Table of Contents

1. Summary …………………………………………….…………………………… 2

2. Procedure ……….………………………………………………………………… 2

3. Equipment ……………………..………………….……………………………… 3

4. Experiment Requirements ….……..………………………………………………. 3

5. Requi

...

Table of Contents

1. Summary …………………………………………….…………………………… 2

2. Procedure ……….………………………………………………………………… 2

3. Equipment ……………………..………………….……………………………… 3

4. Experiment Requirements ….……..………………………………………………. 3

5. Required Data ……………..…….………………….…………………………….. 4-6

6. Sketches… ……………..…….……………….…………………………………… 6-16

7. Conclusions/Analysis …………………………….………………………………. 17

8. Appendix 1: Lab Equipment

2

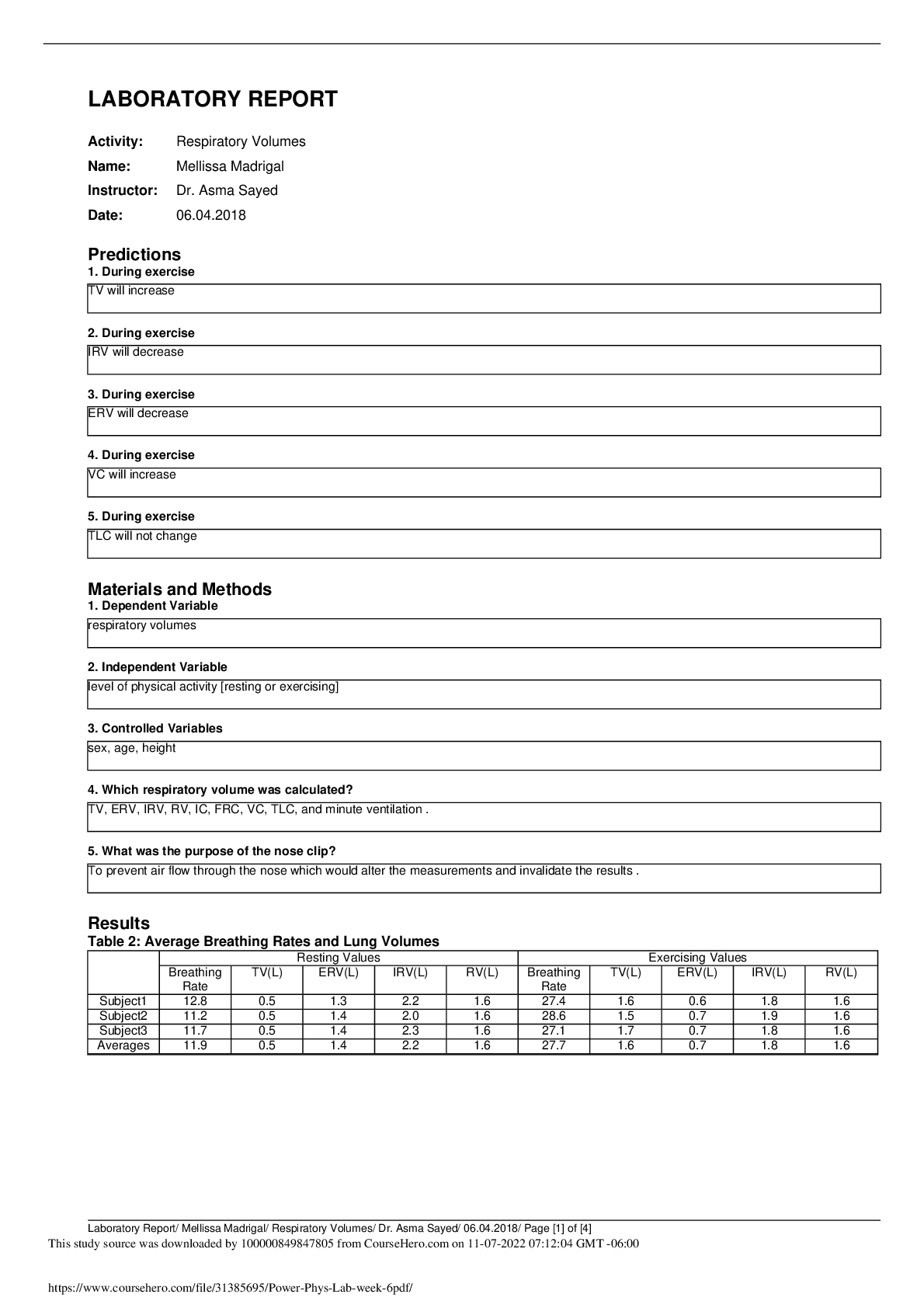

1. Summary

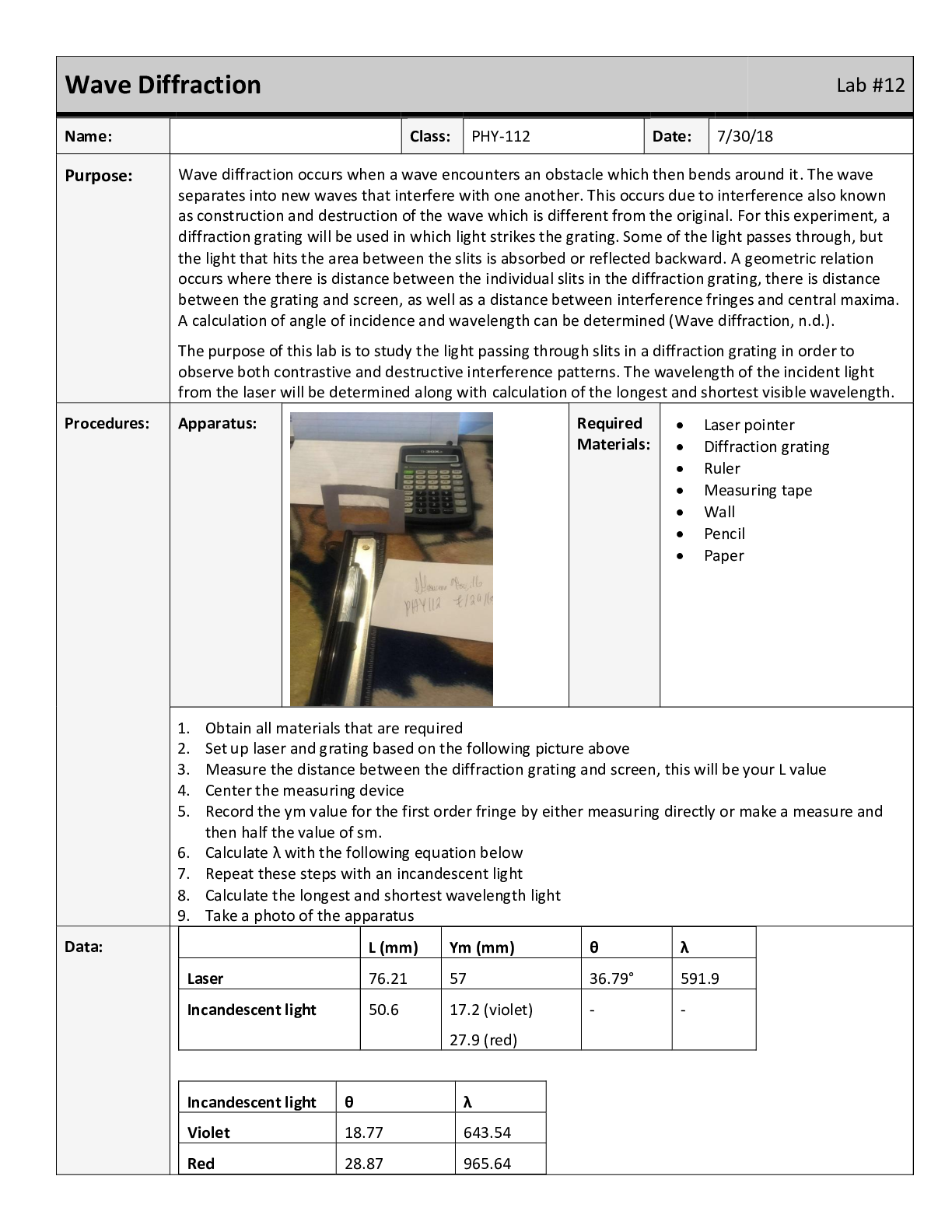

The purpose of this experiment is to examine the flaws and/or changes in each of the ten (10)

specimens provided. We conducted three (3) different types of tests. We performed a Visual

Test looking over each specimen and weld. We performed a Magnetic Test on specimens 1,

5, and 10. We also performed a Liquid Penetrant Test on all the specimens. We recorded the

imperfections during each test and evaluated why these flaws may have occurred.

2. Procedure

For each of the 10 specimens we performed various tests. The three tests that were performed

were a visual test, magnetic particle test, and liquid penetrant spray test.

Visual test

• We started out by laying out each specimen.

• A wire brush was used to clean any dust or debris from the construction of these

specimens.

• Then each specimen was evaluated looking at the different welds and looking for any

