher cylinder, shell, or cartridge fails a hydrostatic pressure test or fails to pass a visual examination as specified in 8.4.2, it shall be condemned or destroyed by the owner or the owner's agent. 8.4.2* Examination of Cylinder Condition Where a fire extinguisher cylinder or shell exhibits one or more of the following conditions, it shall not be hydrostatically tested but shall be condemned or destroyed by the owner or at the owner's discretion: A.8.4.2 A condemned cylinder or fire extinguisher can be destroyed only by its owner or at the owner's discreti - CORRECT ANSWER Chapter 7 Inspection, Maintenance, and Recharging 7.1* General A.7.1 This chapter is concerned with the rules governing inspection, maintenance, and recharging of fire extinguishers. These factors are of prime importance in ensuring operation at the time of a fire. The procedure for inspection and maintenance of fire extinguishers varies considerably. Minimal knowledge is necessary to perform a monthly "quick check" or inspection in order to follow the inspection procedures as outlined in Section 7.2. 7.1.1. Responsibility. The owner or designated agent or occupant of a property in which fire extinguishers are located shall be responsible for inspection, maintenance, and recharging. (See 7.1.2) 7.1.2 Personnel. 7.1.2.1* Persons performing maintenance and recharging of extinguishers shall be certified. A.7.1.2.1 Persons performing maintenance and recharging of extinguishers should meet one of the following criter - CORRECT ANSWER 7.2 Inspection 7.2.1 Inspection Frequency 7.2.1.1* Fire extinguishers shall be manually inspected when initially placed in service. A.7.2.1.1 Frequency of fire extinguisher inspections should be based on the need of the area in which fire extinguishers are located. The required monthly inspection is a minimum. 7.2.1.2* Fire extinguishers and Class D extinguishing agents shall be inspected either manually or by means of an electronic monitoring device/system at intervals not exceeding 31 days. A.7.2.1.2 Inspections should be performed on extinguishers 12 times per year, at least once per month. 7.2.1.2.1 Fire extinguishers and Class D extinguishing agents shall be inspected at least once per calendar month. 7.2.1.3* Fire extinguishers and Class D extinguishing agents shall be manually inspected daily or weekly when conditions exist that indicate the need for more frequent inspections. A.7.2.1.3 Inspections sho - CORRECT ANSWER 7.2.2.3 Inspection Procedure for Containers of Class D Extinguishing Agent. Periodic inspection of containers of Class D extinguishing agent used to protect Class D hazards shall include verification of at least the following: (1) Located in designated place (2) No obstruction to access to visibility (3) Lid is sealed (4) Fullness by hefting or weighing (5) No obvious physical damage to container 7.2.3 Corrective Action. When an inspection of any fire extinguisher reveals a deficiency in any of the conditions in 7.2.2 or 7.2.2.2, immediate corrective action shall be taken. 7.2.2 Inspection Procedures. Periodic inspection or electronic monitoring of fire extinguishers shall include a check of at least the following items: (1) Location in designated place (2) No obstruction to access or visibility (3) Pressure gauge reading or indicator in the operable range or position (4) Fullness determined by weighing or heftin - CORRECT ANSWER 7.2.4 Inspection Record Keeping. 7.2.4.1 Manual Inspection Records. 7.2.4.1.1 Where manual inspections are conducted, records for manual inspections shall be kept on a tag or label attached to the fire extinguisher, on an inspection checklist maintained on file, or by an electronic method. 7.2.4.1.2 Where manual inspections are conducted, the month and year the manual inspection was performed and the initials of the person performing the inspection shall be recorded. 7.2.4.1.3 Personnel making manual inspections shall keep records of all fire extinguishers inspected, including those found to require corrective action. 7.2.4.1.4 Records for manual inspection shall be kept to demonstrate that at least the last 12 monthly inspections have been performed. 7.2.4.2 Electronic Inspection Records. 