This document contains my own solutions to the problems proposed at the

end of each chapter of the book "Process Modelling, Simulation and Control

for Chemical Engineers" Second Edition, by William L. Luyben. As such,

...

This document contains my own solutions to the problems proposed at the

end of each chapter of the book "Process Modelling, Simulation and Control

for Chemical Engineers" Second Edition, by William L. Luyben. As such, I

can’t guarantee that the proposed solutions are free from errors. Think about

them as a starting point for developing or as a means of checking your own

solutions. Any comments or corrections will be appreciated. Contact me at

[email protected]

The computer programs developed for this chapter (Matlab) are available

at:

https://www.dropbox.com/

sh/zknqiqgfynqafxj/AAB07C-RHQ J7hkUTZkDnvaTa?dl=0

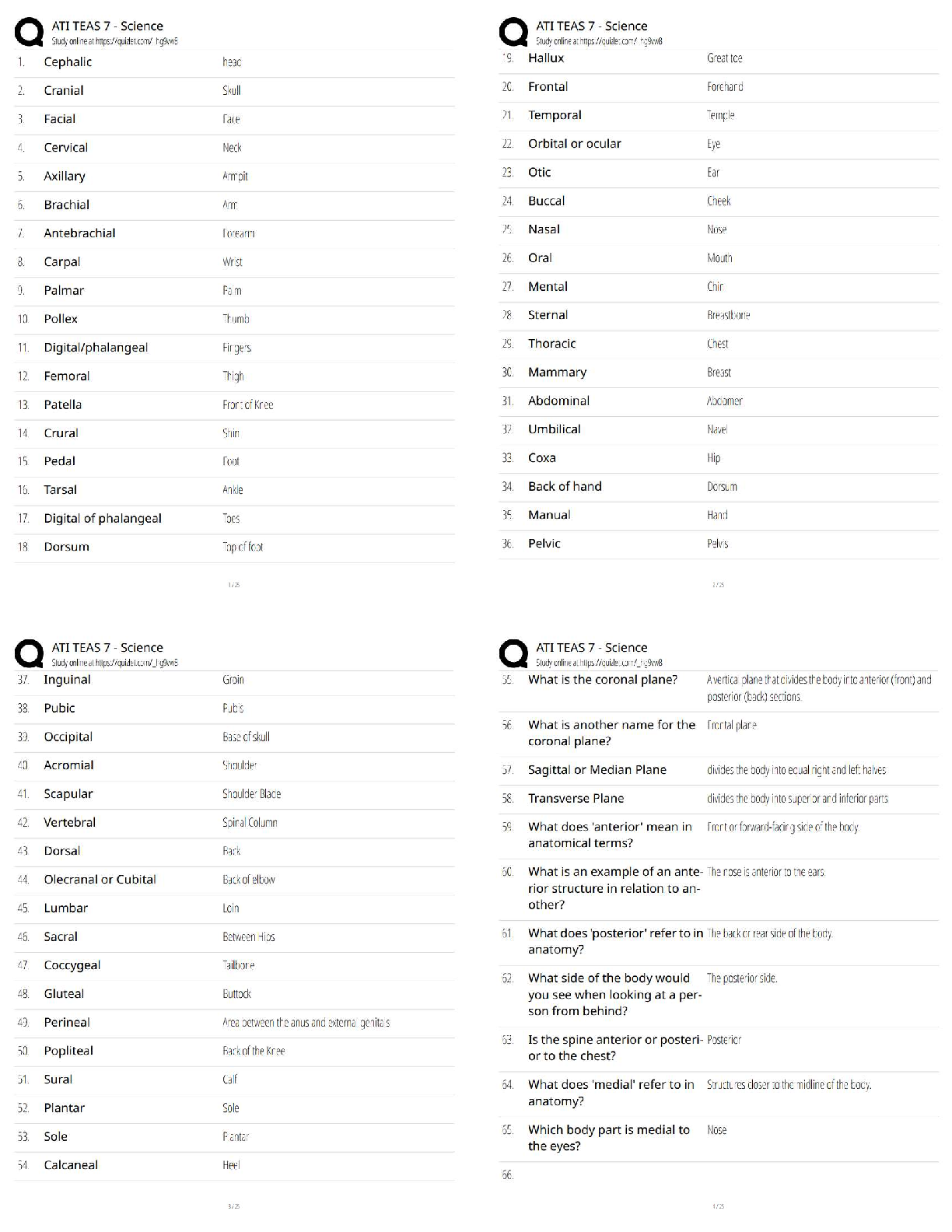

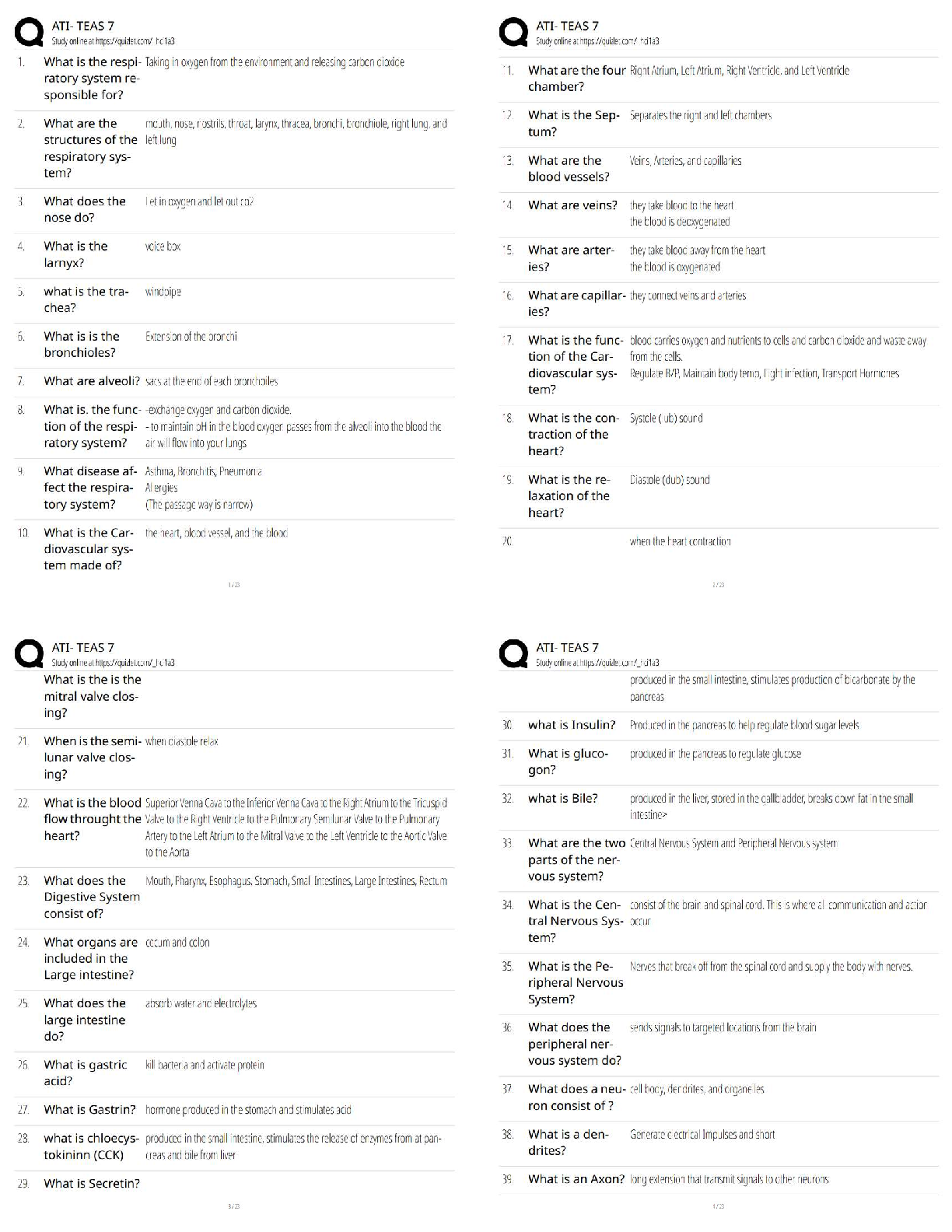

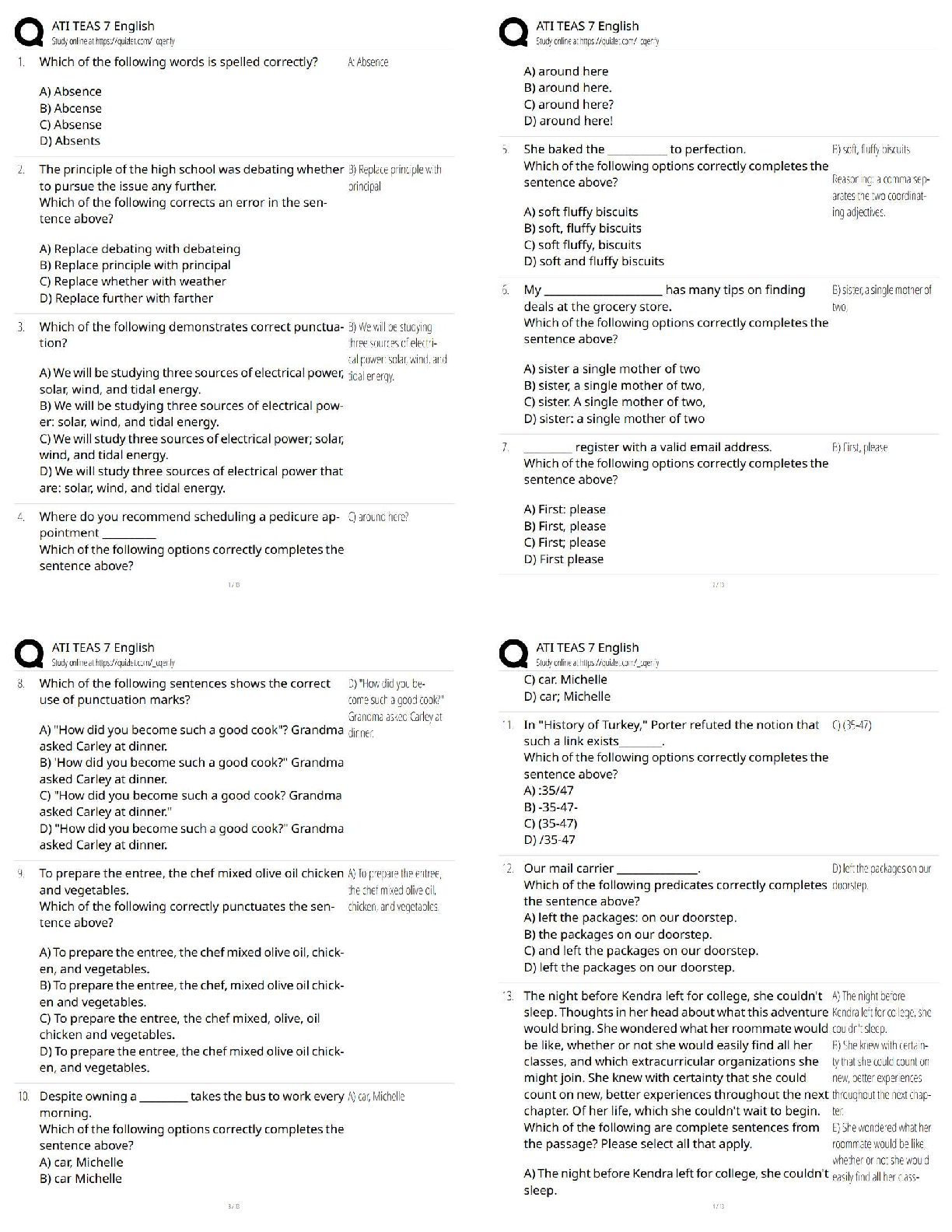

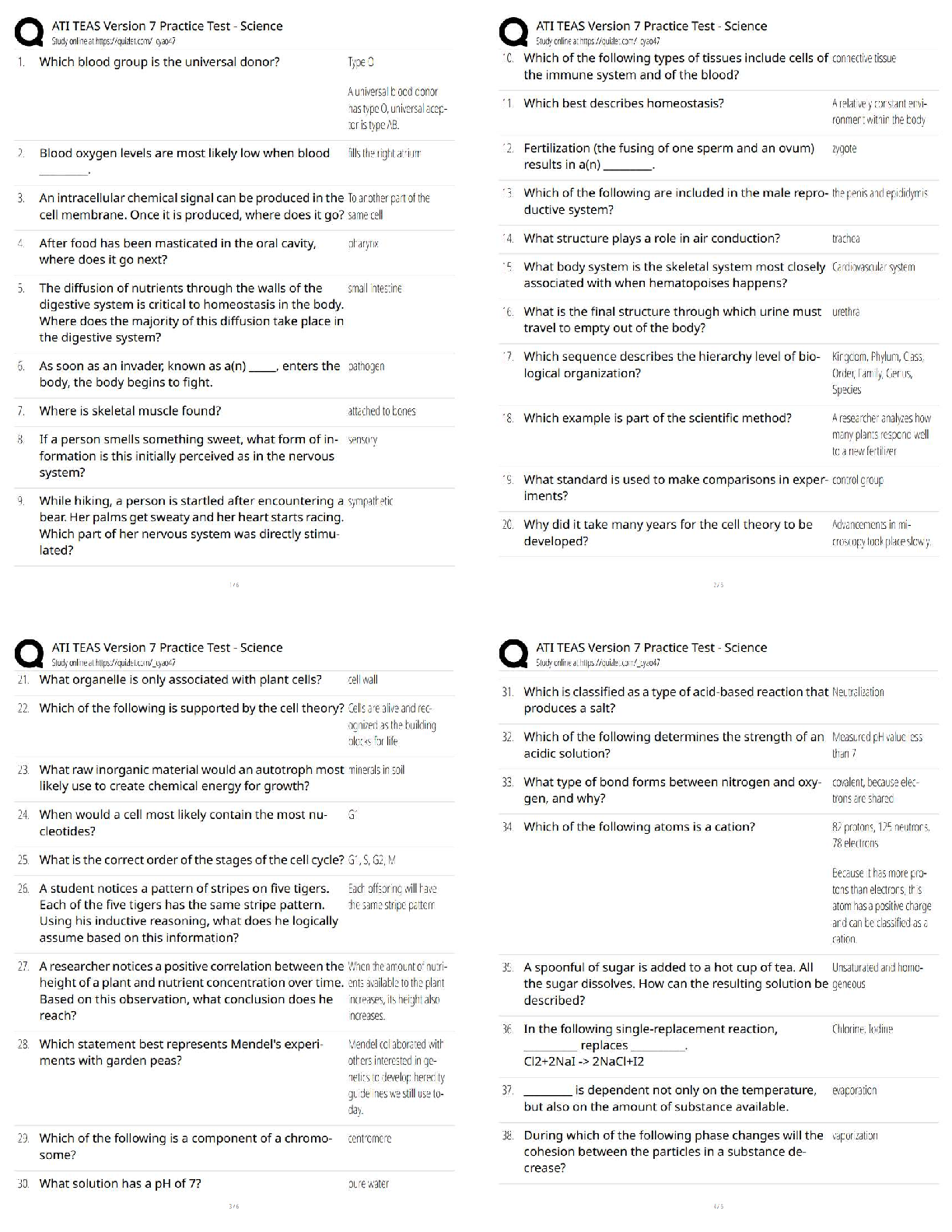

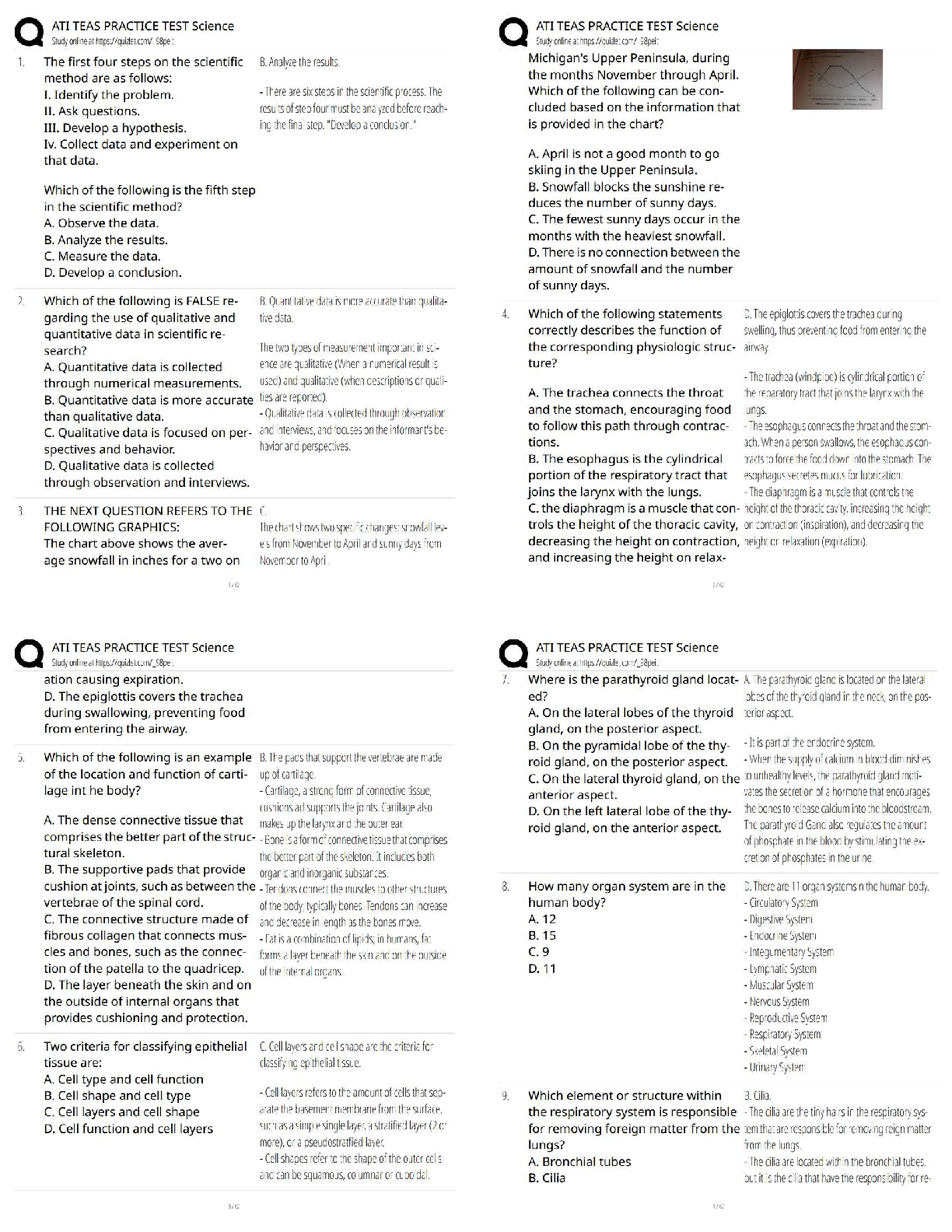

Problem 14

Solve the ODE derived in Problem 3.4 to show that the concentration C in

Grandpa McCoy’s batch of Liquid Lightning is:

C(t) = C0(1 −kte−kt)

Problem 15

Suicide Sam slipped his 2000 lbm hot rod into neutral as he came over the crest

of a mountain at 55 mph. In front of him the constant downgrade dropped 2000

feet in 5 miles, and the local acceleration of gravity was 31.0 ft=s2.

Sam maintained a constant 55 mph speed by riding his brakes until they

