Engineering > QUESTIONS & ANSWERS > University of Florida - EML 4321: Exam-final EML 4321: Manufacturing Engineering (All)

University of Florida - EML 4321: Exam-final EML 4321: Manufacturing Engineering

Document Content and Description Below

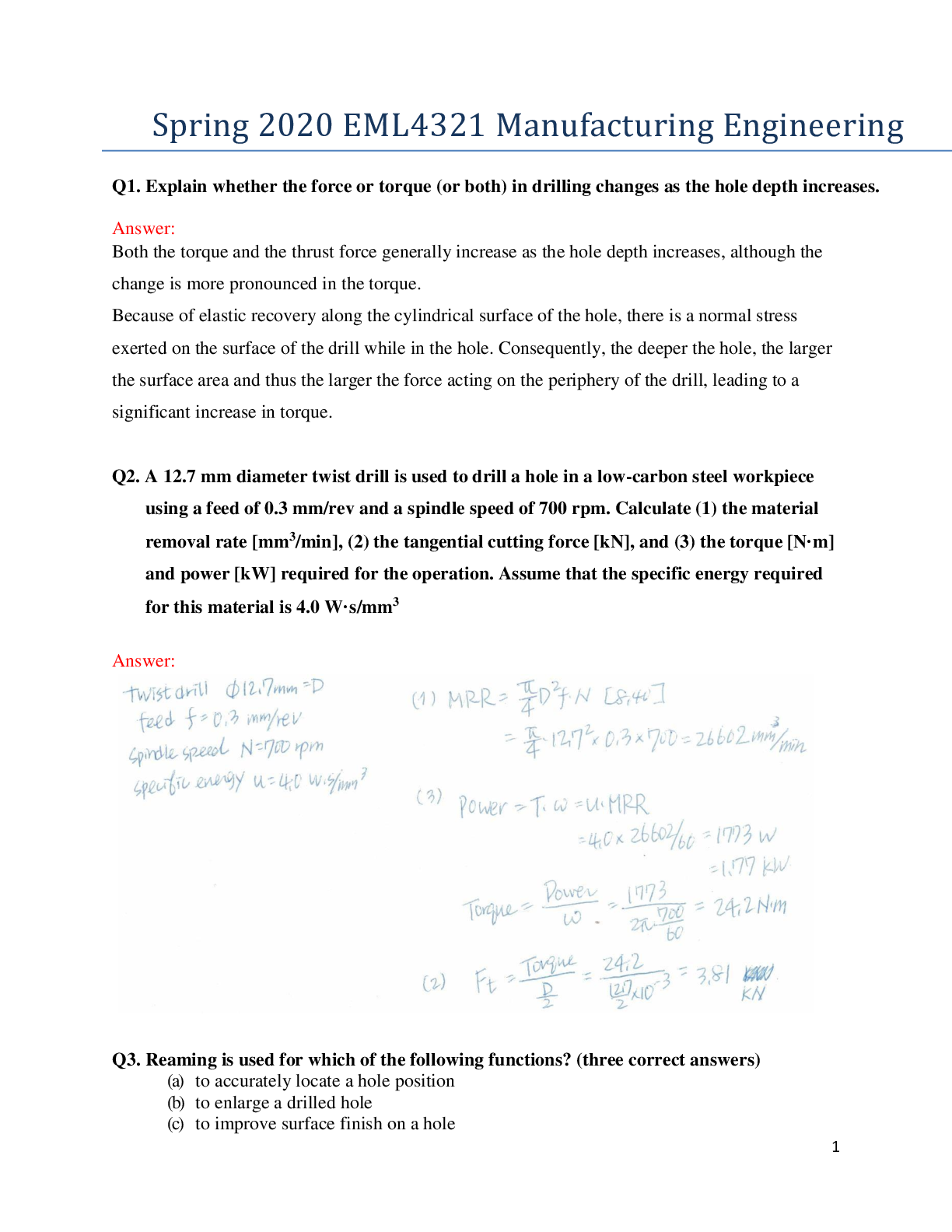

Last four digits of UFID Number: FINAL EXAM ANSWER KEY The time limit of 120 minutes will be strictlv enforced. It is your responsibility to complete this long exam within that time frame. ... Please work efficiently and accurately. Choose the best or closest answer. Open book, open notes. (However, waste time with written materials at your own risk!) Scientific calculators are the only type of electronic devices which may be used. CIRCL the correct answer. You will be graded solely upon what you circle. You should ave one circle for each “*”. You should have a total of sixty circles. 1A Los Alarnos National Laborato Chemistry Division 8A O * What welding rod will produce the strongest weld? * Which of the following terms does NOT describe the same process as the other terms ** Consider the Taylor tool life equation v h°b'T=C - which exponent is usually the smallest? - changing the feed on a lathe while turning will affect which variable? * Which uncoated cutting tool material should be used to cut steel? * Which will have the greatest HAZ? * What metal powder is used in the thermit process? * BUE can often be reduced or eliminated by * Which material is most likely to be cut with a negative rake angle? * If n' 0›27 F, , what is § ? *** A keyway 5 mm wide is broached. The step is 0.05 mm. Four teeth cut simultaneously. - What is the metal removal rate (cm3/min) if you are broaching at 20 m/min? - What is the force (N) needed to pull the broach if you are broaching 1020? - Which set of teeth on the broach cuts first? ** A Ti-6A1-4V milling operation has a MRR of 50 cm'/min. - What is K (N/mm2)? - How much power (kW) is needed? ** With regard to the movie you saw in class on automobile assembly - What automobile model was being assembled? - Which of the following processes was most featured? ** EDM has two basic types. One type is “sinker”. - Which of the following materials is NOT commonly used as a sinker electrode? - The other NOT sinker) type of EDM is * Which of the following is least likely to have been formed by broaching? *****'In our computer program to calculate the temperature withiri the chip - “k” is changed to “k+1” for what variable within the equations in order to improve convergence and stability? - the heat transfer is modeled as being - compared to the results you obtained from your program, accounting for heat transfer between the chip and the tool will result in the chip temperatures being - if the undeformed chip thickness is “h”, the maximum friction power was assumed to occur over a length of - in your computer program, changing the value of “b” would result in * Which material has the lowest thermal diffusivity? * HSS tools will soften if they are heated above what temperature (°C)? * Which process (borrowed from electronics manufacturing) produces tool coatings with the sharpest edges? * When optimizing cutting speed, the cutting speed which minimizes part cost will be the cutting speed which minimizes production time * Which one of the following is NOT a concept from Boothroyd’s Design for Assembly? build on a base part insert from only one direction minimize the number of parts provide chamfers * Due to RoHS, Pb alloys are now often being replaced with alloys high in Au Ag Hg Mg Ti Zn * During spot welding, you want to run 5 kA of current through a 0.1 md resistance. What power (kW) is needed? 