7.2.4.2.1 Where electronically monitored systems are employed for inspections, records shall be kept for fire extinguisher - CORRECT ANSWER 7.3 Extinguisher Maintenance 7.3.1* Maintenance Procedures. Where required by another section of this standard, maintenance procedures shall include the procedures detailed in the manufacturer's service manual and a thorough examination of the basic elements of the fire extinguisher, including the following: (1) Mechanical parts of all fire extinguishers (2) Extinguishing agent (3) Expelling means (4) Physical condition A.7.3.1 The annual maintenance of a fire extinguisher requires the services of a trained and certified technician who has the proper tools, listed parts, and appropriate manufacturer's service manual. Maintenance of fire extinguishers should not be confused with inspection, which is a quick check of the extinguishers that is performed at least every 30 days. Because the detailed maintenance procedures for various extinguisher types and models differ, the procedures specified within service manuals - CORRECT ANSWER 7.3 Extinguisher Maintenance A.7.3.1 Continued The following list is a sample of maintenance procedures and checks that are commonly associated with pressurized-water-type hand portable fire extinguishers: (1) Visually examine the extinguisher for damage by removing the extinguisher from the hanger, bracket, or cabinet, and visually examine the extinguisher for damage, including pressure gauge, cylinder dents, repairs, general corrosion, hose or nozzle threads, handles, and levers. (2) Verify that the hanger, bracket, or cabinet is the proper one for the extinguisher. (3) Verify that the hanger, bracket, or cabinet is secure, undamaged, and properly mounted. (4) Verify that the nameplate operating instructions are legible and facing outward. (5) Confirm that the extinguisher model is not subject to recall and is not obsolete. (6) Check the extinguisher records to determine hydrostatic test intervals. (7) Verify th - CORRECT ANSWER 7.3 Extinguisher Maintenance 7.3.2 Annual External Examination of All Extinguishers 7.3.2.1 Physical Condition. An annual external visual examination of all fire extinguishers shall be made to detect obvious physical damage, corrosion, or nozzle blockage to verify that the operating instructions are present, legible, and facing forward, and that the HMIS information is present and legible, and to determine if a 6-year interval examination or hydrostatic test is due. 7.3.2.2* Seals or Tamper Indications. At the time of the maintenance, the tamper seal of a rechargeable fire extinguisher shall be removed by operating the pull pin or locking device. A.7.3.2.2 Where a safety seal or tamper indicator is missing, it can be evidence that the fire extinguisher has been used and, therefore, should be removed from service. Extreme caution should be exercised before replacing a tamper seal on a nonrechargeable fire extingui - CORRECT ANSWER 7.3.3 Annual Internal Examination of Certain Types of Extinguishers 7.3.3.1* Maintenance Intervals. Fire extinguishers shall be internally examined at intervals not exceeding those specified in Table 7.3.3.1. A.7.3.3.1 Persons performing maintenance operations usually come from two major groups: (1) Fire extinguisher service agencies (2) Trained industrial safety or maintenance personnel Fire extinguishers owned by individuals are often neglected because a periodic follow-up program is not planned. It is recommended that such owners become familiar with their fire extinguishers so they can detect telltale warnings during inspection that suggest the need for maintenance. When maintenance is indicated, it should be performed by trained pe4rson having proper equipment. (See 7.1.2.2.) 7.1.2.2 Persons performing maintenance and recharging of extinguishers shall be trained and shall have available the appropriate manu - CORRECT ANSWER 7.3.4* Annual Maintenance Record Keeping A.7.3.4 In addition to the required tag or label, a permanent file record should be kept for each fire extinguisher. This file record should include the following information, as applicable: (1) Maintenance date and the name of the person and the agency performing the maintenance (2) Date of the last recharge and the name of the person and the agency performing the recharge (3) Hydrostatic retest date and the name of the person and the agency performing the hydrostatic test (4) Description of dents remaining after passing of the hydrostatic test (5) Date of the 6-year maintenance for stored-pressure dry chemical and halogenated agent types (See 7.3.6.) 7.3.6 Six-Year Internal Examination of Certain Types of Extinguishers. Every 6 years, stored-pressure fire extinguishers that require a 12-year hydrostatic test shall be emptied and subjected to the applicable internal and ex - CORRECT ANSWER [Show More]

Last updated: 2 years ago

Preview 1 out of 17 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Also available in bundle (1)

Click Below to Access Bundle(s)

NFPA 10 fire extinguishers Exam ( 34 Sets) Questions with Verified Answers,100% CORRECT

NFPA 10 Portable Fire Extinguishers 71 Questions with Verified Answers,NFPA 10 Exam 34 Questions with Verified Answers,NFPA 10 Standard for Portable Fire Extinguishers 60 Questions with Verified Answe...

By securegrades 2 years ago

$35

34

Reviews( 0 )

$7.50

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Dec 10, 2023

Number of pages

17

Written in

All

Additional information

This document has been written for:

Uploaded

Dec 10, 2023

Downloads

0

Views

236