heated up to 600◦F and burned up. The brakes weighed 40 lbm and had a heat

capacity of 0.1 BT U=lbm ◦F. At the crest of the hill they were at 60 ◦F.

Heat was lost from the brakes to the air, as the brakes heated up, at a rate

proportional to the temperature difference between the brake temperature and

the air temperature. The proportionality constant was 30 BT U=h ◦F.

Assume that the car was frictionless and encountered negligible air resistance.

1. At was distance down the hill did Sam’s brakes burn up?

2. What speed did his car attain by the time it reached the bottom of the

hill?

Problem 16

A farmer fills his silo with chopped corn (Figure 1). The entire corn plant

(leaves, stem, and ear) is cut up into small pieces and blown into the top of the

cylindrical silo at a rate W0. This is similar to a fed-batch chemical reaction

system.

The diameter of the silo is D and its height is H. The density of the chopped

corn in the silo varies with the depth of the bed. The density ρ at a point that

has z feet of material above it is:

ρ(z) = ρ0 + βz

where ρ0 and β are constants. 1. Write the equations that describe the system and show how the height of

the bed h(t) varies as a function of time.

2. What is the total weight of corn fodder that can be stored in the silo? Problem 17

Two consecutive, first-order reactions take place in a perfectly mixed, isothermal

batch reactor:

A −! k1 B −! k2 C

Assuming constant density, solve analytically for the dynamic changes in

the concentrations of components A and B in the situation where k1 = k2. The

initial concentration of A at the beginning of the batch cycle is CA0. There is

initially no B or C in the reactor.

What is the maximum concentration of component B that can be produced

and at what point in time does it occur? Problem 18

The same reactions considered in Problem 17 are now carried out in a single,

perfectly mixed, isothermal continuous reactor. Flow rates, volume and densities are constant.

1. Derive a mathematical model describing the system.

2. Solve for the dynamic change in the concentration of component A, CA,

if the concentration of A in the feed stream is constant at CA0 and the

initial concentrations of A, B and C at time equal zero are CA(0) = CA0

and CB(0) = CC(0) = 0.

