Engineering > QUESTIONS & ANSWERS > University of Florida - EML 4321: Spring 2020 EML4321 Manufacturing Engineering. All Worked Solution (All)

University of Florida - EML 4321: Spring 2020 EML4321 Manufacturing Engineering. All Worked Solutions.

Document Content and Description Below

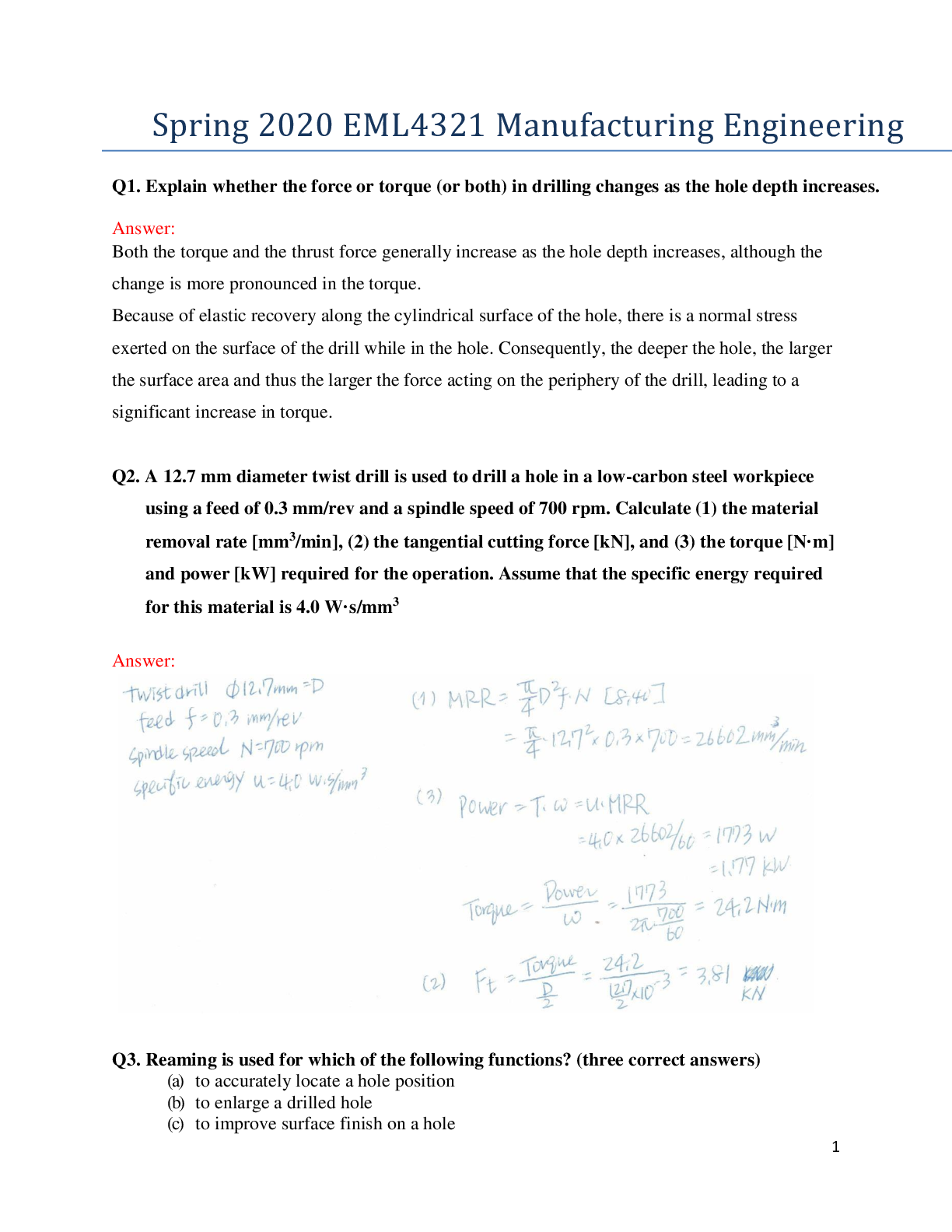

Spring 2020 EML4321 Manufacturing Engineering Q1. Explain whether the force or torque (or both) in drilling changes as the hole depth increases. Q2. A 12.7 mm diameter twist drill is used to dri... ll a hole in a low-carbon steel workpiece using a feed of 0.3 mm/rev and a spindle speed of 700 rpm. Calculate (1) the material removal rate [mm3/min], (2) the tangential cutting force [kN], and (3) the torque [N•m] and power [kW] required for the operation. Assume that the specific energy required for this material is 4.0 W•s/mm3 Q3. Reaming is used for which of the following functions? (three correct answers) (a) to accurately locate a hole position (b) to enlarge a drilled hole (c) to improve surface finish on a hole (d) to improve accuracy on hole diameter (e) to make an internal thread Q4. Explain why drilling, boring, and reaming of large holes is generally more accurate than just drilling and reaming. Q5. Describe the relative characteristics of climb milling and up milling. Q6. Assume that in the face-milling operation shown in Fig. 8.53 of the course textbook, the workpiece dimensions are 200 mm by 500 mm. The cutter is 150 mm in diameter, has 8 teeth, and rotates at 300 rpm. The depth of cut is 3 mm and the feed is 0.125 mm/tooth. Assume that the specific energy required for this material is 5.5 W•s/mm3 and that 75% of the cutter diameter is engaged during cutting. Calculate (1) the material removal rate [mm3/min], (2) the power [kW] required, and (3) the cutting time [min]. Q7. Would you recommend broaching a keyway on a gear blank before or after the teeth are machined? Explain. Q8. What are the effects of a wear flat on the grinding operation? Q9. Describe the advantages of superabrasives over conventional abrasives. Q10. Explain the consequences of allowing the workpiece temperature to rise excessively in grinding operations. Q11. Example 9.2 of the course textbook: Assume that you are performing a surface-grinding operation on a low-carbon steel workpiece using a wheel of diameter D = 250 mm that rotates at N = 4000 rpm. The width of cut is w = 25 mm, depth of cut is d = 0.05 mm, and the feed rate of the workpiece is v = 1.5 m/s. Calculate the cutting force Fc (the force tangential to the wheel) and the thrust force Fn (the force normal to the workpiece), noting that in general Fn is around 30% higher than Fc. [Show More]

Last updated: 2 years ago

Preview 1 out of 4 pages

Buy this document to get the full access instantly

Instant Download Access after purchase

Buy NowInstant download

We Accept:

Reviews( 0 )

$11.00

Can't find what you want? Try our AI powered Search

Document information

Connected school, study & course

About the document

Uploaded On

Jun 24, 2020

Number of pages

4

Written in

Additional information

This document has been written for:

Uploaded

Jun 24, 2020

Downloads

0

Views

108

.png)

.png)

.png)

.png)

.png)

.png)

.png)