0.0005 0.0006 0.0007 0.005 0.006 0.007 0.05 0.06 0.07 0.5 0.6 0.7 ** Based upon Figure 11.69a (copied below), - what is R/E? EI - What is the system output? G 1/(1+GH) bt( ITl p a) * When hot rolling a slab with two-foot diameter rolls and a coefficient of friction of 0.3, what is the maximum draft (in.)? 0.18 0.3 0.4 * What is the separating force (MN) on a roll if .the width of the sheet being rolled is 2 m .the diameter of the rolls is 1 m , .the draft is 3 mm = , p .the yield strength of the rolled material is 100 MPa 0.042 0.36 0.72 3.6 13 * Which of the following terms is NOT used in expendable mold casting * * Which type of metal tends to be most ductile? **** Which steel is - free-machining - hypereutectoid 302 4140 H-13 W1 - a tool steel most likely used for making a twist drill for drilling holes in an automobile factory - a hypoeutectoid steel that is NOT BCC * “Triple nickel” is what kind of alloy? * Which of the following is more of a function of the fiber in a composite (NOT a function of the matrix)? * The graphite particles are vermicular in what type of iron? * What characterizes plane strain? * What is the pressure condition at the exit when extruding? * Which type of alloy is more likely to be extruded? * As you are proceeding in facing a solid shaft on a lathe, if the spindle turns at a constant speed, the cutting speed du ly decreases remains the same gradually increases * A two-inch shaft is being turned at 2000 rpm. What is the cutting speed (SFM)? * What would be the typical atmosphere when HIPing? CO HC1 2 * When line balancing, positive zoning means two elements should be scheduled at different workstations elements should be scheduled in order of precedence largest elements should be scheduled first minimum rational work elements are used * A hammer with a 600 kg mass is raised three meters. How much potential energy (kJ) is available? 1.8 2.1 2.4 6 7 8 11 21 24 * Doubling the diameter of a spherical casting will cause the solidification time to approximately remain unchan ed increase 1.41 times p double increase 8 times I * Which of these two material classes m e typically be remelted and recast? * Which of the following processes is more common when dealing with plastics? broaching drawing nje tion olding rolling ** Using the industry-standard method, you are punching two holes of three-inch diameter in 0.1046” thick steel sheet with an ultimate tensile strength of 30,000 psi. - how much force (tons) is needed to punch the holes simultaneously? - 9.4 11 16 32 41 62 83 131 - beveling the punches will do what to the needed force? ** You are upsetting a cylindrical workpiece with a diameter of 1 m, and a height of 0.5 m. - If the yield strength is 110 MPa and you have sticking friction, what is the maximum pressure (MPa) on the die? _ 110 120 130 140 150 160 170 180 200 220 260 280 360 400 430 - Which are you likely performing? cold forging ot forging [Show More]

Last updated: 2 years ago

Preview 1 out of 10 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$14.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Jun 24, 2020

Number of pages

10

Written in

Additional information

This document has been written for:

Uploaded

Jun 24, 2020

Downloads

0

Views

376

.png)

.png)

.png)

.png)

.png)

.png)

.png)