3. In the situation where k1 = k2, find the value of holdup time (τ = V=F)

that maximizes the steady state ratio of CB=CA0. Compare this ratio

with the maximum found in Problem 17. Problem 19

The same consecutive reactions considered in Problem 18 are now carried out in

two perfectly mixed continuous reactors. Flow rate and densities are constant.

The volumes of the two tanks (V) are the same and constant. The reactors

operate at the same constant temperature.

1. Derive a mathematical model describing the system.

2. If k1 = k2, find the value of the hold up time (τ = V=F ) that maximizes

the steadystate ratio of concentration of component B in the product to

the concentration of reactant A in the feed Problem 20

A vertical, cylindrical tank is filled with well water at 65◦F. The tank is insulated at the top and bottom but is exposed on its vertical sides to cold 10◦F

night air. The diameter of the tank is 2 feet and its height is 3 feet. The overall

heat transfer coefficient is 20 BT U=h ◦F ft2. Neglect the metal wall of the tank

and assume that the water in the tank is perfectly mixed.

1. Calculate how many minutes it will be until the first crystal of ice is

formed.

2. How long will it take to completely freeze the water in the tank? The heat

of fusion of water is 144 BT U=lbm. Problem 21

An isothermal, first-order, liquid-phase, reversible reaction is carried out in a

constant-volume, perfectly mixed continuous reactor.

A −! k1 B

B −! k2 A

The concentration of product B is zero in the feed and in the reactor is CB.

Feed rate is F.

1. Derive a mathematical model describing the dynamic behaviour of the

system.

2. Derive the steadystate relationship between CA and CA0. Show that the

conversion of A and the yield of B decrease as k2 increases.

3. Assuming that the reactor is at this steadystate concentration and that a

step change is made in CA0 to (CA0 + ∆CA0), find the analytical solution

that gives the dynamic response of CA(t). Problem 22

An isothermal, first order, liquid phase, irreversible reaction is conducted in a

constant volume batch reactor.

A −! k1 B

The initial concentration of reactant A at the beginning of the batch is CA0.

The specific reaction rate k decreases with time because of catalyst degradation:

k = k0e−βt.

1. Solve for CA(t).

2. Show that in the limit as β ! 0, CA(t) = CA0e−k0t.

3. Show that in the limit as β ! 1, CA(t) = CA0. Problem 23

There are 3460 pounds of water in the jacket of a reactor that are initially at

145◦F. At time equal zero, 70◦F cooling water is added to the jacket at a

constant rate of 416 pounds per minute. The holdup of water in the jacket

is constant since the jacket is completely filled with water and excess water is

removed from the system on pressure control as cold water is added. Water in

the jacket can be assumed to be perfectly mixed.

1. How many minutes does it take the jacket water to reach 99◦F if no heat

is transferred into the jacket?

2. Suppose a constant 362000 BTU/h of heat is transferred into the jacket

from the reactor, starting at time equal zero when the jacket is at 145◦F.

How long will it take the jacket water to reach 99◦F if the cold water

addition rate is constant at 416 pounds per minute? Problem 24

Hay dries, after being cut, at a rate which is proportional to the amount of

moisture it contains. During a hot (90◦F) July summer day, this proportionality constant is 0.30 h−1. Hay cannot be baled until it has dried down to no

more than 5 % moisture. Higher moisture levels will cause heating and mold

formation, making it unsuitable for horses.

The effective drying hours are from 11:00 a.m. to 5:00 p.m. If hay cannot

be baled by 5.00 p.m. it must stay in the field overnight and picks up moisture

from the dew. It picks up 25 percent of the moisture that is lost during the

previous day.

If the hay is cut at 11:00 a.m. Monday morning and contains 40 wt %

moisture at the moment of cutting, when can it be baled?Problem 25

Process liquid is continuously fed into a perfectly mixed tank in which it is

heated by a steam coil. Feed rate F is 50000 lbm=h of material with a constant

density ρ of 50 lbm=ft3 and heat capacity Cp of 0.5 BT U=lbm ◦F. Holdup in

the tank V is constant at 4000 lbm. Inlet feed temperature T0 is 80 ◦F.

Steam is added at a rate S lbm=h that heats the process liquid up to temperature T. At the initial steadystate, T is 190◦F. The latent heat of vaporization

λs of the steam is 900 BT U=lbm

.png)

.png)

.png)

.png)