inconsistencies or variations.

• We looked at the placement of different plates and look to see if they were flush or

aligned & if there was evenness in the plates, surfaces or welds.

• We looked to see if the welds were good and/or if the plates were uniform. We look

to see if there are any lumps in the welds.

• We measured each Specimen to get the length of the welds and specimens we will be

evaluating.

Magnetic particle Testing

(Specimens 1, 5 & 10)

• Each specimen was clean with a wire brush to make sure that there is no dust or

debris.

• Iron powder was poured over the welds

• The powder was spread out over the welds by fingers to make sure it’s fully covering

each weld.

• We made sure to hold down the specimen firmly before turning on the contour probe.

• The contour probe is turned on and rotated over the specimen to activate the iron

powder. The powder then maneuvered over the welds to show possible imperfections

or cracks in the weld.

• This process was repeated for each of the three specimens tested.

Liquid Penetrant Spray

• We made sure that any dust or debris was removed from each specimen with a wire

brush prior to commencement of this test.

• The SKC-S aerosol cleaner spray what is applied to each specimen.

• The SKL-SP2 aerosol penetrating spray was then applied to each specimen at each

weld location.

• Once the Penetrant Spray is applied to all specimens it is necessary to wait for a dwell

time of 10 minutes before moving to the next step.

[Show More]

.png)

.png)

.png)